Degradable isocyanate and application thereof

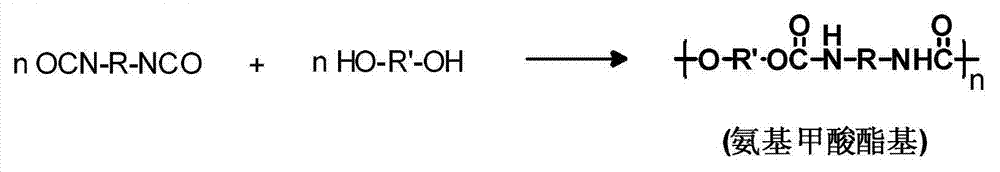

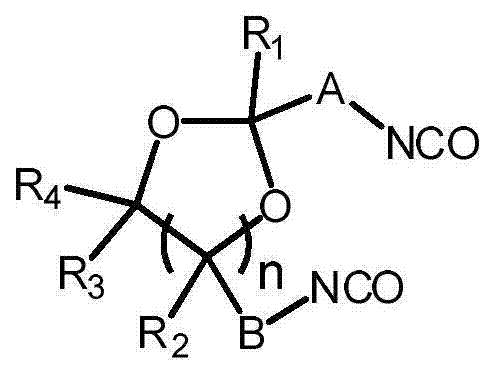

An isocyanate and aromatic technology, used in the synthesis of resins and degradable curing agents, can solve the problems of recycled fiber shortening, performance degradation, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

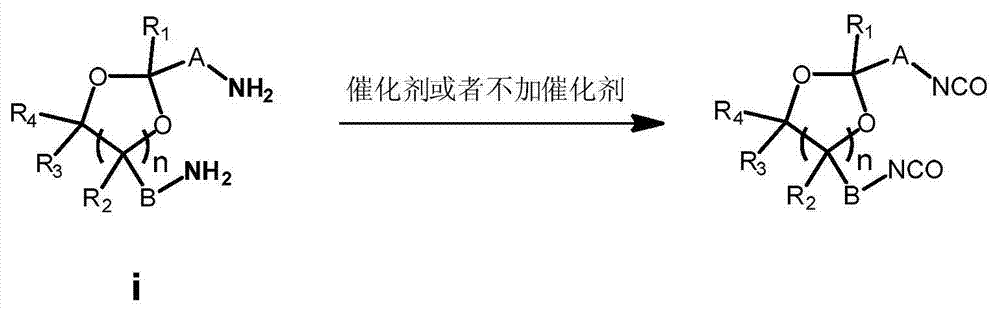

Method used

Image

Examples

Embodiment 1

[0165] Embodiment 1: the synthesis of isocyanate I

[0166]

[0167] At 0°C, add 23 grams of bis(4-aminophenol)methane and 200 milliliters of dioxane dropwise into a mixed solution of 29.6 grams of triphosgene and 300 milliliters of toluene, control the temperature below 5°C, and the addition ends Afterwards, the temperature was raised to reflux for 4 hours, the reaction was completed, the solvent was concentrated under reduced pressure, 500 ml of petroleum ether was added to the residue, stirred vigorously, filtered, dried, and the organic phase was concentrated to obtain 15 g of white solid, yield: 53.2%. 1 H-NMR (CDCl 3 ,400M): 5.65(2H,s),7.02(8H,S).

Embodiment 2

[0168] Embodiment 2: the synthesis of isocyanate I

[0169] At room temperature, add 23 grams of bis(4-aminophenol) methane and 450 milliliters of ethyl acetate dropwise into a mixed solution of 29.6 grams of triphosgene and 150 milliliters of ethyl acetate, and control the temperature below 30°C. , heated and refluxed overnight, the reaction was completed, the solvent was concentrated under reduced pressure, 500ml of petroleum ether was added to the residue, and vigorously stirred. Filter, dry, and concentrate the organic phase to obtain 18 g of white solid, yield: 63.8%.

Embodiment 3

[0170] Embodiment 3: the synthesis of isocyanate I

[0171] At room temperature, a mixed solution of 2.30 g of bis(4-aminophenol)methane and 20 ml of dichloromethane was added dropwise to a mixed solution of 5.92 g of triphosgene and 40 ml of dichloromethane. After the addition was complete, 6 ml of triphosgene was added dropwise. A mixed solution of ethylamine and 20 ml of dichloromethane. During the dropwise addition, the temperature gradually increased to reflux. After the dropwise addition was completed, stirring was continued at room temperature for 30 minutes. After the reaction was completed, the solvent was concentrated under reduced pressure, 300ml petroleum ether was added to the residue, vigorously stirred, dried, and the organic phase was concentrated to obtain 15 grams of white solid, yield: 40.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com