Spun dyeing meta-aramid short fiber and its preparation process

A technology for dyeing aramid staple fiber and stock solution, which is applied in the direction of spinning solution preparation, wet spinning method, and adding pigments to spinning solution, which can solve the influence of fiber dyeing performance, application limitations of meta-aramid fibers, and dyeing difficulties And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention are given below to illustrate the present invention, but should not be regarded as limiting the present invention.

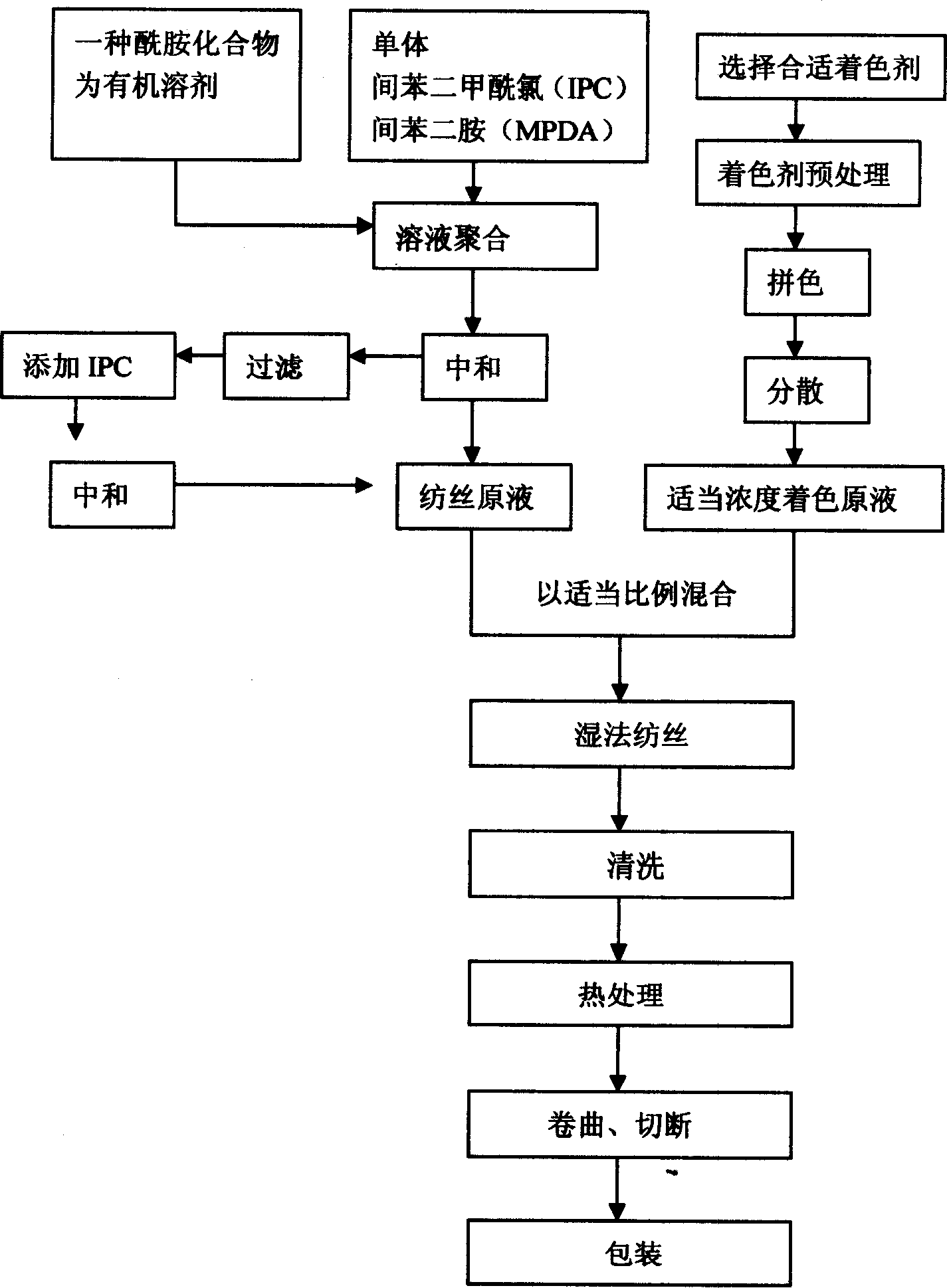

[0032] according to figure 1 As shown, the preparation method of the dope dyed meta-aramid staple fiber in this embodiment is implemented according to the following procedures:

[0033] 1. Carry out solution polymerization with monomer m-phenylenediamine and monomer isophthaloyl chloride (IPC) in a system where an amide compound is an organic solvent, and use anhydrous NH 3 Carry out pre-neutralization, filter the obtained ammonium chloride, add IPC for the second time, and neutralize to obtain the spinning stock solution;

[0034] The spinning solution used before wet spinning is a low-salt spinning solution, and isophthaloyl chloride is added twice during the polymerization reaction to make the inherent viscosity of the spinning stock solution ≥ 2;

[0035] A, after adding isophthaloyl chloride for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com