Water-based gravure composite ink for plastic film and preparation method thereof

A plastic film and gravure technology, which is applied in the field of water-based gravure plastic film composite ink and its preparation, can solve the problems affecting the promotion and popularization of water-based gravure ink, long drying time of water-based gravure ink, and poor wettability of film surface, etc. Solve the problem of VOC emission, good ink leveling and wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

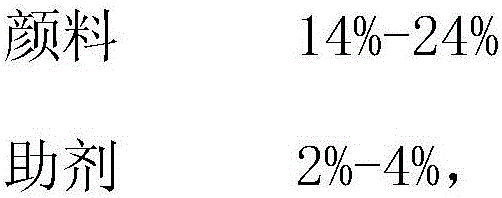

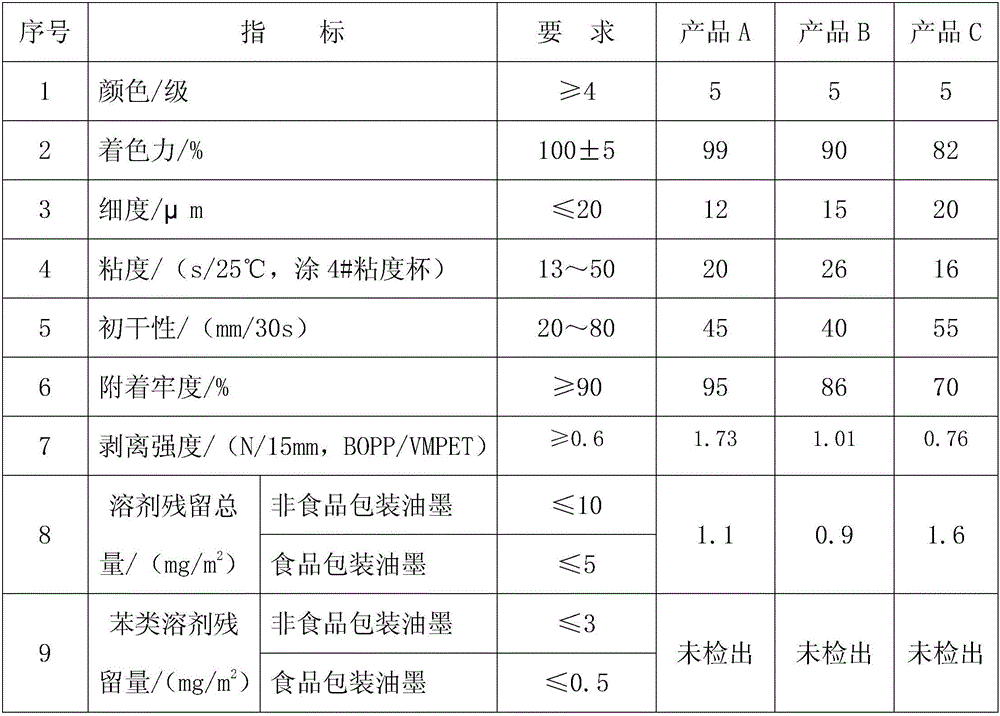

Embodiment 1

[0020] In this example, the polyurethane resin solution was purchased from Anhui Anda Huatai New Material Co., Ltd., the acrylic resin was purchased from Shanghai Hengyao Chemical Co., Ltd., the ternary vinyl chloride resin was purchased from Foshan Gaoming Tongde Chemical Co., Ltd. The reagents were purchased from Dongguan Bocheng Chemical Co., Ltd.

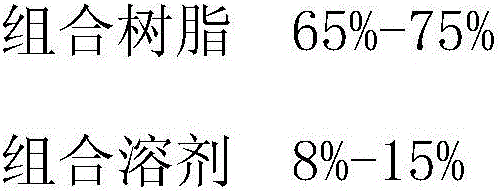

[0021] A water-based gravure plastic film composite ink consists of the following raw materials:

[0022] 40 parts by weight of polyurethane resin, 25 parts by weight of acrylic resin, 5 parts by weight of ternary vinyl chloride resin, 16 parts by weight of monoazo primary yellow pigment, 0.3 parts by weight of dispersant, 1.0 parts by weight of anti-settling agent, 0.6 parts by weight of wear-resistant agent , 0.5 parts by weight of an adhesion promoter, 0.1 parts by weight of a leveling agent and 0.2 parts by weight of a defoamer; 8 parts by weight of deionized water, and 3.3 parts by weight of 95% ethanol.

[0023] Mix the a...

Embodiment 2

[0027] A water-based gravure plastic film composite ink consists of the following raw materials:

[0028] 35 parts by weight of polyurethane resin, 30 parts by weight of acrylic resin, 10 parts by weight of ternary vinyl chloride resin, 16 parts by weight of monoazo primary color yellow pigment, 0.3 parts by weight of gas dispersant, 1.0 parts by weight of anti-settling agent, 0.6 parts by weight of wear-resistant agent 0.5 parts by weight of adhesion promoter, 0.1 parts by weight of leveling agent and 0.2 parts by weight of defoamer; 8 parts by weight of deionized water, 3.3 parts by weight of 95% ethanol;

[0029] The preparation method was the same as in Example 1 to obtain "Product B".

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com