Meshing type composite plate vacuum rolling preparation method

A technology of vacuum rolling and clad plate, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of complex process and limited degree, reduce interface oxidation, increase contact area, and increase composite strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

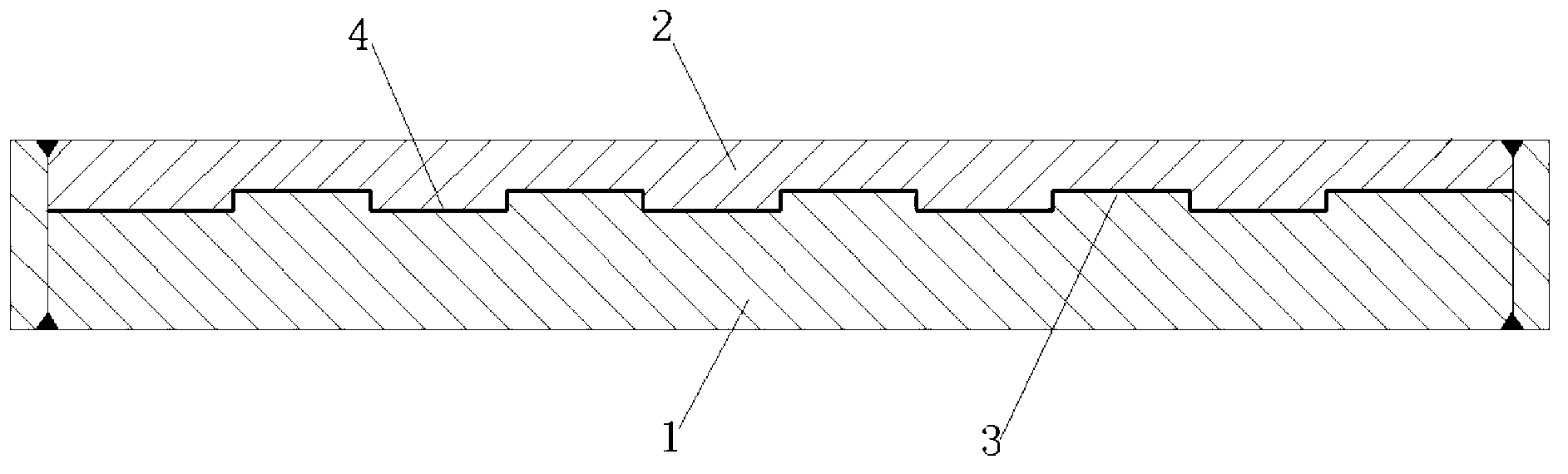

[0044] Such as figure 1 Shown: This method is used to prepare stainless steel-carbon steel single-sided composite panels.

[0045] 1. Slab processing: select one carbon steel plate and one stainless steel plate with a size of 1200mm long × 600mm wide. The carbon steel plate is made of Q235 plate with a thickness of 60mm, and the stainless steel plate is made of 304 stainless steel with a thickness of 10mm. Along the length direction, mutually matching rectangular protrusions are processed on one surface of the carbon steel plate and the stainless steel plate respectively, the number of rectangular protrusions on a single metal slab is 4, the rectangular protrusions are continuously distributed, and the height of the rectangular protrusions is It is 4mm and its width is 100mm. After the processing is completed, clean the processing surface to remove all oil stains; stack the processing surfaces (ie composite surfaces) of the two metal slabs relative to each other, so that the r...

