Film magnetoelectric composite material and preparation method thereof

A magnetoelectric composite material and composite material technology, which are applied in the field of thin-film magnetoelectric composite materials and their preparation, can solve the problems of low magnetostriction of the ferromagnetic phase, influence the improvement of the magnetoelectric conversion coefficient of the material, etc., so as to improve the magnetoelectric coupling coefficient. , Improve high frequency performance, avoid the effect of eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

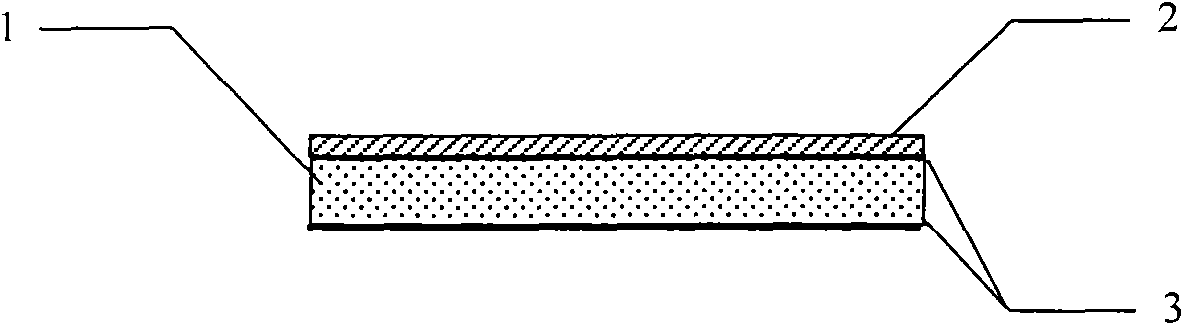

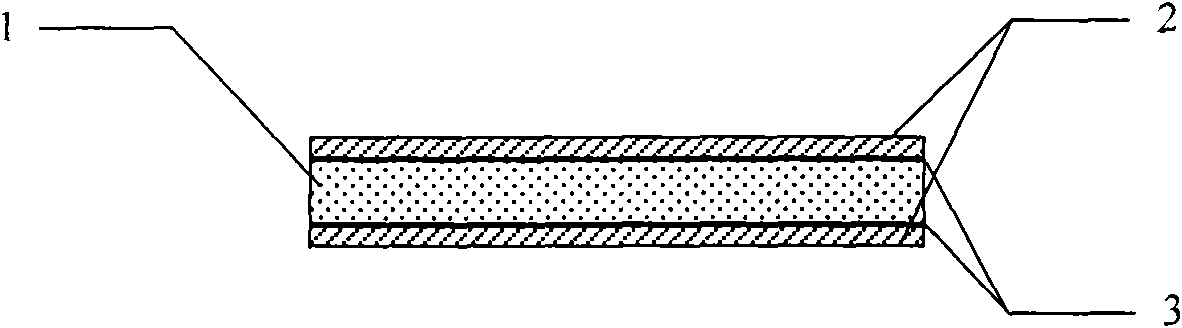

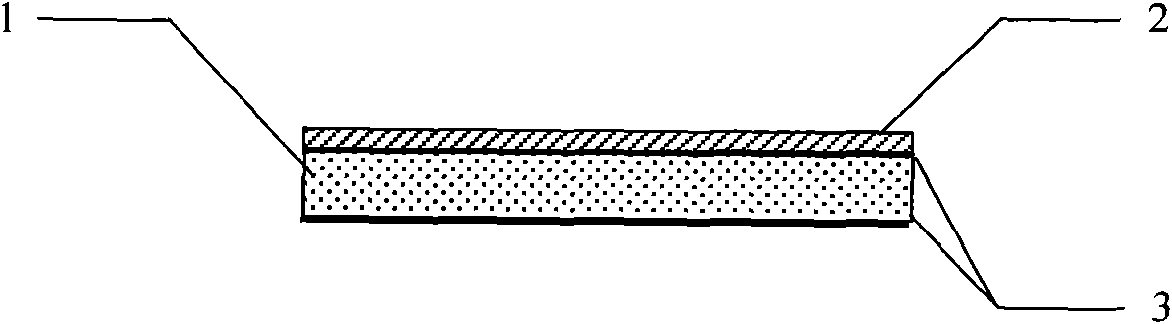

[0036] The preparation method of the magnetoelectric composite material of the present embodiment is: the composition is Pb[(Co 0.5 W 0.5 ) 0.2 Ti 0.45 Zr 0.35 ]O 3The piezoelectric ceramics were processed into thin slices with a size of 10×10×2.0 mm. After cleaning, Ag paste was brushed on both sides and fired to form conductive electrodes. The thickness of the electrodes was 100 μm, and the electrodes on both sides were welded with wires. Then, the piezoelectric substrate with the electrodes prepared is cleaned, and a layer of (Tb 0.2 Dy 0.8 )(Fe 0.80 co 0.10 mn 0.05 V 0.05 ) 1.80 The magnetostrictive film is annealed in situ at 450°C for 90min after the film is deposited. After the preparation of the material, the piezoelectric substrate was polarized along the thickness direction at 100° C. and a voltage of 3 kV / mm for 20 min. Then, under the conditions of a bias magnetic field of 500Oe, an alternating magnetic field of 1Oe, and an alternating magnetic field fr...

Embodiment 2

[0038] The preparation method of the magnetoelectric composite material of the present embodiment is: the composition is Pb[(Ba 0.5 Nb 0.5 ) 0.1 Ti 0. 45 Zr 0.45 ]O 3 The piezoelectric ceramics were processed into thin slices with a size of 10×10×0.2 mm. After cleaning, a layer of 0.001 μm Au conductive electrodes were sputtered on both sides, and wires were welded on both sides of the electrodes. Then, the piezoelectric substrate with the electrodes prepared is cleaned, and a layer of 0.01 μm thick (Tb 0.4 Dy 0.55 PR 0.05 )Fe 2.20 The magnetostrictive film was annealed in situ at 490°C for 10 minutes after the film was deposited. After the preparation of the material, the piezoelectric substrate was polarized along the thickness direction at 100° C. and a voltage of 3 kV / mm for 20 min. Then, under the conditions of a bias magnetic field of 500Oe, an alternating magnetic field of 1Oe, and an alternating magnetic field frequency of 1kHz, the magnetoelectric conversion...

Embodiment 3

[0040] The preparation method of the magnetoelectric composite material of the present embodiment is: the composition is Pb(Ti 0.35 Zr 0.65 )O 3 The piezoelectric ceramics were processed into thin slices with a size of 10×10×0.6 mm. After cleaning, a layer of 0.1 μm Pt conductive electrodes were sputtered on both sides by magnetron sputtering, and wires were welded to the electrodes on both sides. Then, the piezoelectric substrate with the electrode was cleaned, and a layer of 5.0 μm thick (Tb 0.3 Dy 0.68 Ho 0.02 )(Fe 0.90 Zn 0.02 Ti 0.03 al 0.05 ) 1.98 The magnetostrictive film was annealed in situ at 490°C for 10 minutes after the film was deposited. After the preparation of the material, the piezoelectric substrate was polarized along the thickness direction at 100° C. and a voltage of 3 kV / mm for 20 min. Then, under the conditions of a bias magnetic field of 500Oe, an alternating magnetic field of 1Oe, and an alternating magnetic field frequency of 1kHz, the magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com