Plastic profile with triangular cavity and its composite material

A technology of plastic doors and windows and composite materials, applied in windows/doors, building components, buildings, etc., can solve problems such as structural performance, thermal insulation performance, structural strength, deformation performance defects, etc., to increase noise reduction and sound absorption Ability, excellent performance, and the effect of improving the flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

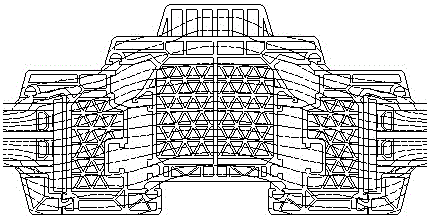

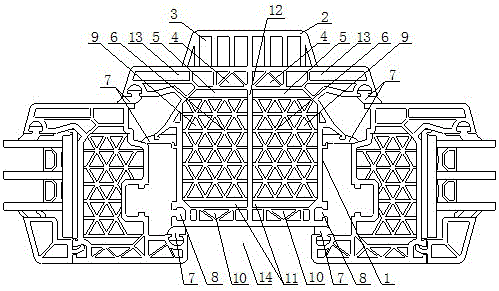

Image

Examples

Embodiment 1

[0025]1. A composite material for making plastic door and window profiles, which comprises the following components in parts by weight: 100 parts of PVC resin, 4 parts of barium stearate, 2 parts of nano graphite particles through surface physical modification, chlorine 6 parts of polyethylene; 5 parts of titanium dioxide, 5 parts of activated calcium carbonate, 1.5 parts of monoglyceride stearate, 3 parts of polyacrylate, and 0.5 parts of expanded vitrified microbeads surface-modified with trimethylchlorosilane .

[0026] 2. Use the expanded vitrified microbeads produced by Weifang Chuangzhi New Material Co., Ltd., with a particle size of 3 .

[0027] 3. Nano-graphite particles with surface physical modification adopt 70-80 parts of nano-graphite powder with continuous particle size distribution of 0.8um-38um and 20-30 parts of polyethylene to compound and mix, through a single-screw mixer at 150±5 Under the conditions of ℃ and 4MPa pressure, extrude and cool to produce roun...

Embodiment 2

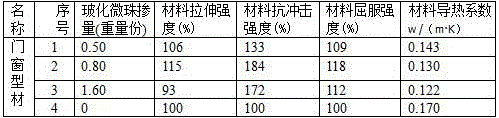

[0031] The similarities between this embodiment and Embodiment 1 will not be repeated. The difference is that when producing door and window profiles: according to the following parts by weight: 100 parts of PVC resin, 4 parts of barium stearate, nano 2 parts of graphite particles, 6 parts of chlorinated polyethylene; 5 parts of titanium dioxide, 5 parts of activated calcium carbonate, 1.5 parts of monoglyceride stearate, 3 parts of polyacrylate, and the expansion of surface modification with trimethylchlorosilane 0.8 parts of vitrified microspheres, mix the above mixture evenly, and extrude the door and window profiles by using known door and window profile extrusion equipment and process. The results are shown in Table 1 compared with the current door and window profile plan without adding expanded vitrified beads.

Embodiment 3

[0033] The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is that when producing door and window profiles: according to the following components in parts by weight: 100 parts of PVC resin, barium stearate (4 parts, through surface physical modification 2 parts of nano graphite particles, 6 parts of chlorinated polyethylene; 5 parts of titanium dioxide, 5 parts of activated calcium carbonate, 1.5 parts of monoglyceride stearate, 3 parts of polyacrylate, surface modified with trimethylchlorosilane 1.6 parts of expanded vitrified microspheres, the above mixture is mixed evenly, and the known door and window profile extrusion equipment and process are used to extrude the production of door and window profiles. Compared with the current door and window profile scheme that does not add expanded vitrified microspheres, the results are shown in the table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com