Embodiment 2

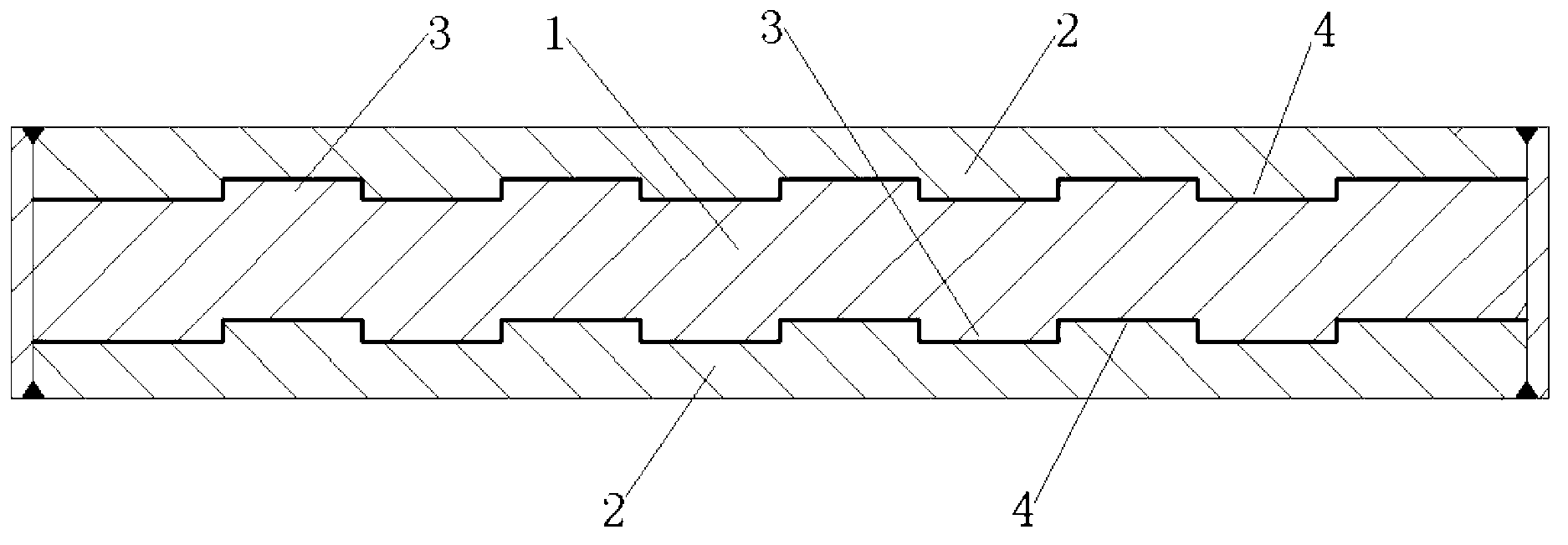

[0052] Such as figure 2 Shown: This method is used to prepare stainless steel-carbon steel double-sided composite panels.

[0053] 1. Slab processing: Select carbon steel plate and stainless steel plate with a length of 1200mm×width 600mm respectively. The carbon steel plate adopts Q345 plate with a thickness of 60mm and the quantity is 1 piece. The stainless steel plate adopts 304 stainless steel with a thickness of 10mm and the quantity is 2 pieces. Along the length direction, mutually matching rectangular protrusions are processed on two surfaces of the carbon steel plate and one surface of the stainless steel plate respectively. The number of rectangular protrusions on a single metal slab is 5, and the rectangular protrusions are continuously distributed. The height of the protrusion is 3mm, and its width is 80mm. After processing, clean the processing surface to remove all oil stains; stack the slabs in the order of stainless steel plate, carbon steel plate, and stainle...

Embodiment 3

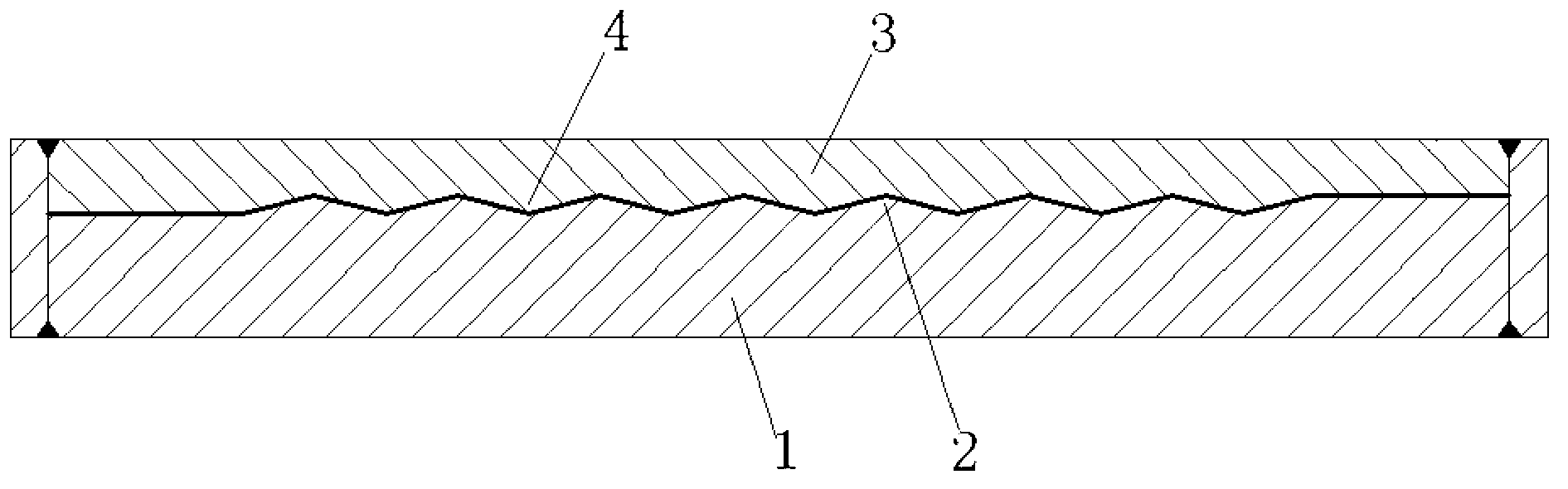

[0060] Such as figure 1 Shown: This method is used to prepare carbon steel extra-thick plates.

[0061] 1. Slab processing: Select two carbon steel slabs with a size of 1000mm long x 600mm wide x 200mm thick. The carbon steel plate is Q345. Along the length direction of the slab, process triangular protrusions on the surface of two carbon steel slabs respectively, the number of triangular protrusions is 8, the triangular protrusions are continuously distributed, the height of the triangular protrusions is 20mm, and its width is 100mm. , cleaning the processing surface, removing all oil stains; stacking the processing surfaces of two carbon steel slabs relative to each other, so that the triangular protrusions on the two carbon steel slabs are in a meshing state, thereby obtaining a composite slab.

[0062] 2. Sealing and welding: The composite slabs are welded with equal-length sealing and welding plates to seal the space between adjacent metal slabs, and the sealing and weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com