Anti-static halogen-free flame-retardant polypropylene composition and preparation method

A flame-retardant polypropylene and antistatic technology, which is applied in the field of halogen-free flame-retardant polypropylene composition and its preparation, can solve the problems of decreased physical properties, poor antistatic durability, and large dependence on environmental humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

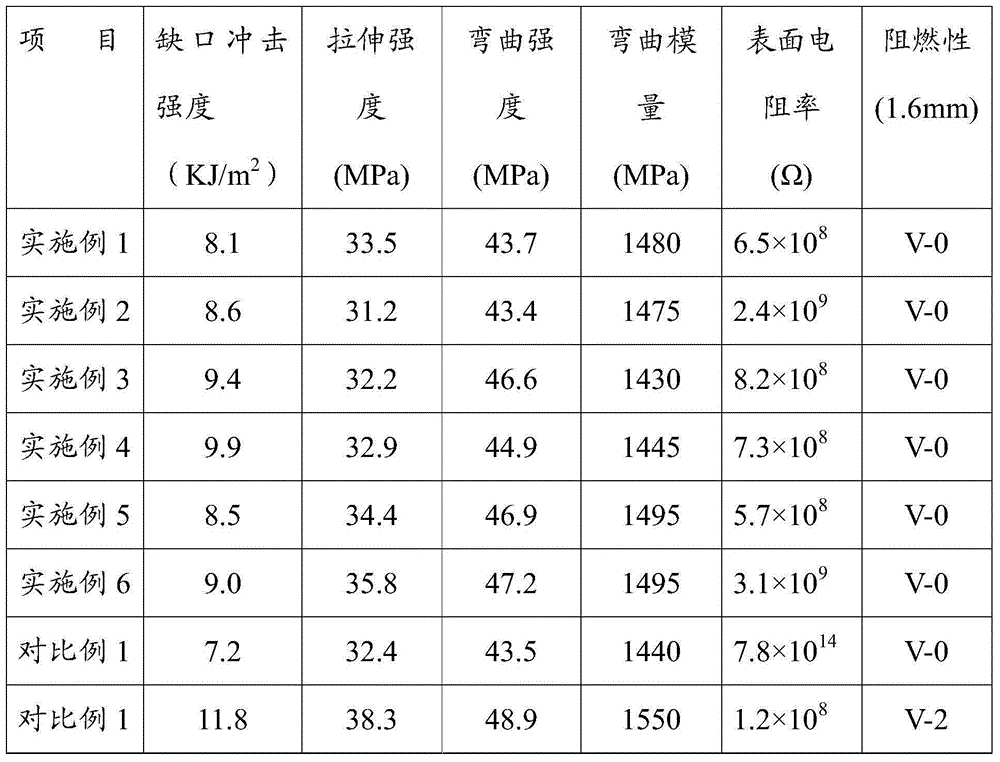

Examples

Embodiment 1

[0023] 52.6 parts by weight of polypropylene (melt flow rate is 6g / 10min), 6 parts by weight of antistatic agent (medium-mold high-strength carbon fiber powder), surface treatment agent (γ-glycidyl-oxypropyl-trimethoxysilane and diphenol-based propane diglycidyl ether in a weight ratio of 3:1) 1.2 parts by weight, 30 parts by weight of a composite phosphorus-nitrogen flame retardant, 3 parts by weight of a flame-retardant synergist (sodium-based montmorillonite), and a carbon-forming cooperative 3 parts by weight of effect agent (hyperbranched polycaprolactam), 3 parts by weight of polar modifier (polypropylene grafted maleic anhydride), 3 parts by weight of antioxidant (tetra[β-(3,5-di-tert-butyl-4-hydroxy Phenyl) propionic acid] pentaerythritol ester, 3,3-dilauryl thiodipropionate and tris (2,4-di-tert-butylphenyl) phosphite by weight ratio 0.5:0.5:1) 0.6 weight 0.6 parts by weight of processing aids (zinc stearate, erucamide and ethylene bisstearamide in a weight ratio of 1...

Embodiment 2

[0025]52.6 parts by weight of polypropylene (melt flow rate is 6g / 10min), 6 parts by weight of antistatic agent (general-purpose carbon fiber powder), surface treatment agent (γ-glycidyl-oxypropyl-trimethoxysilane and two 1.2 parts by weight of phenolic propane diglycidyl ether (3:1) by weight, 30 parts by weight of compound phosphorus nitrogen flame retardant, 3 parts by weight of flame retardant synergist (sodium montmorillonite), charcoal synergist (hyperbranched polycaprolactam) 3 parts by weight, polar modifier (polypropylene grafted maleic anhydride) 3 parts by weight, antioxidant (tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl ) propionic acid] pentaerythritol ester, 3,3-dilauryl thiodipropionate and three (2,4-di-tert-butylphenyl) phosphite by weight ratio 0.5:0.5:1) 0.6 parts by weight, Processing aid (zinc stearate, erucamide and ethylene bisstearamide in a weight ratio of 1:1:1) 0.6 parts by weight. Add it to a high-speed mixer at a speed of 500 rpm and mix for 3 mi...

Embodiment 3

[0027] 54.6 parts by weight of polypropylene (melt flow rate is 6g / 10min), 6 parts by weight of antistatic agent (medium-mold high-strength carbon fiber powder), surface treatment agent (γ-glycidyl-oxypropyl-trimethoxysilane and diphenol-based propane diglycidyl ether in a weight ratio of 3:1) 1.2 parts by weight, 28 parts by weight of a composite phosphorus-nitrogen flame retardant, 3 parts by weight of a flame-retardant synergist (sodium montmorillonite), and a carbon-forming cooperating agent 3 parts by weight of effect agent (hyperbranched polycaprolactam), 3 parts by weight of polar modifier (polypropylene grafted maleic anhydride), 3 parts by weight of antioxidant (tetra[β-(3,5-di-tert-butyl-4-hydroxy Phenyl) propionic acid] pentaerythritol ester, 3,3-dilauryl thiodipropionate and tris (2,4-di-tert-butylphenyl) phosphite by weight ratio 0.5:0.5:1) 0.6 weight 0.6 parts by weight of processing aids (zinc stearate, erucamide and ethylene bisstearamide in a weight ratio of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com