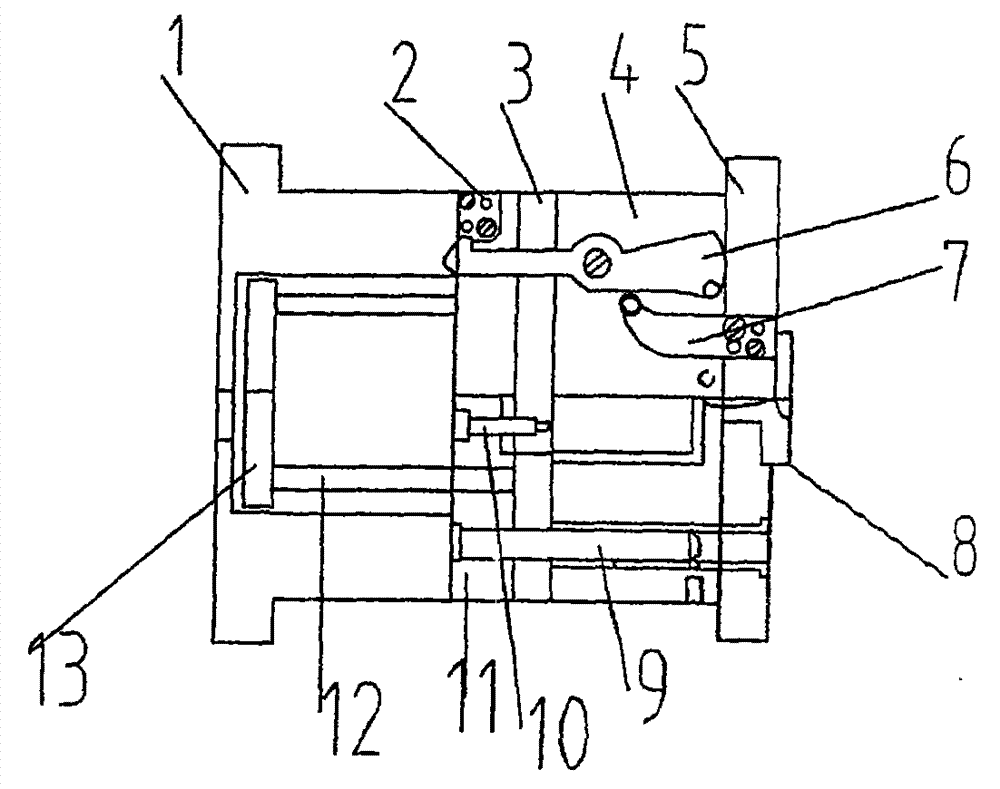

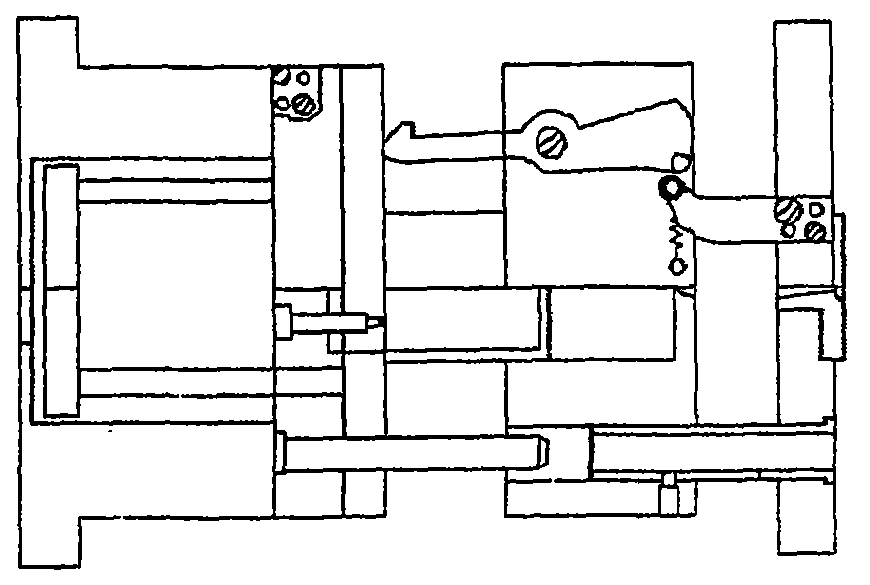

Metal pressure casting die swing hook dual-division swage die mechanism

A die-casting mold and metal technology, which is applied in the field of metal die-casting mold pendulum hook double-parting mold mechanism, can solve the problems of material thickness at the junction of the gate and the casting, difficulty in cutting, automatic gate cut-off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The picture shows the metal die-casting mold pendulum hook double parting mold mechanism. The point of this model is: to use the pull hook and the pendulum hook installed on the outer surface of the mold base to open the two parting surfaces when the mold is opened to complete the automatic The purpose of cutting the gate, the first parting is for the casting to be pulled out of the fixed mold cavity smoothly, so as to achieve the purpose of cutting off the remaining material of the gate by the cutter installed in the mold. The second parting is the purpose of using the opening surface to escape from the casting. The mold is guided by four sets of guide pillars and guide sleeves. In order to ensure the accuracy of mold guidance, the mounting holes of the guide pillars of the fixed formwork, the mounting holes of the guide sleeves on the supporting plate and the fixed plate of the movable mold are processed together. When the cutter cuts off the remaining material at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com