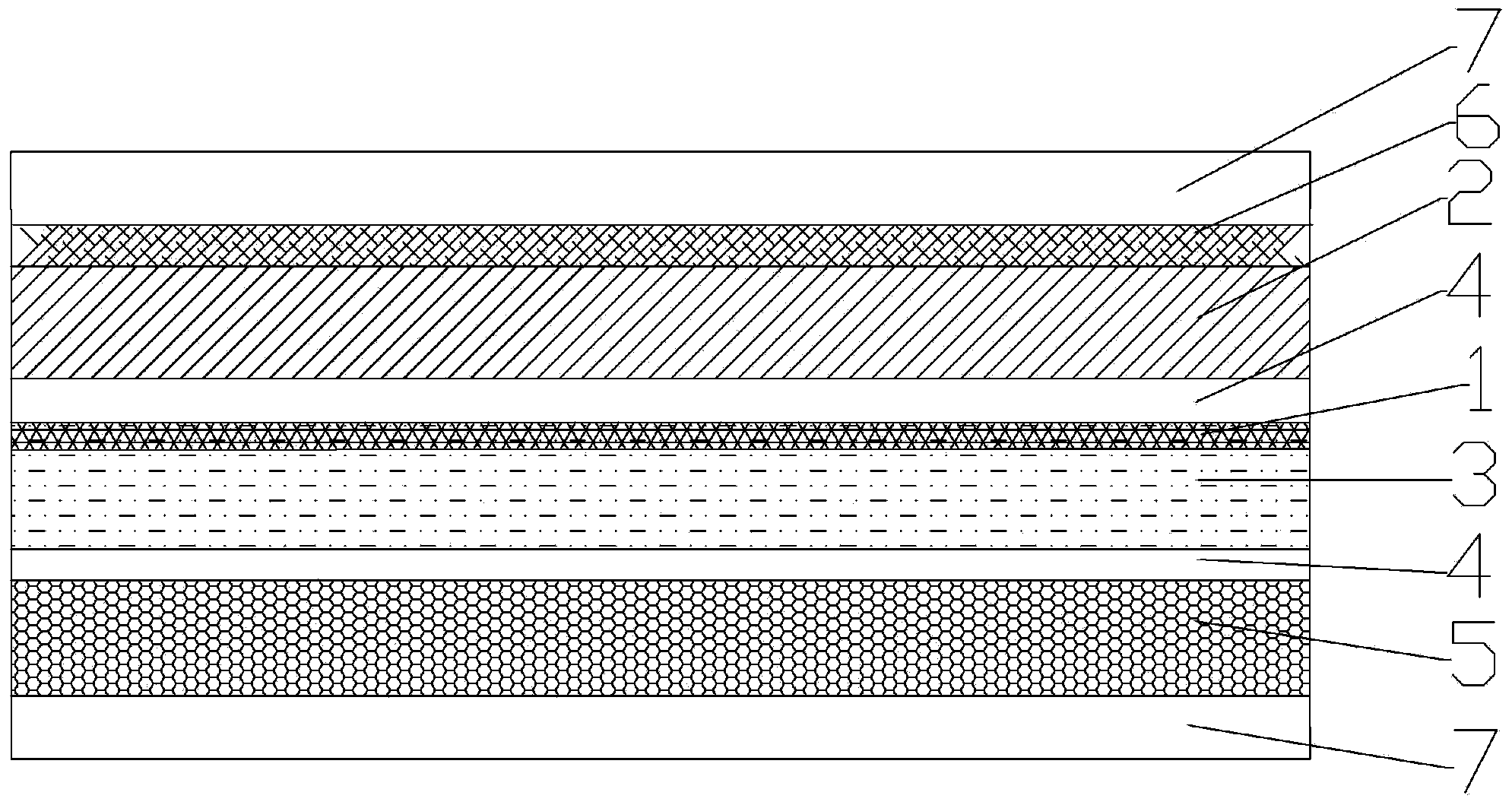

Composite bulletproof plate containing adhesive-bonding synergistic layer and manufacturing method thereof

A ballistic board and bonding technology, applied in the direction of chemical instruments and methods, layered products, armor plate structure, etc., can solve the problems of poor wettability, poor composite strength, etc., and achieve the improvement of continuous bullet resistance performance and increase Quantity, the effect of increasing composite strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

