Method for cleanly transferring single layer graphene by using PMMA

A single-layer graphene and graphene technology, applied in the direction of single-layer graphene, graphene, chemical instruments and methods, etc., can solve the problems of unstable growth, easy curling, incomplete transfer graphene method, etc., and achieve roughness Low, reduce the force, show the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: utilize the method for PMMA to cleanly transfer single-layer graphene in the present embodiment to be accomplished through the following steps:

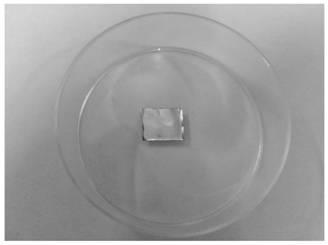

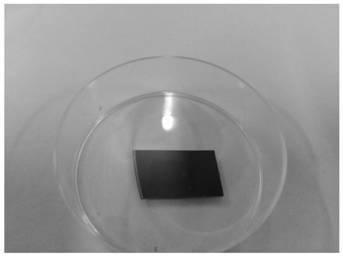

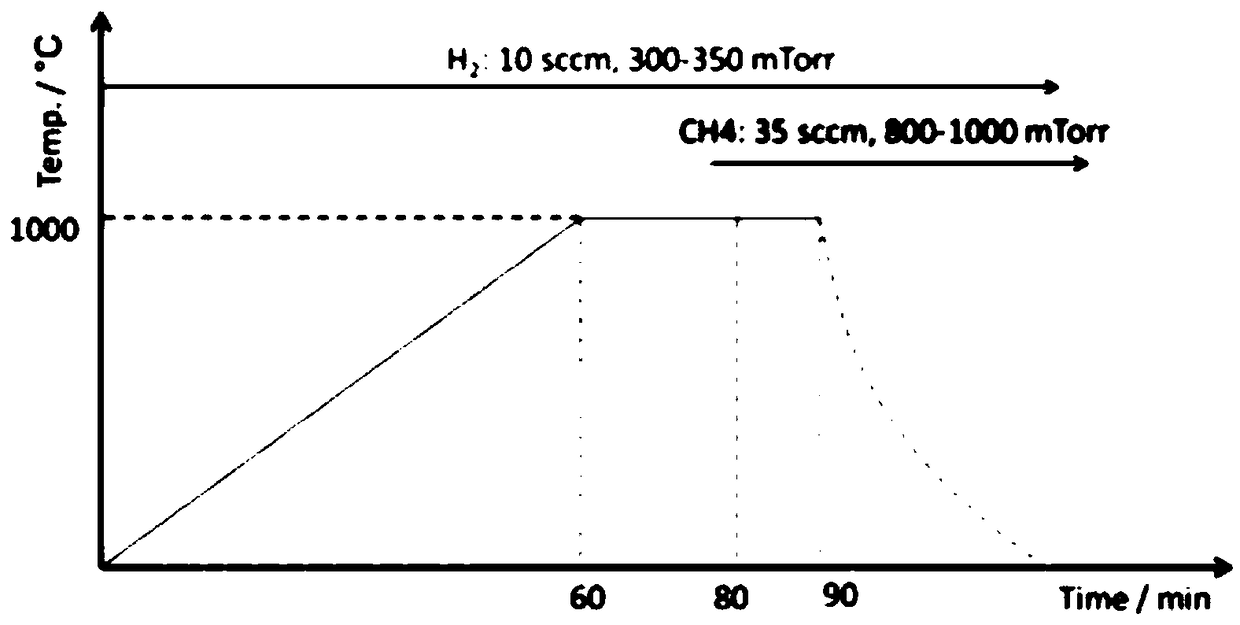

[0041] Step 1, using CVD to grow single-layer graphene on the copper foil substrate;

[0042] Step 2, stick the copper foil with single-layer graphene on the quartz plate with adhesive tape, then spin coat PMMA glue on the graphene surface on the copper foil substrate with 2500rpm, spin coat 100s to obtain the PMMA glue layer thickness is about 200nm, then Put it on a heating plate and heat at 160°C for 2 minutes to solidify the PMMA glue on the graphene surface, and then cut the edge to expose the graphene; the PMMA glue can be prepared in the following way: use anisole as a solvent and add PMMA powder to prepare into a solution with a concentration of 55mg / mL, and stirred evenly at 70°C until the color of the solution changed from milky white to transparent;

[0043] Step 3. Float the copper foil on the surfac...

Embodiment 2

[0053] Embodiment 2: the method utilizing PMMA to cleanly transfer single-layer graphene is accomplished through the following steps in the present embodiment:

[0054] Step 1, using CVD to grow single-layer graphene on the copper foil substrate;

[0055] Step 2, stick the copper foil with single-layer graphene on the quartz plate with adhesive tape, then spin coat PMMA glue on the graphene surface on the copper foil substrate with 3500rpm, spin coat 60s to obtain the PMMA glue layer thickness is about 100nm, then Put it on a heating plate and heat it at 200°C for 1 min to solidify the PMMA glue on the graphene surface, and then cut the edge to expose the graphene; the PMMA glue can be prepared in the following way: use anisole as a solvent and add PMMA powder to prepare into a solution with a concentration of 50mg / mL, and stir evenly at 75°C until the color of the solution changes from milky white to transparent;

[0056] Step 3. Float the copper foil on the surface of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com