High wear-resistant roller screen roll and build-up welding process

A high wear-resistant and technological technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of low hardness, easy to fall off, high cost, and achieve the effect of strong toughness, high bonding strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

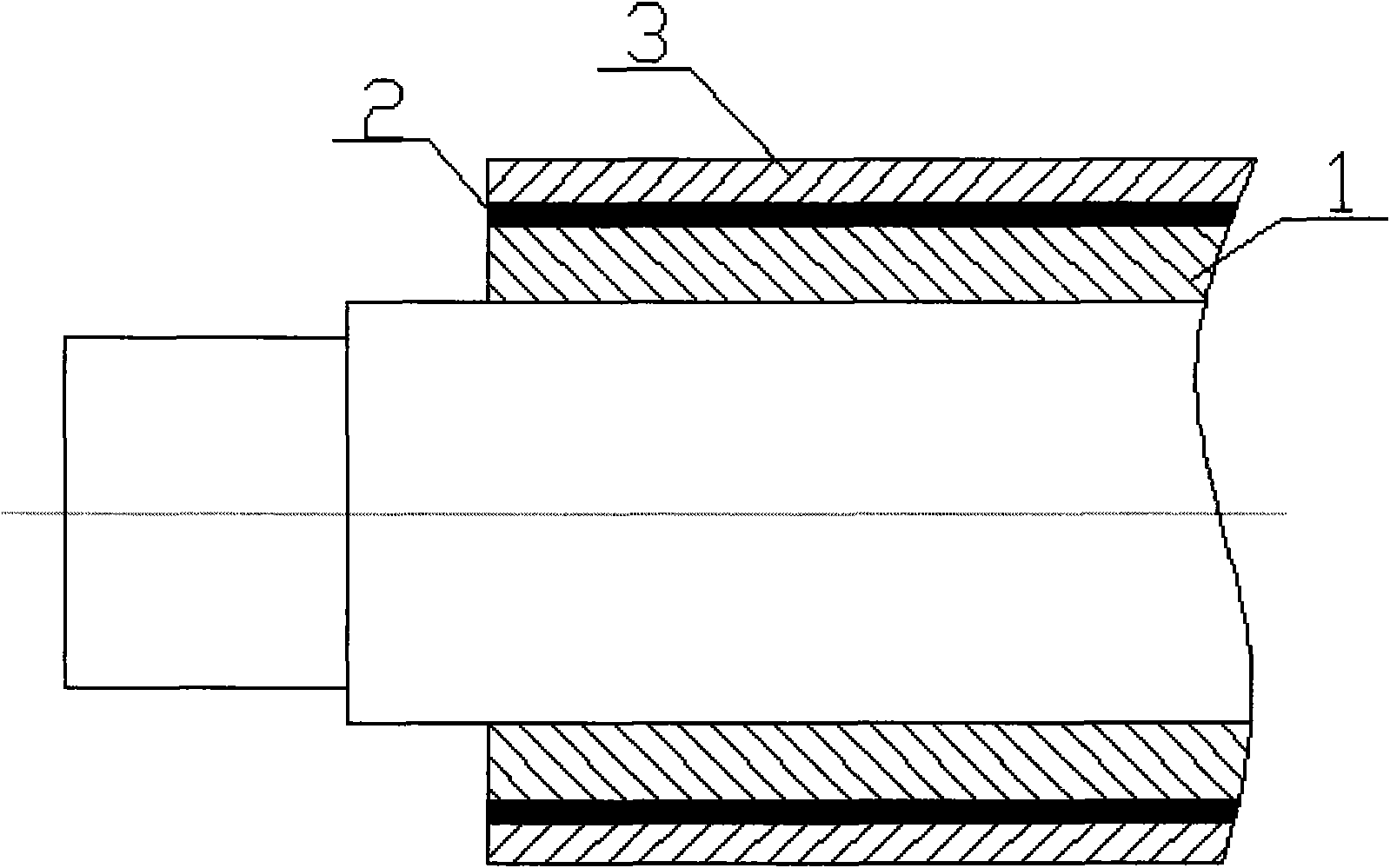

[0019] Such as figure 1 As shown, ordinary carbon steel pipe 1 is used as the substrate of the sieve roll, and the steel pipe is turned before welding. The outer diameter is the finished product size minus 8mm~9mm, and the roughness is not greater than Ra 12.5μm; then transfer to the surfacing process, Before welding, select the appropriate preheating temperature according to the material of the substrate, use submerged arc welding, Φ3.2 flux-cored austenitic stainless steel welding wire, and build up the transition layer 2 first, with a thickness of 2mm to 3mm. Austenitic stainless steel surfacing transition layer is selected, low carbon and high chromium material has low hardness, good weldability and high composite strength. Cracks appear when the wire is used to prepare for the surfacing wear-resistant layer.

[0020] After the surfacing of the transition layer is completed, the wear-resistant layer 3 is surfacing, and the temperature of the transition layer is tested bef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com