Method for germanium-silicon epitaxy of high germanium concentration

A germanium-silicon epitaxy and germanium concentration technology, applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., can solve the problems of reduced production capacity, limited and high concentration of germanium, and achieve the effect of stable pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

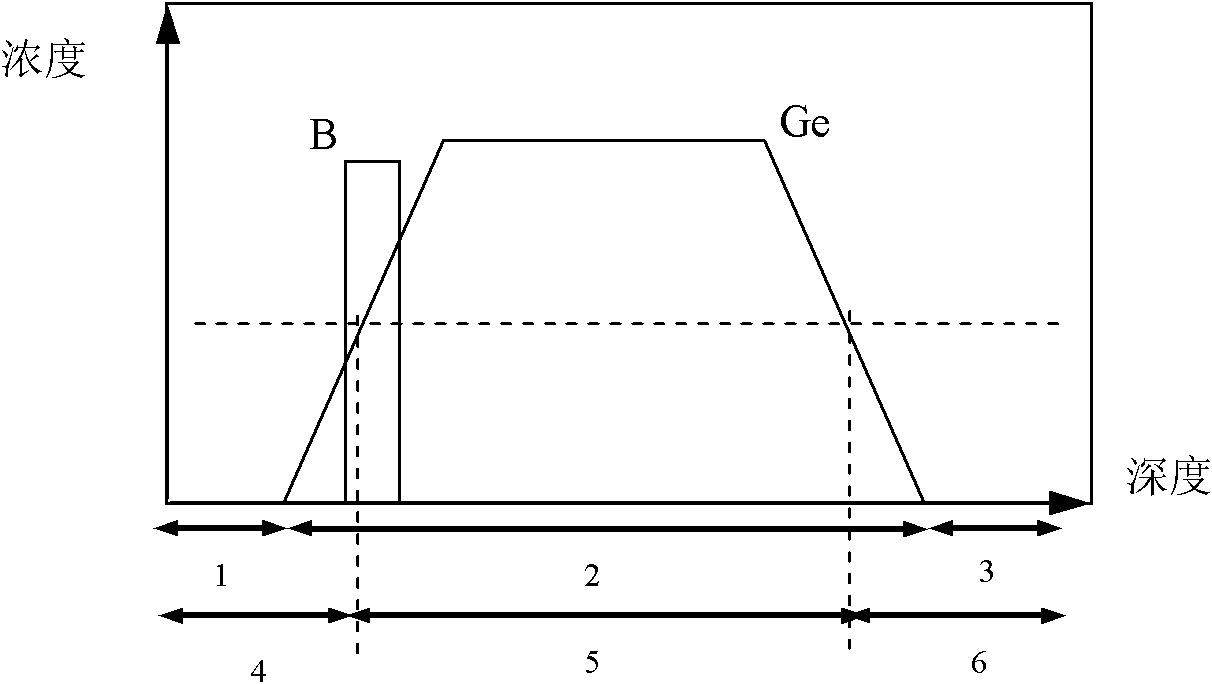

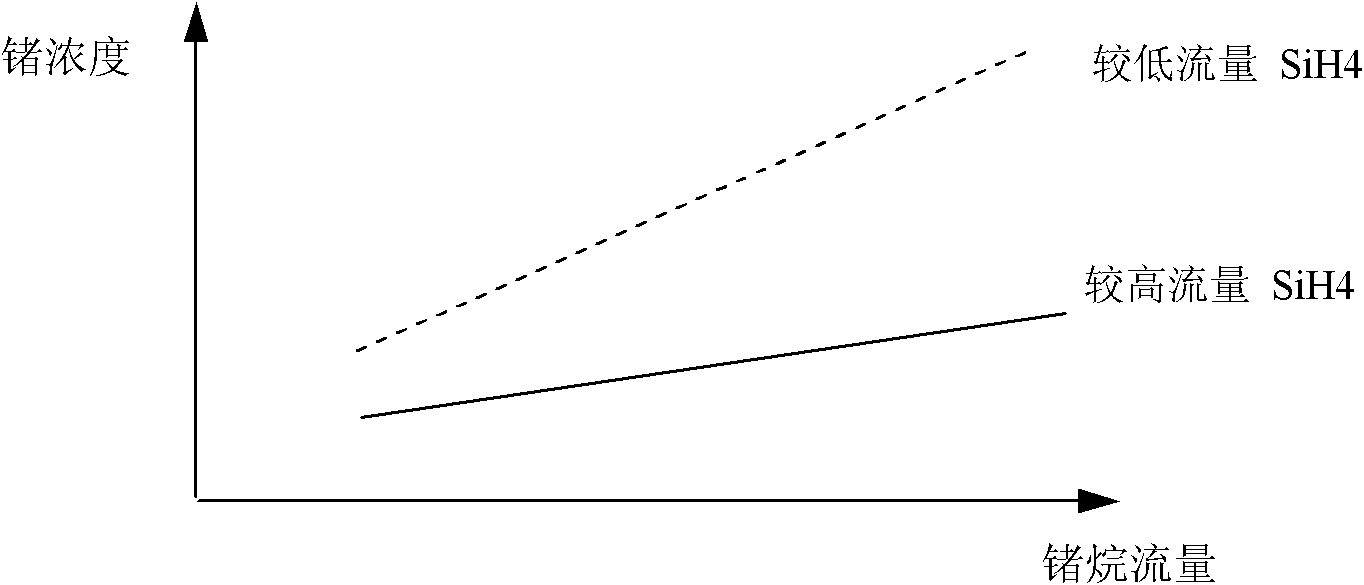

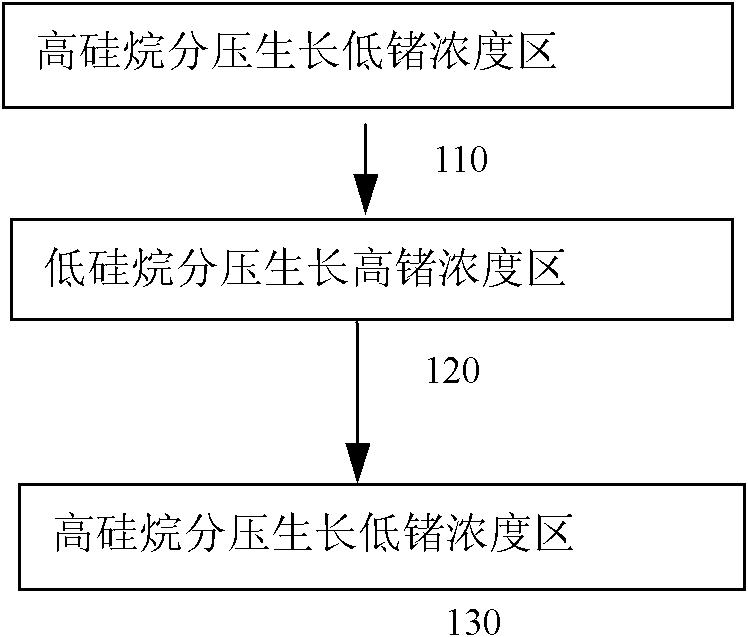

[0022] The invention discloses a silicon-germanium epitaxy method with high germanium concentration. When silane and germane gases are fed, the content of germanium (Ge) in the silicon-germanium epitaxy can be increased if the percentage of silane and germane is reduced. Such as figure 2 The schematic diagram of germanium doping concentration of different silicon source / germanium source ratios of the present invention is shown, at the same germanium source flow rate, as the silicon source flow rate decreases ( figure 2 Medium and low flow SiH 4 ), the concentration of germanium has a relatively large increase; at the same time, the concentration of germanium also increases with the increase of germanium flow rate, but the increase of germane flow rate has less influence on the increase of germanium concentration than the decrease of silane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com