Method for processing spindly shaft by utilizing 17-4PH stainless steel

A stainless steel, slender shaft technology, which is applied in the field of stainless steel processing slender shafts, can solve the problems of acceleration, impossibility, poor deformation ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

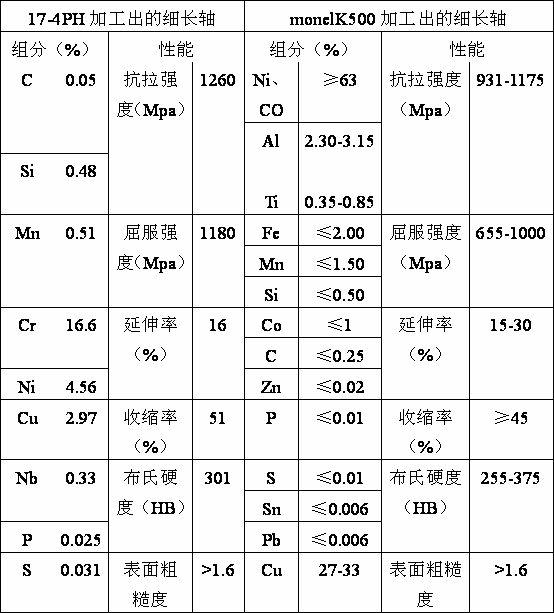

Embodiment 1

[0022] Using 17-4PH stainless steel to process φ The method of mm major axis includes the following steps:

[0023] (1) Weigh 148kg of industrial pure iron, FeNb70: 1kg, Si-A: 1kg, JMn97: 1kg, JCr99-A: 33kg, electrolytic Ni: 8kg, electrolytic Cu: 8kg, and place the ingredients in a vacuum melting furnace Vacuum melting, the melting temperature is 1600°C, and the melting time is 1.5 hours;

[0024] (2) Pouring the melting liquid after vacuum melting into a mold with a cylindrical cavity in the vacuum chamber, and pouring into a cylindrical ingot of φ200mm;

[0025] (3) Water-cool the poured ingot to room temperature;

[0026] (4) Turning the surface of the ingot;

[0027] (5) After forging the ingot after turning into several sections of φ60mm ingot, put it into water to quench;

[0028] (6) Hot-roll each section of the ingot, the hot-rolling temperature is 900°C, the rolling power is 300 kilowatts, and rolled into a φ32mm ingot, and the hot-rolled ingot is quenched in wat...

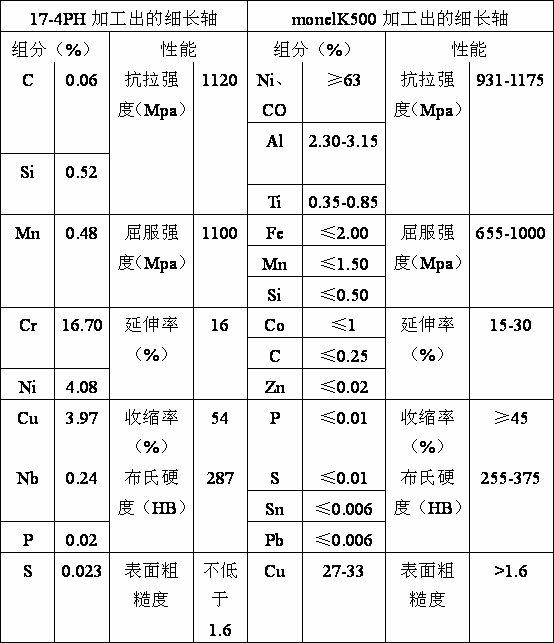

Embodiment 2

[0039] Using 17-4PH stainless steel to process φ The method of mm major axis includes the following steps:

[0040] (1) Weigh 149kg of industrial pure iron, FeNb70: 1kg, Si-A: 1kg, JMn97: 1kg, JCr99-A: 33kg, electrolytic Ni: 9kg, electrolytic Cu: 6kg, and place the ingredients in a vacuum melting furnace Vacuum melting, the melting temperature is 1520°C, and the melting time is 1 hour;

[0041] (2) Pouring the melting liquid after vacuum melting into a mold with a cylindrical cavity in the vacuum chamber, and pouring into a cylindrical ingot of φ200mm;

[0042] (3) Water-cool the poured ingot to room temperature;

[0043] (4) Turning the surface of the ingot;

[0044] (5) After forging the ingot after turning into several sections of φ60mm ingot, put it into water to quench;

[0045] (6) Hot-roll each section of the ingot, the hot-rolling temperature is 950°C, the rolling power is 300 kilowatts, and rolled into a φ27mm ingot, and the hot-rolled ingot is quenched in water;...

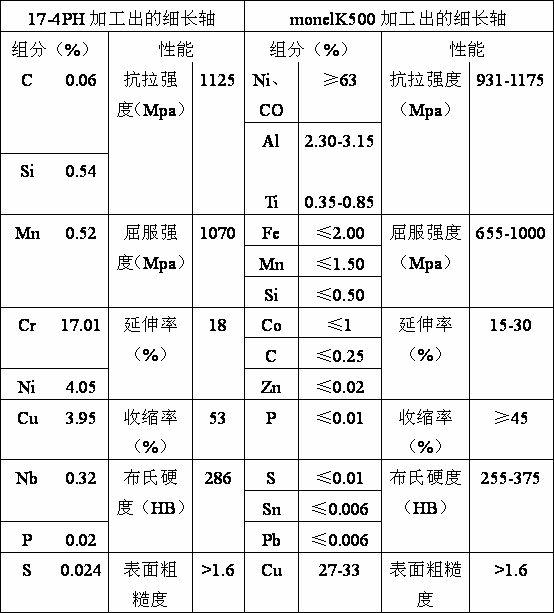

Embodiment 3

[0056] Using 17-4PH stainless steel to process φ The method of mm major axis includes the following steps:

[0057](1) Weigh 148kg of industrial pure iron, FeNb70: 1kg, Si-A: 1kg, JMn97: 1kg, JCr99-A: 33kg, electrolytic Ni: 8kg, electrolytic Cu: 8kg, and place the ingredients in a vacuum melting furnace Vacuum melting, the melting temperature is 1560°C, and the melting time is 2 hours;

[0058] (2) Pouring the melting liquid after vacuum melting into a mold with a cylindrical cavity in the vacuum chamber, and pouring into a cylindrical ingot of φ200mm;

[0059] (3) Water-cool the poured ingot to room temperature;

[0060] (4) Turning the surface of the ingot;

[0061] (5) After forging the ingot after turning into several sections of φ60mm ingot, put it into water to quench;

[0062] (6) Hot-roll each section of the ingot, the hot-rolling temperature is 925°C, the rolling power is 300 kilowatts, and rolled into a φ24mm ingot, and the hot-rolled ingot is quenched in water;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com