Preparation method of aluminum plating composite film

A technology of aluminum-coated composite film and aluminum-coated film, which is applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve problems such as solvent residues, a large amount of waste solvents, and impacts on the ecological environment and human health. Good composite strength and tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of aluminized composite membrane, comprises the following steps:

[0025] Coating a solvent-free adhesive to the aluminum surface of the aluminized film, the glue amount of the solvent-free adhesive is 2.6g / m 2 ~3.0g / m 2 ;

[0026] Composite the aluminized film coated with the solvent-free adhesive and the outer film, and the composite tension during the composite is 45N~55N;

[0027] The obtained composite film is wound up;

[0028] The rolled composite film is subjected to aging treatment to obtain an aluminized composite film.

[0029] In the invention, firstly, the solvent-free adhesive is coated on the surface of the aluminum layer of the aluminized film, and then the aluminized film coated with the solvent-free adhesive is combined with the outer layer film, and the aluminized composite film is obtained after winding and aging treatment. The invention obtains an aluminum-coated composite film with good compos...

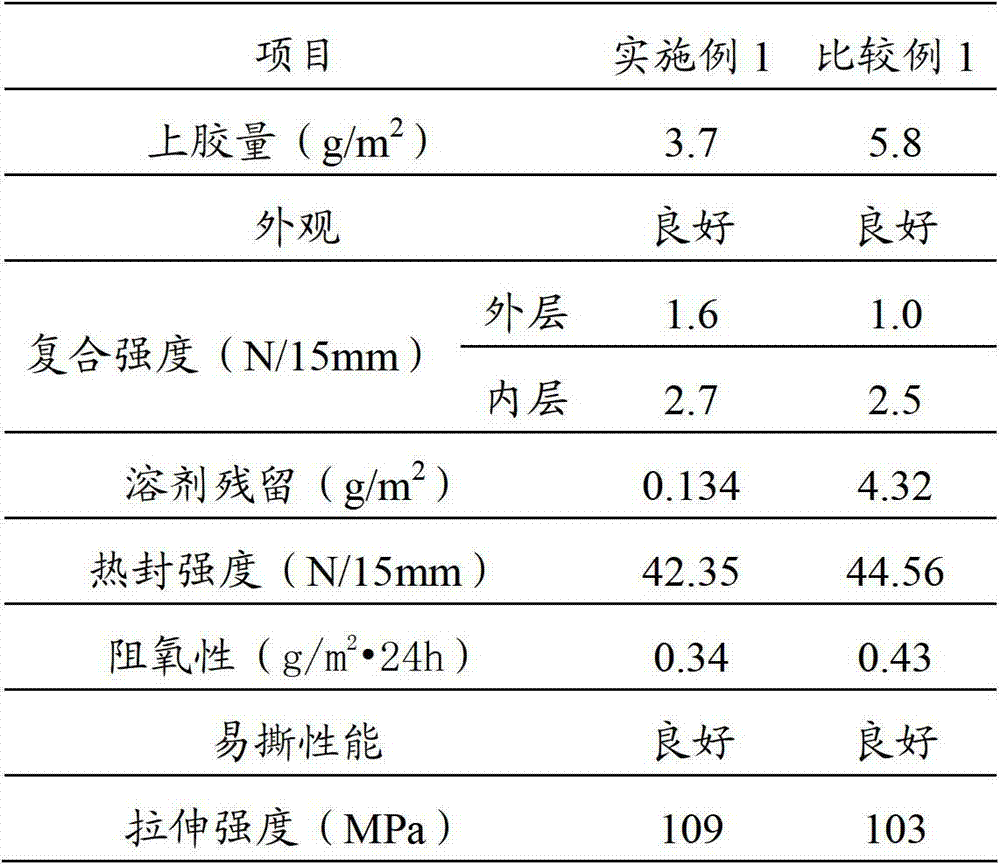

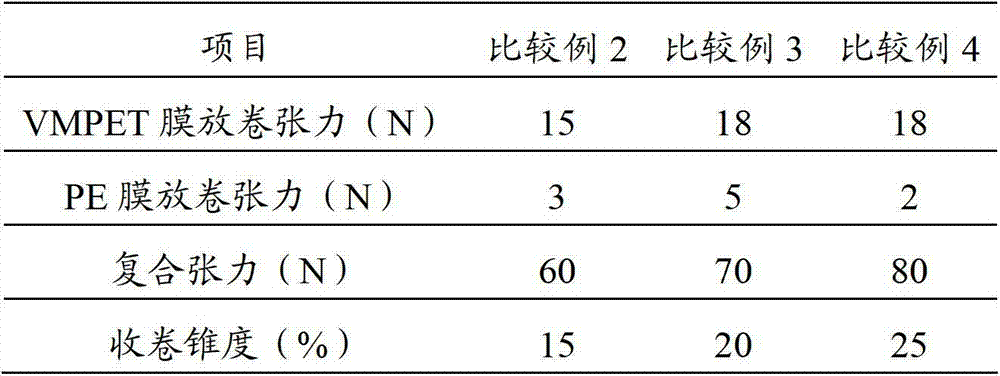

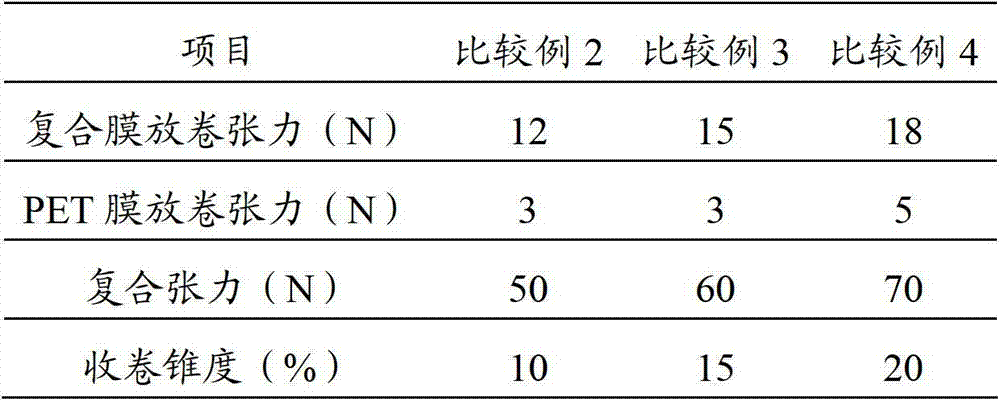

Embodiment 1

[0053] Using aluminized polyester film (VMPET) as the base material, apply two-component polyurethane adhesive on the surface of the aluminum layer of the VMPET film, the coating temperature is 50°C, and the amount of glue is 2.6g / m 2 , the unwinding tension of the VMPET film is 12N; the VMPET film coated with the adhesive is compounded with the PE film to obtain a composite film, the composite tension is 50N, and the unwinding tension of the PE film is 3N; 10%; the composite film after winding was cured for 30h at a humidity of 45RH% and a temperature of 50°C to obtain a 12VMPET / 40PE composite film;

