Polyethersulfone antistatic anticorrosive paint, and preparation method and application thereof

An anti-corrosion coating and anti-static technology, which is applied in the direction of anti-corrosion coatings, conductive coatings, coatings, etc., can solve the problems of difficult application of anti-static coatings, and achieve the effects of controllable coating thickness, simple preparation method, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

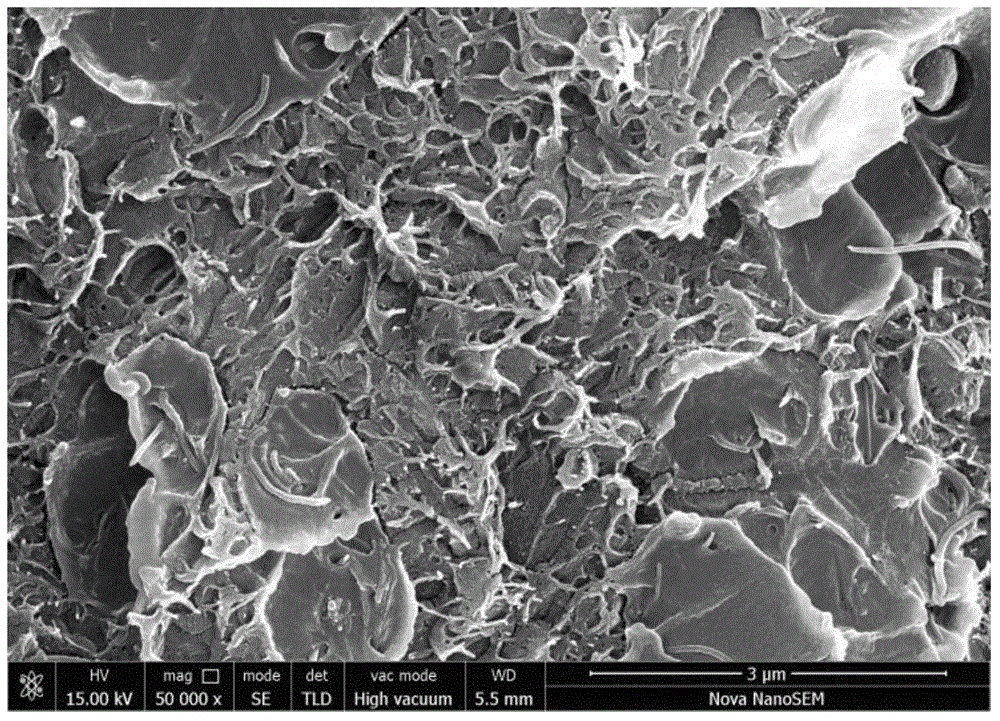

Embodiment 1

[0041] 1) 80g of thermoplastic polyethersulfone resin with a logarithmic specific viscosity of 0.35, 30g of polytetrafluoroethylene resin, 1.5g of dispersible carbon nanotubes (can be CF-0, the content of carbon nanotubes is 1.35g), 75g of toluene , 20g butanone, 75g N, N-dimethylacetamide and 110g N-methylpyrrolidone were mixed, stirred for 30min at a speed of 600r / min, and then sanded for 6 hours at a speed of 3500r / min with a sand mill, A polyethersulfone antistatic anticorrosion coating is obtained.

[0042] 2) After sandblasting the steel plate, wash it with acetone and ethanol, and dry it in an oven.

[0043] 3) By air spraying, the polyethersulfone anti-static anti-corrosion coating is evenly sprayed on the surface of the steel plate, and the coating is obtained by drying and curing.

[0044] 4) Coating properties are shown in the table below:

[0045]

[0046] The antistatic anticorrosion coating provided by the present embodiment, in 10 3 The conductivity at Hz ...

