Polylactic acid degradable composite material and preparation method thereof

A composite material and polylactic acid technology, applied in the field of polylactic acid degradable composite material and its preparation, can solve the problems of difficult to achieve manufacturing cost and performance, and achieve the effects of fine particles, reduced production cost and strong mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

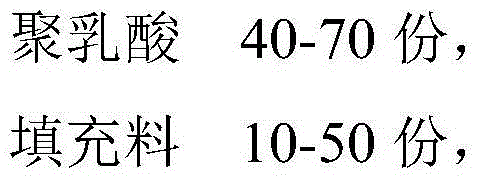

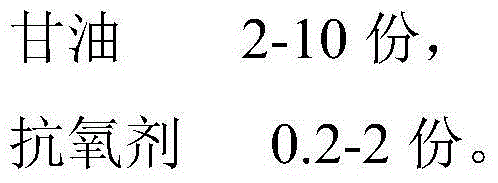

Method used

Image

Examples

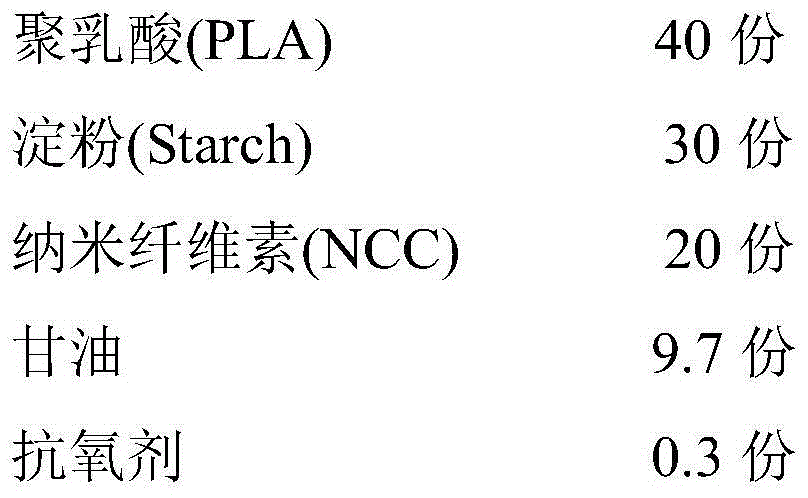

Embodiment 1

[0023] The raw material components are:

[0024]

[0025] Dry the nanocellulose, polylactic acid particles, and starch in a vacuum oven at 70°C for 24 hours, and mix the dried nanocellulose, polylactic acid particles, starch, glycerin, and antioxidant in proportion. Extrude and granulate through a twin-screw extruder. The screw temperatures of the extruder are 130°C, 165°C, 175°C, 180°C, 180°C, and 170°C respectively. The speed of the main screw is controlled at 80r / min, and the speed of the feeding screw is 10r / min, the extruded product is cooled and pelletized to obtain a polylactic acid degradable composite material. The obtained composite material particles were vacuum-dried at 60° C. for 18 hours to obtain the target product.

Embodiment 2

[0027] The raw material components are:

[0028]

[0029]

[0030] Dry the nanocellulose, polylactic acid particles, and starch in a vacuum oven at 70°C for 24 hours, and mix the dried nanocellulose, polylactic acid particles, starch, glycerin, and antioxidant in proportion. Extrude and granulate through a twin-screw extruder, the screw temperature of the extruder is 135°C, 170°C, 175°C, 180°C, 180°C, 170°C, the speed of the main screw is controlled at 80r / min, and the speed of the feeding screw is 10r / min, the extrudate is cooled and pelletized to obtain a polylactic acid degradable composite material. The obtained composite material particles were vacuum-dried at 60° C. for 18 hours to obtain the target product.

Embodiment 3

[0032] The raw material components are:

[0033]

[0034] Dry the nanocellulose, polylactic acid particles, and starch in a vacuum oven at 70°C for 24 hours, and mix the dried nanocellulose, polylactic acid particles, starch, glycerin, and antioxidant in proportion. Extrude and granulate through a twin-screw extruder. The screw temperatures of the extruder are 135°C, 175°C, 180°C, 185°C, 185°C, and 170°C. The speed of the main screw is controlled at 80r / min, and the speed of the feeding screw is 10r / min, the extruded product is cooled and pelletized to obtain a polylactic acid degradable composite material. The obtained composite material particles were vacuum-dried at 60° C. for 18 hours to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com