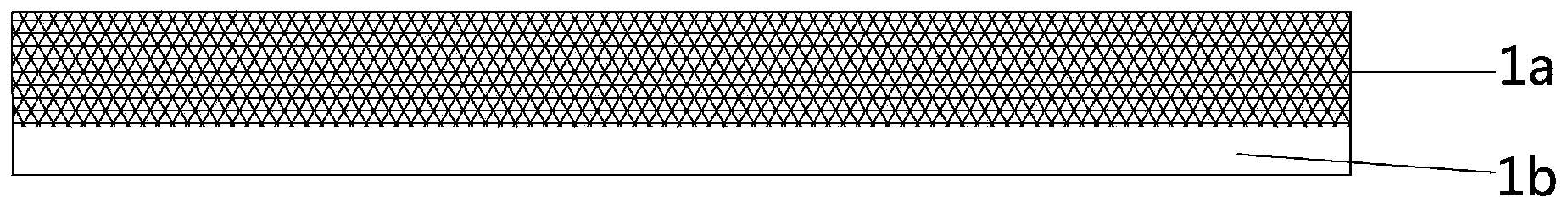

Embodiment 1

[0019] The synergistic woven fabric (ultra-high molecular weight polyethylene fiber and aramid fiber 1414 fiber volume ratio 50:50, surface density 200g / m 2 , coated with 30g / m on one side 2 Acrylic film) and an areal density of 185g / m 2 The ultra-high molecular weight polyethylene fiber non-weft cloth containing acrylate resin is cut into a rectangle of 250mm×300mm. Laminate 36 layers of ultra-high molecular weight polyethylene fiber non-weft cloth and 1 layer of synergistic woven fabric. The synergistic woven fabric is placed on the side that will be bonded to the ceramic, and the side without the adhesive film is facing outward, 80°C After preheating, it was hot-pressed at 120°C and 17MPa for 50 minutes, and then cooled to room temperature and taken out to become a single-curved laminate. Then apply glue on both sides, the side with the synergistic layer is bonded to the 9.5mm thick silicon carbide ceramic plate, the other side is bonded to the buffer layer, and then the ...

Embodiment 2

[0021] The synergistic woven fabric (ultra-high molecular weight polyethylene fiber and glass fiber volume ratio 70:30, surface density 250g / m 2 , coated with 40g / m on one side 2 polyethylene film) and an areal density of 185g / m 2 The ultra-high molecular weight polyethylene fiber non-weft cloth containing polyethylene resin is cut into a rectangle of 250mm×300mm. Laminate 47 layers of ultra-high molecular weight polyethylene fiber non-weft cloth and 1 layer of synergistic woven fabric. The synergistic woven fabric is placed on the side that will be bonded to the ceramic, and the side without the adhesive film is facing outward, 80°C After preheating, it was hot-pressed at 120°C and 17MPa for 50 minutes, and then cooled to room temperature and taken out to become a single-curved laminate. Then apply glue on both sides, the side with the synergistic layer is bonded to the 7mm thick silicon carbide ceramic plate, the other side is bonded to the buffer layer, and then the arami...

Embodiment 3

[0023] Synergistic woven fabric (high molecular weight polyethylene fiber and carbon fiber volume ratio 60:40, surface density 180g / m 2 , coated with 30g / m on one side 2 Acrylic film) and an areal density of 185g / m 2 The ultra-high molecular weight polyethylene fiber non-weft cloth containing acrylate resin is cut into a square of 500mm×500mm. Laminate 37 layers of ultra-high molecular weight polyethylene fiber non-weft cloth and 1 layer of synergistic woven fabric. The synergistic woven fabric is placed on the side that will be bonded to the ceramic, and the side without the adhesive film is facing outward, 80°C After preheating, it was hot-pressed at 120°C and 17MPa for 50 minutes, and then cooled to room temperature and taken out to become a laminated plate. Then apply glue on the side with the synergistic layer, bond it with a 9.5mm thick silicon carbide ceramic plate, and then glue an aramid crack arresting layer on the outside of the ceramic, cure it at 50°C for 6 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com