Table component assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]In order that those skilled in the art can further understand the present invention, a description will be described in the following in details. However, these descriptions and the appended drawings are only used to cause those skilled in the art to understand the objects, features, and characteristics of the present invention, but not to be used to confine the scope and spirit of the present invention defined in the appended claims.

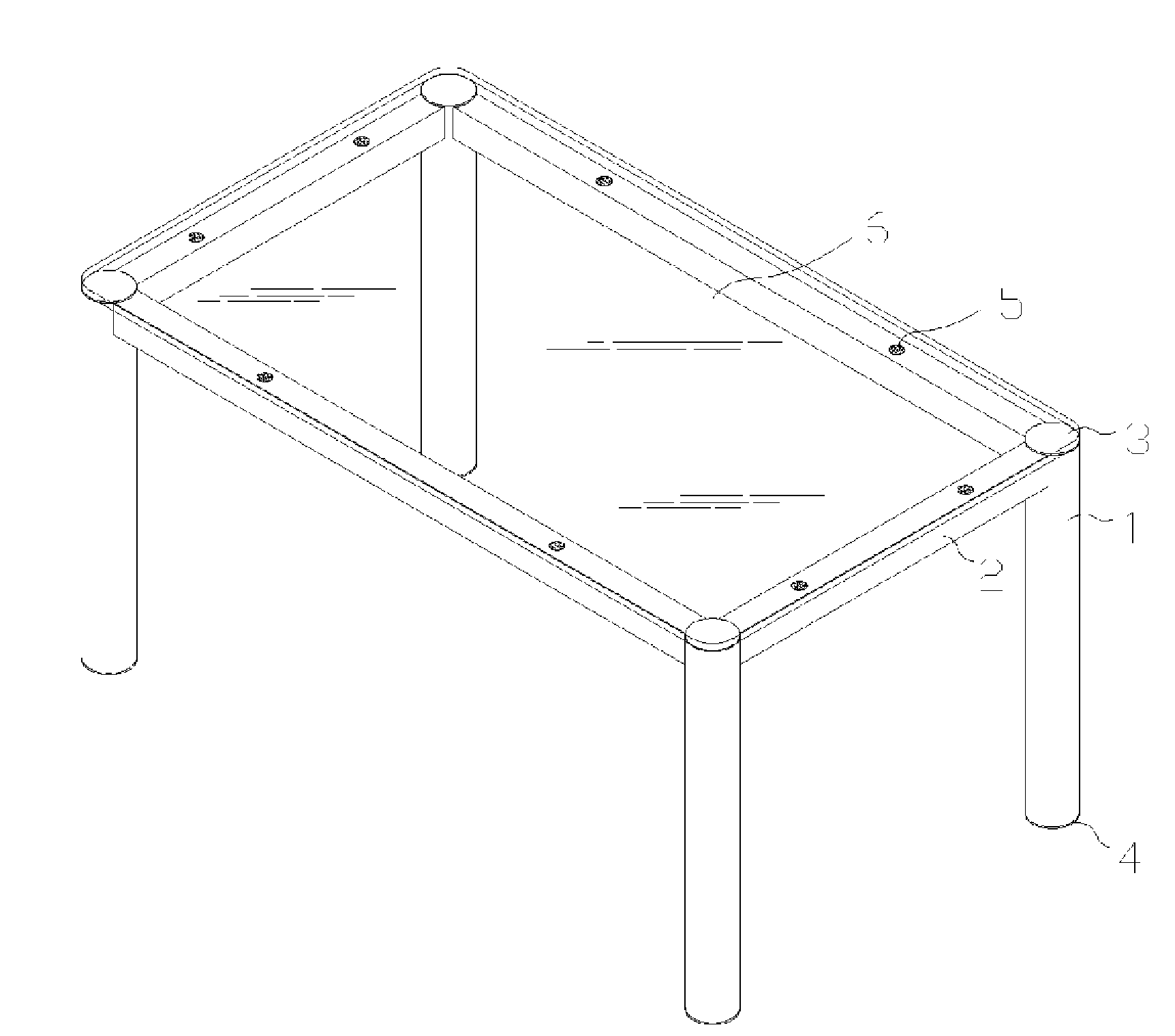

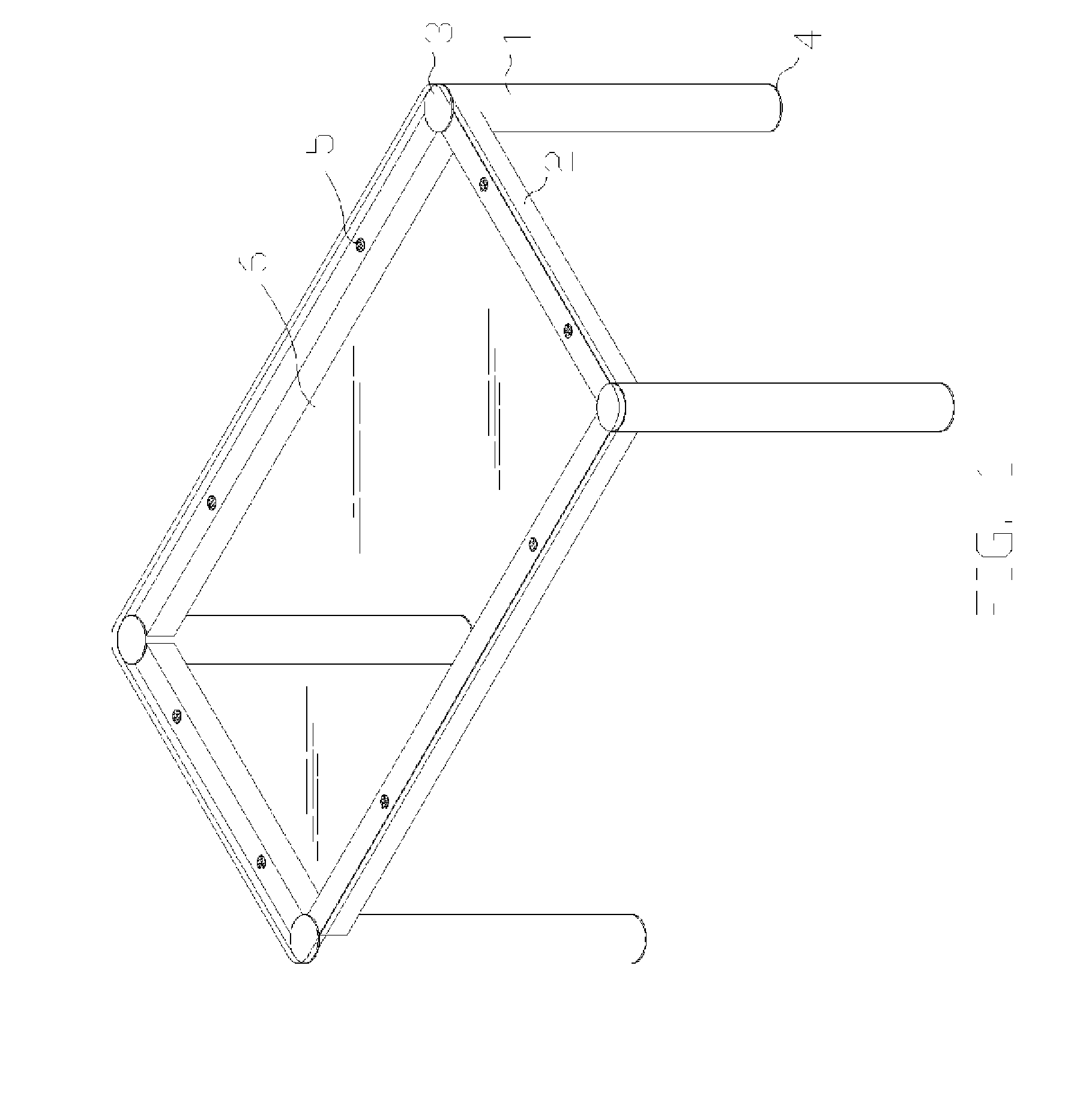

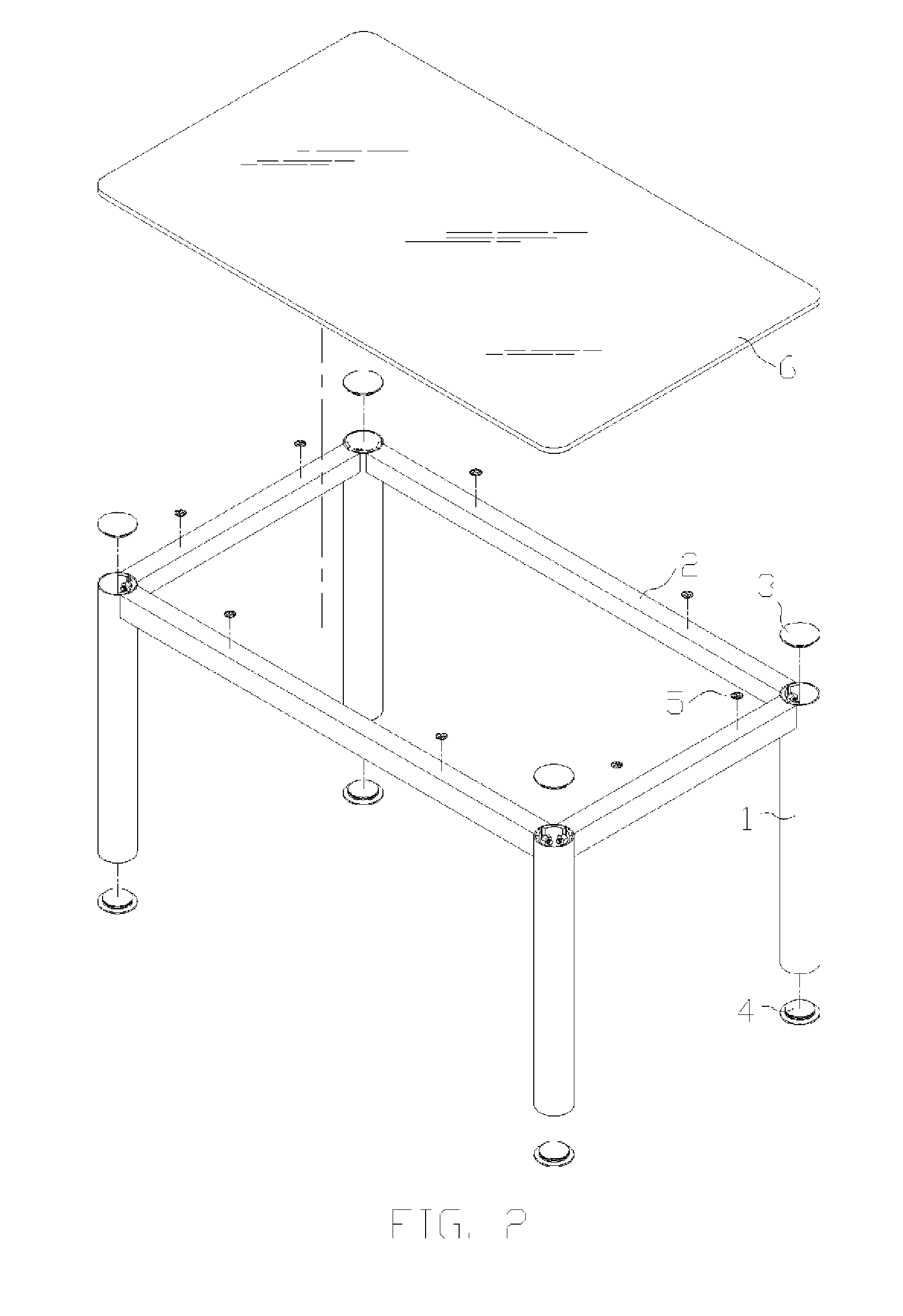

[0022]Referring to FIG. 1, a table main body is assembled by four leg21 with round tube shapes and four beams 2. A plurality of slide stop pads 5 are placed suitably on four table beams so as to provide enough friction force for a glass plate 6. The glass plate 6 as a tabletop is free from arbitrarily movement.

[0023]Referring to FIG. 2, a table leg cover 3 is covered on the leg 1 for a purpose of improving table appearance. Besides, a table leg pad 4 is installed on the bottom of the leg 1 so that the table leg pad 4 can not only prevent from tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com