[0054] Using the 12VMPET / 40PE composite film as the base material, apply a two-component polyurethane adhesive on the surface of the PET layer of the VMPET film, the coating temperature is 50°C, and the glue amount is 1.1g / m 2 , the unwinding tension of the composite film is 18N; the composite film coated with the adhesive is compounded with the PET film to obtain a composite fi...

Embodiment 2~9

[0073] Prepare 12PET / 12VMPET / 40PE composite film according to the raw materials, methods and steps provided in Example 1. The difference is that the amount of gluing is controlled according to Table 3. The composite strength of the obtained composite film is shown in Table 3. Table 3 is Example 2 of the present invention. ~9 Glue amount and composite strength of the composite film provided.

[0074] Table 3 The amount of gluing and the composite strength of the composite film provided by Examples 2 to 9 of the present invention

[0075]

[0076] In Table 3, in the composite films prepared in Examples 6-9, the aluminum layer transfer phenomenon appeared in the PET / VMPET layer.

[0077] In the invention, firstly, the solvent-free adhesive is coated on the surface of the aluminized film, and then the aluminized film coated with the solvent-free adhesive is combined with the outer layer film, and the aluminized composite film is obtained after winding and aging treatment. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unwind tension | aaaaa | aaaaa |

| Unwind tension | aaaaa | aaaaa |

| Glue amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com