Composite conductive material of graphene film and metal nanometer structure and preparation method thereof

A metal nanostructure, graphene thin film technology, applied in metal/alloy conductors, nanotechnology for materials and surface science, nanotechnology, etc., can solve difficult to meet the requirements of practical applications, high resistance of conductive materials, affect conduction performance and other issues, to achieve the effects of good light transmittance, excellent electrical conductivity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 adopts CVD method to synthesize graphene thin film on copper nanostructure, comprises the following basic steps:

[0049] (1) Copper nanoparticles (about 100nm in particle diameter) are uploaded to the CVD system prepared by graphene;

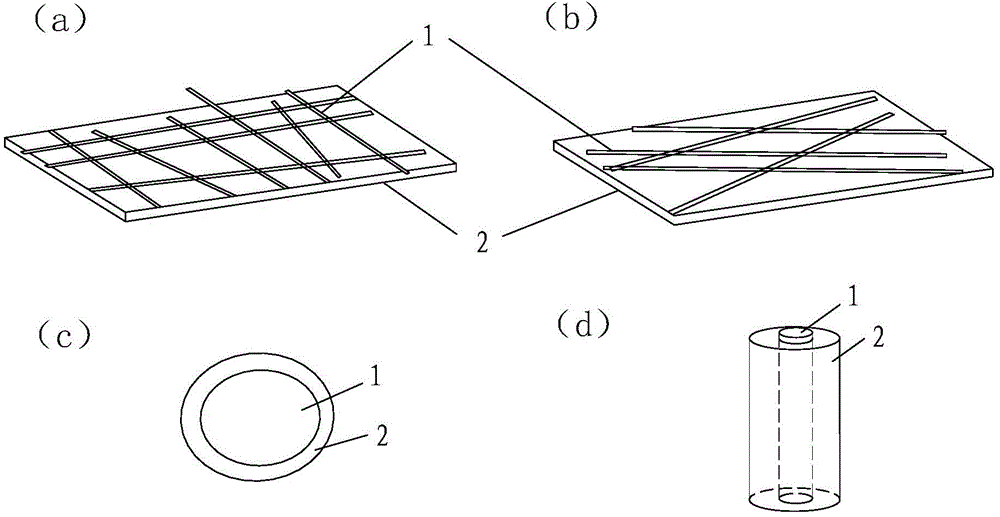

[0050] (2) Using methane gaseous carbon source (H 2 / CH 4 The flow ratio of the graphene film is 20:1) to synthesize a graphene film on the surface of copper nanoparticles, the synthesis temperature is 1030°C, and the synthesis time is 2 hours. Conductive material with core-shell structure, its structure diagram is as follows figure 1 (c) shown.

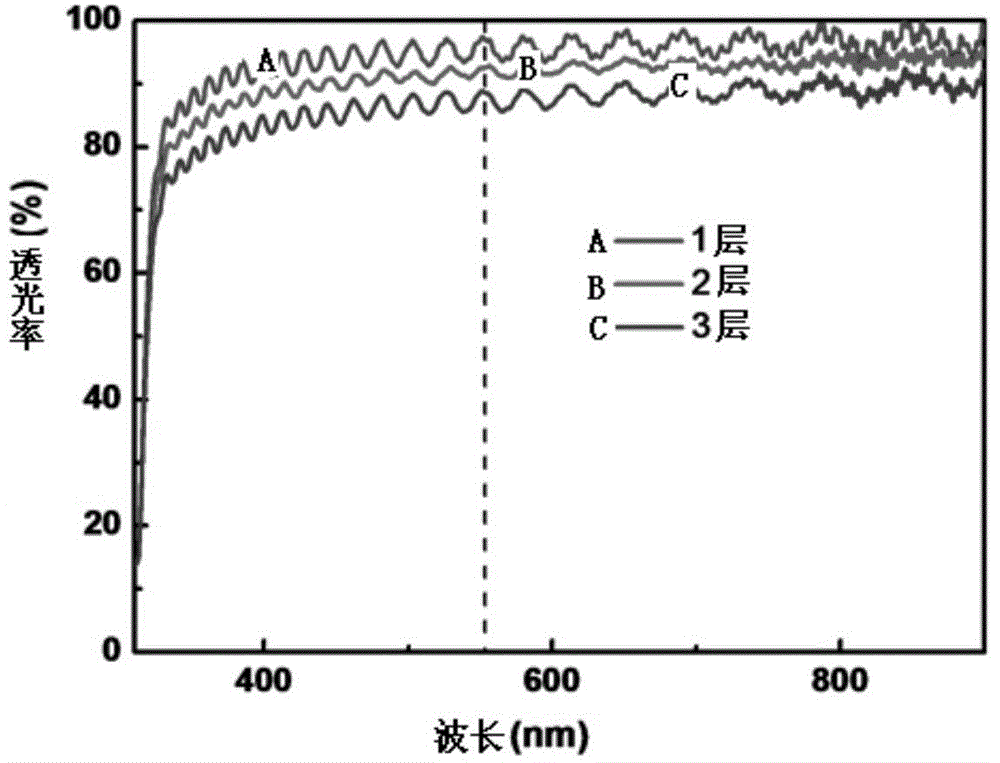

[0051] The graphene film that embodiment 1 is synthesized is the graphene of 4 layers, also can adjust the experimental parameters such as the time that prepares graphene film, the flow rate of methane and adjust the number of layers of synthetic graphene film according to actual needs. The carbon source for synthesizing graphene film can be gaseous, liquid or even solid carbon...

Embodiment 2

[0052] Embodiment 2 adopts carbon segregation method to synthesize graphene thin film on nickel-copper alloy nanostructure, comprises the following basic steps:

[0053] (1) Ni-Cu nanowires (about 50nm in diameter and about 5000nm in length) are buried in carbon powder with a purity of 85%;

[0054] (2) Treat at a temperature of about 1000°C for 20 hours;

[0055] (3) be cooled to room temperature, carbon atom segregation forms graphene film (thickness about 30 layers of graphene) on the surface of nickel-copper alloy like this, forms nickel-copper: the core-shell structure of graphene film, its structural diagram is as follows figure 1 (d) shown.

[0056] The metal nanostructure that embodiment 2 adopts is nickel-copper alloy nanowire, but also can select other metal nanostructure, as silver, gold, platinum, nickel, aluminum, magnesium, tungsten, ruthenium etc. and their alloy composition, its size scale , shape, etc. can be determined according to actual needs. The graphe...

Embodiment 3

[0057] Embodiment 3 adopts solid-state carbon source method to synthesize graphene thin film on nickel foil, comprises the following basic steps:

[0058] (1) Upload the nickel foil (25 μm in thickness) to the graphene preparation system;

[0059] (2) Prepare a carbon film of about 10nm on the nickel foil, and then in Ar / H 2 Under the atmosphere of the carbon film, the nickel foil deposited with the carbon film was heat-treated for about 40 minutes, and then cooled to room temperature to prepare a graphene film (the number of layers is 3 layers of graphene);

[0060] (3) adopt spin coating method to prepare polymethacrylate (PMMA) support layer on the graphene film of nickel / graphene film, the thickness of support layer is about 500nm;

[0061] (4) Micro-nano processing is carried out to the nickel foil of PMMA / graphene film / nickel, makes nickel foil form the nanostructure of net shape, the nickel band width in the nickel mesh structure is 300nm, thereby prepares PMMA / graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com