Low-VOC and antistatic polypropylene material as well as preparation method and application thereof

A polypropylene material and antistatic technology, applied in the field of polymer materials, can solve the problems of reducing the impact performance of polypropylene modified materials, not being able to effectively avoid VOC volatilization, and other performance degradation of materials, achieving low VOC, broad market prospects and Excellent application value and tactile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~3

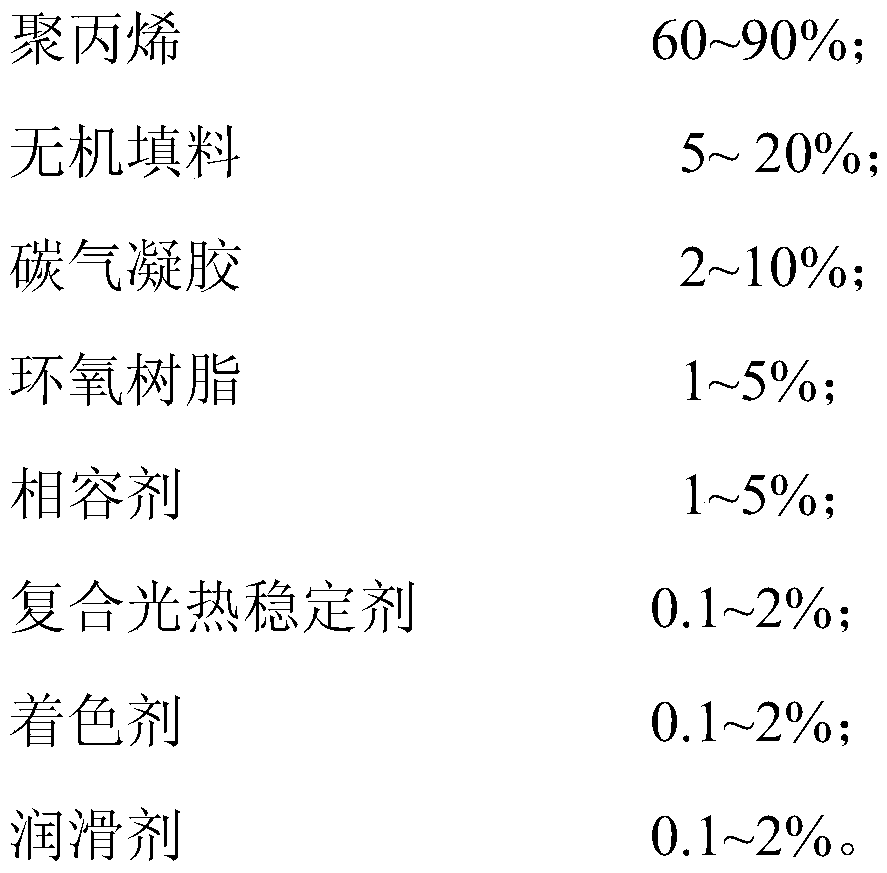

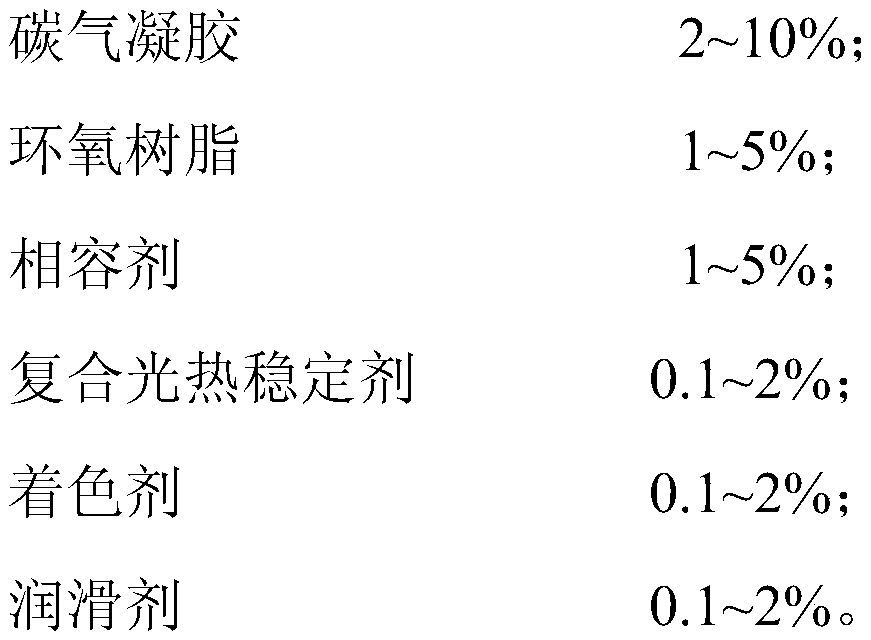

[0049] Polypropylene, epoxy resin, talcum powder, compatibilizer, lubricant, composite light and heat stabilizer (using antioxidant 1010, antioxidant 168 and light stabilizer 770, light stabilizer 944) Composite), and add coloring agent, after high-speed mixing 2min in high-speed mixer, add in the twin-screw extruder from main feeding feeder, carbon aerogel and the talc powder that account for 10% of talc gross mass mix at high speed After 3 minutes, feed into the twin-screw extruder from the side feeding feeder; the temperature of the twin-screw extruder from the feeding section to the die head is as follows: 190°C, 220°C, 220°C, 220°C, 220°C, 220°C ℃, 220℃, 220℃, the temperature of the die head is 220℃, after 4 hours of double vacuum extraction, head extrusion, drawing, air cooling, pelletizing, and hot blast circulation, it is packaged after drying to obtain low VOC , Antistatic black automotive polypropylene material.

[0050] The component prescription of table 2 embodim...

Embodiment 4

[0054] After the compatibilizer is added in Example 4, the rigidity of the material is improved, and the TVOC still meets the standard requirements. In Example 5, a polar epoxy resin is added, and it can be clearly seen that the surface resistivity of polypropylene after the epoxy resin is added increases. , TVOC decreases, it can be seen that there is a strong affinity between carbon airgel and epoxy resin, which can more effectively disperse carbon airgel in polypropylene resin and enhance the adhesion of the two-phase interface. Improve the performance of materials in all aspects.

[0055] The addition of carbon airgel in the present invention not only maintains the mechanical properties of the material, but also maintains its better TVOC performance and permanent antistatic performance without significantly increasing the density. While the mechanical properties of the material are further improved after adding epoxy resin, the TVOC performance is better.

[0056] Table 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com