Connecting material for printing composite ink in polyurethane by using high-speed printer and preparation method for connecting material

A polyurethane technology for printing machines, applied in the field of connecting materials, can solve problems such as low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

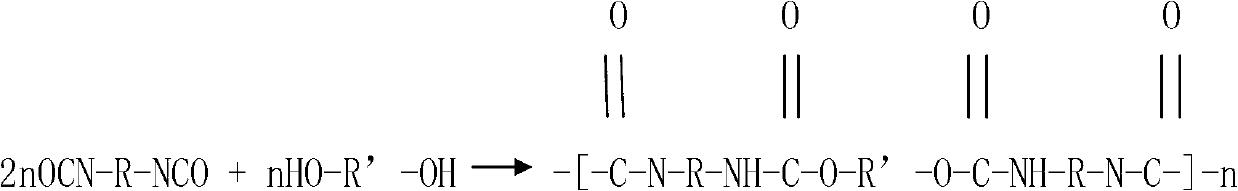

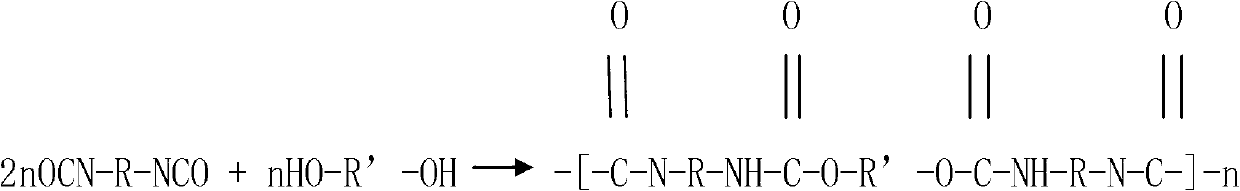

Method used

Image

Examples

Embodiment 1

[0016] The polyurethane ink binder provided in this embodiment contains ethyl acetate, n-propyl acetate, isopropanol, polyester polyol, IPDI, hexamethylenediamine and isophoronediamine, and the parts by weight of each component are respectively 45 parts of ethyl acetate, 7 parts of n-propyl acetate, 18 parts of isopropanol, 22.7 parts of polyester polyol, 5.1 parts of IPDI, 0.9 parts of hexamethylenediamine and 1.3 parts of isophoronediamine. The preparation method of the polyurethane ink binder provided in the present embodiment 1 adopts the following steps:

[0017] 1) Synthesis of polyester polyols. The raw materials used and the consumption amount are as follows: adipic acid, 32 parts by weight; isophthalic acid, 8.4 parts by weight; lauric acid, 18.2 parts by weight; 1.2 propylene glycol, 10.5 parts by weight; 1.4 butanediol, 16.5 parts by weight ; Neopentyl glycol, 14.4 parts by weight;

[0018] a. Esterification, the operation steps are as follows:

[0019] Add raw m...

Embodiment 2

[0036] The difference between the present embodiment and embodiment 1 is that the high-speed printing machine of the present invention uses polyurethane to print the connecting material used for different inks. It is composed of organic solvents and solids with a total weight of 100 kilograms, and the total weight of the organic solvent is 65 kilograms. , 35 kilograms of total weight of solid content; Described solid content comprises polyester polyol, isocyanate and small molecule chain extender, and the weight of described polyester polyol is 72% of the total weight of solid content, isocyanate weight It is 18% of the weight of the solid content, and the weight of the small molecule chain extender is 10% of the weight of the solid content.

Embodiment 3

[0037]The difference between embodiment 3 and embodiment 1 is that the high-speed printing machine of the present invention uses polyurethane to print the connecting material used for different inks. It is composed of organic solvents and solids with a total weight of 100 kilograms, and the total weight of the organic solvent is 70 kilograms. , 30 kilograms of total weight of solid content; Described solid content comprises polyester polyol, isocyanate and small molecule chain extender, and the weight of described polyester polyol is 85% of the total weight of solid content, isocyanate weight 10% of the weight of the solid content, and the weight of the small molecule chain extender is 5% of the weight of the solid content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com