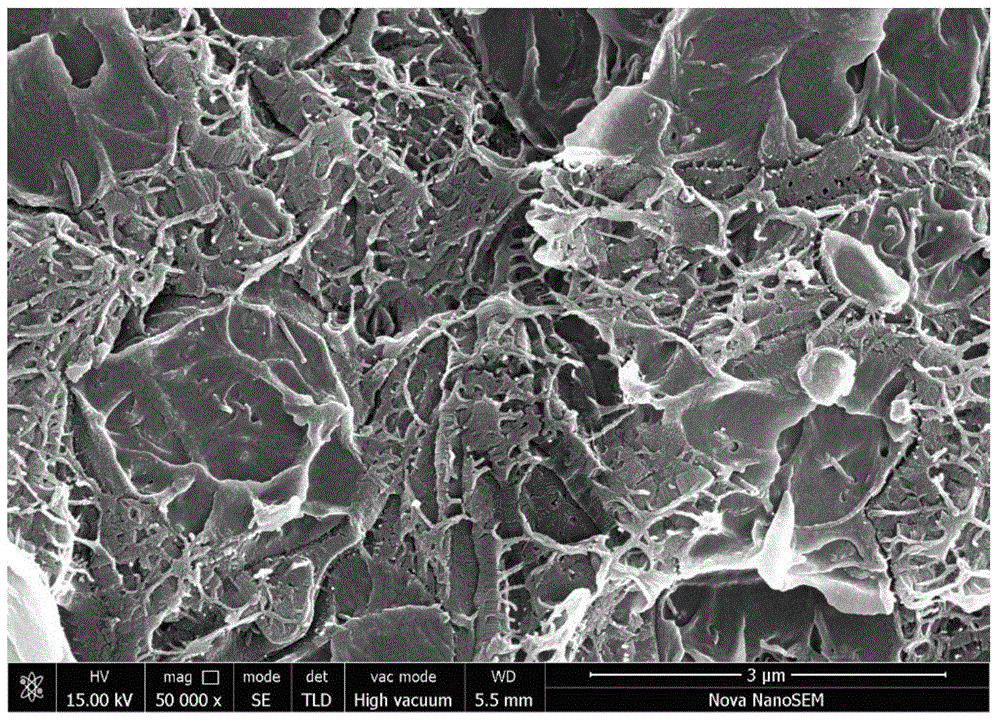

Embodiment 2

[0048] 1) 80g of thermoplastic polyethersulfone resin with a logarithmic specific viscosity of 0.31, 30g of polytetrafluoroethylene resin, 1.5g of dispersible carbon nanotubes (can be CF-0, the content of carbon nanotubes is 1.35g), 75g of toluene , 20g butanone, 75g N, N-dimethylacetamide and 110g N-methylpyrrolidone were mixed, stirred for 30min at a speed of 600r / min, and then sanded for 6 hours at a speed of 5000r / min with a sand mill, A polyethersulfone antistatic anticorrosion coating is obtained.

[0049] 2) After sandblasting the steel plate, wash it with acetone and ethanol, and put it in an oven to dry.

[0050] 3) By air spraying, the polyethersulfone antistatic anticorrosion coating is evenly sprayed on the surface of the steel plate, and the coating is obtained by drying and curing.

[0051] 4) Coating properties are shown in the table below:

[0052]

[0053] The antistatic anticorrosion coating provided by the present embodiment, in 10 3 The conductivity a...

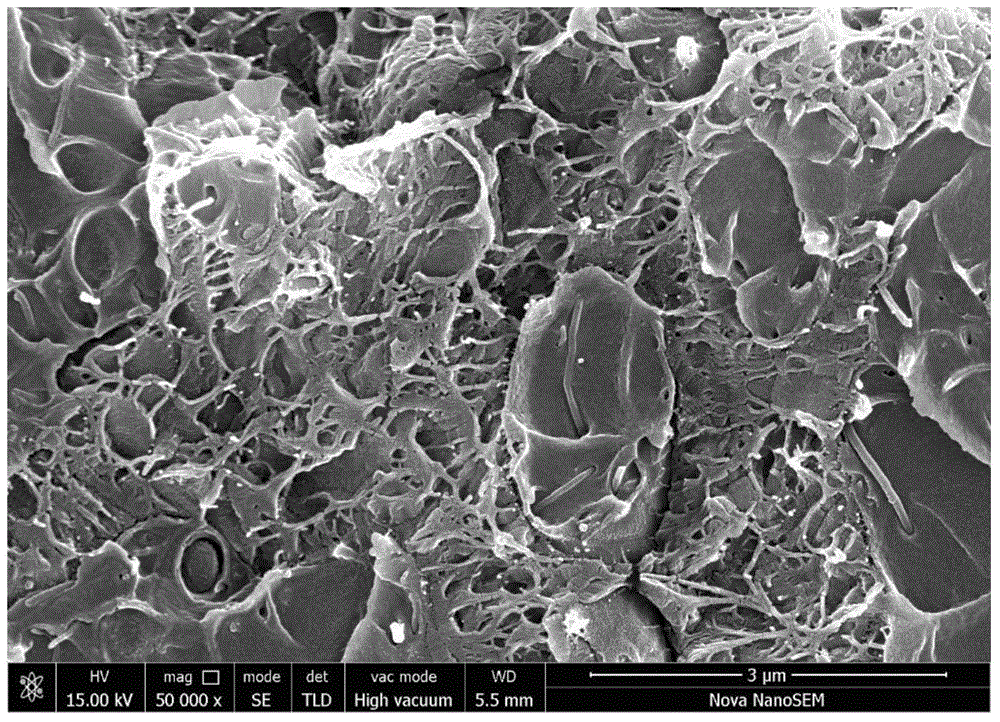

Embodiment 3

[0055] 1) 80g of thermoplastic polyethersulfone resin with a logarithmic specific viscosity of 0.37, 30g of polytetrafluoroethylene resin, 1.5g of dispersible carbon nanotubes (can be CF-0, the content of carbon nanotubes is 1.35g), 75g of toluene , 20g butanone, 75g N, N-dimethylacetamide and 110g N-methylpyrrolidone were mixed, stirred for 30min at a speed of 600r / min, and then sanded for 6 hours at a speed of 3500r / min with a sand mill, A polyethersulfone antistatic anticorrosion coating is obtained.

[0056] 2) After sandblasting the steel plate, wash it with acetone and ethanol, and dry it in an oven.

[0057] 3) By air spraying, the polyethersulfone anti-static anti-corrosion coating is evenly sprayed on the surface of the steel plate, and the coating is obtained after drying and curing

[0058] 4) Coating properties are shown in the table below:

[0059]

[0060] The antistatic anticorrosion coating provided by the present embodiment, in 10 3 The conductivity at H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com