Recovery method of fiber reinforced composite material

A composite material, fiber reinforced technology, applied in the field of fiber reinforced composite material degradation and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

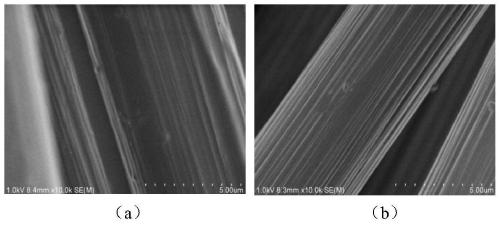

[0034] The leftover material of the fiber reinforced composite material is prepared from fiber and epoxy resin, wherein the fiber is carbon fiber; the epoxy resin is glycidyl ether epoxy resin. The leftovers of fiber-reinforced composite materials were crushed into uniform fragments with a particle size of 3 cm using a commercially available crusher before degradation.

[0035] Add 1 gram of carbon fiber composite material fragments, 0.5 gram of formic acid as an organic catalyst and 15 grams of toluene as an organic solvent in a three-necked flask, start the stirrer to stir, heat the water bath to 110 ° C for 1 hour, and then slowly drop 10 grams of 5% Aqueous hydrogen peroxide solution, degradation reaction for 12 hours, cooling after the end of the reaction, filtering solid-liquid separation to obtain solid intermediate product carbon fiber and liquid intermediate product degradation liquid; the solid intermediate product obtained was washed with water, dried and separated t...

Embodiment 2

[0037] The leftover material of the fiber reinforced composite material is prepared from fiber and epoxy resin, wherein the fiber is glass fiber; the epoxy resin is glycidyl ester epoxy resin. The leftovers of fiber-reinforced composite materials were crushed into uniform fragments with a particle size of 5 cm using a commercially available crusher before degradation.

[0038] Add 1 gram of carbon fiber composite material fragments and 15.5 grams of formic acid to the three-necked flask, which has the dual functions of organic catalyst and organic solvent, start the stirrer to stir, heat the water bath to 100 ° C for 1 hour, and then slowly drop 10 grams of 40% formic acid Aqueous hydrogen peroxide solution, degraded reaction for 10 hours, cooled after the reaction, filtered solid-liquid separation, and obtained solid intermediate product carbon fiber and liquid intermediate product degradation liquid; the obtained solid intermediate product was washed with water, dried and sep...

Embodiment 3

[0040] The leftover material of the fiber reinforced composite material is prepared from fiber and epoxy resin, wherein the fiber is aramid fiber, and the epoxy resin is glycidyl amine epoxy resin. The leftovers of fiber-reinforced composite materials were crushed into uniform fragments with a particle size of 4 cm using a commercially available crusher before degradation.

[0041]Add 1 gram of carbon fiber composite material fragments and 15.5 grams of acetic acid to the three-necked flask, which has the dual functions of an organic catalyst and an organic solvent, start the stirrer to stir, heat the water bath to 115 ° C for 1 hour, and then slowly drop 10 grams of 30% acetic acid Aqueous hydrogen peroxide solution, degradation reaction for 6 hours, cooling after the reaction, filtering solid-liquid separation, obtaining solid intermediate product carbon fiber and liquid intermediate product degradation liquid; washing the obtained solid intermediate product with water, separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com