Functional polyester and cotton conductive fabric

A functional, polyester-cotton technology, applied in the field of textiles, can solve the problems of weakening, disappearing, and short duration of antistatic properties, and achieve the effects of reasonable structure, permanent antistatic properties, and comfortable hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

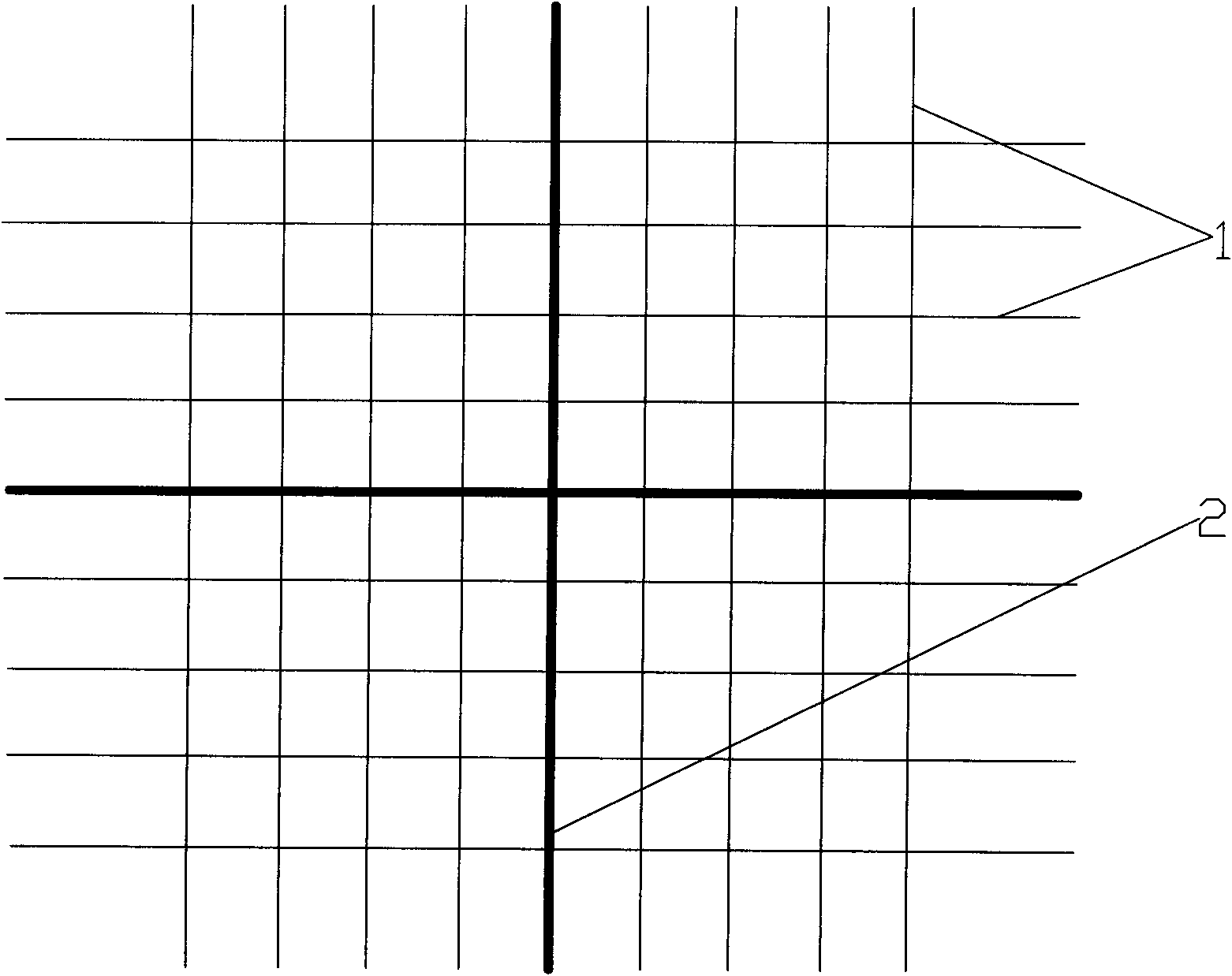

[0011] As shown in the figure, a functional polyester-cotton conductive fabric is formed by vertical interweaving of warp and weft yarns, the warp and weft yarns are composed of polyester-cotton blended yarn 1 and conductive fiber yarn 2, and the conductive fiber yarn 2 is Arranged evenly at intervals, the warp density of the functional polyester-cotton conductive fabric is 380 threads / 10cm, the weft density is 260 threads / 10cm, and the arrangement quantity ratio of the polyester-cotton blended yarn 1 and the conductive fiber yarn 2 is 30:1.

Embodiment 2

[0013] As shown in the figure, a functional polyester-cotton conductive fabric is formed by vertical interweaving of warp and weft yarns, the warp and weft yarns are composed of polyester-cotton blended yarn 1 and conductive fiber yarn 2, and the conductive fiber yarn 2 is Arranged evenly at intervals, the warp density of the functional polyester-cotton conductive fabric is 400 threads / 10cm, the weft density is 270 threads / 10cm, and the arrangement quantity ratio of the polyester-cotton blended yarn 1 and the conductive fiber yarn 2 is 32:1.

Embodiment 3

[0015] As shown in the figure, a functional polyester-cotton conductive fabric is vertically interwoven with warp and weft yarns, the warp and weft yarns include polyester-cotton blended yarn 1 and conductive fiber yarn 2, and the conductive fiber yarn 2 is uniform Arranged at intervals, the warp density of the functional polyester-cotton conductive fabric is 420 strands / 10cm, the weft density is 280 strands / 10cm, and the arrangement number ratio of the polyester-cotton blended yarn 1 and the conductive fiber yarn 2 is 40 : 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com