Wear-resistant anti-sticking high-strength coating, composition for forming wear-resistant anti-sticking high-strength coating, and conveying device containing wear-resistant anti-sticking high-strength coating

A composition and high-strength technology, applied in the field of coatings, can solve the problems of poor wear resistance, anti-sticking and strength properties, and achieve the effects of excellent anti-blocking, good wear resistance, and high body strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

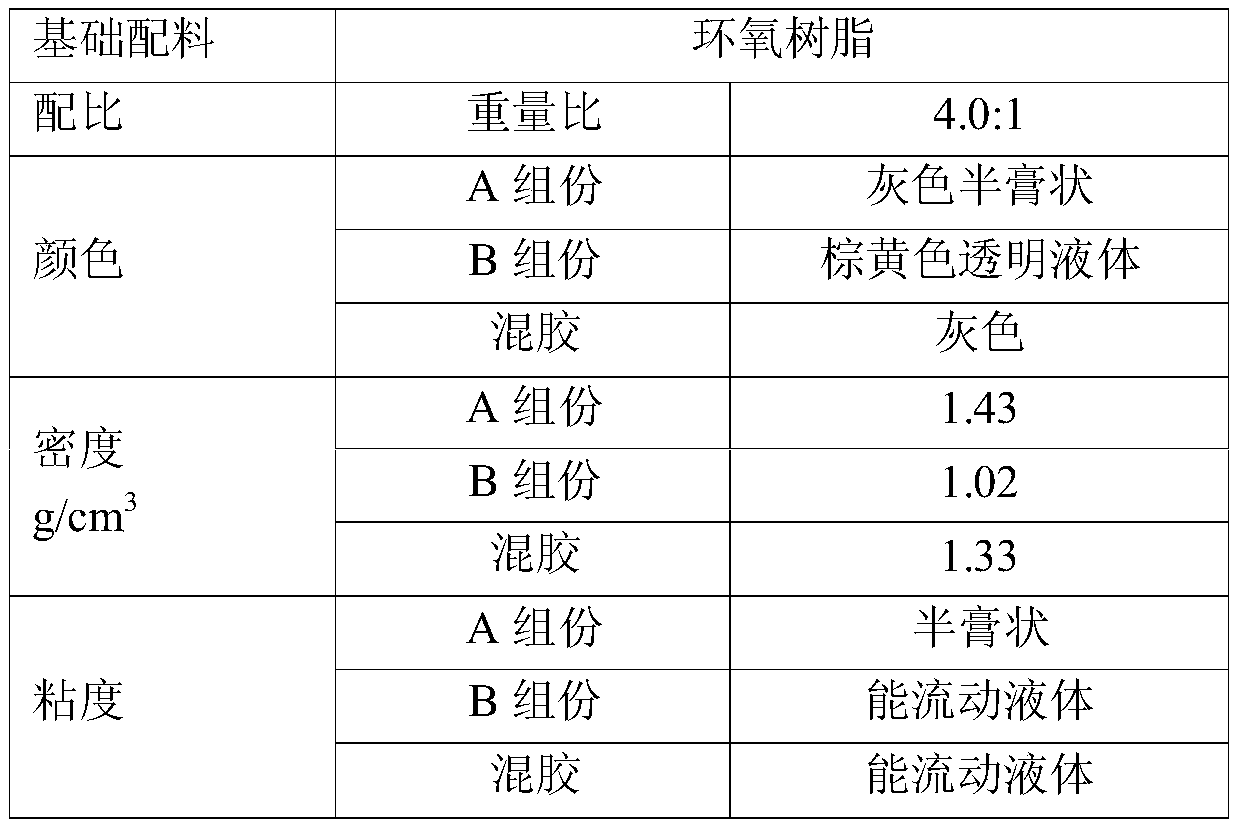

[0043] According to the weight percentage of component A, component A includes: 35% epoxy resin (bisphenol A epoxy), 5% toughening agent (carboxyl-terminated liquid nitrile rubber), 20% micro-nano filler (10nm~50μm hydrophobic silica), 3% hydrophobic additive (silicon modified polyacrylate), 20% wear-resistant filler (100 mesh silicon carbide), 15% hydrophobic filler (polytetrafluoroethylene powder) ) and 2% thixotropic agent (hydrophobic fumed silica).

[0044] According to the weight percentage of component B, component B includes: 95% polymethylene diamine modified amine curing agent and 5% curing accelerator (tris-(dimethylaminomethyl) phenol).

[0045] Component A and component B are mixed in a weight ratio of 4:1 to prepare a wear-resistant, anti-sticking high-strength coating.

Embodiment 2

[0047] According to the weight percentage of component A, component A includes: 39% epoxy resin mixture, 2% toughening agent (polyurethane modified toughening agent), 25% micro-nano filler (hydrophobicity of 10nm~50μm Titanium dioxide), 2% hydrophobic additive (silicon modified polyacrylate), 15% wear-resistant filler (100 mesh ceramic particles), 15% hydrophobic filler (polytetrafluoroethylene powder) and 2% thixotropic agent ( hydrophobic fumed silica). The mixed epoxy resin is composed of 50% bisphenol F epoxy resin and 50% bisphenol A epoxy resin.

[0048] According to the weight percentage of component B, component B includes: 90% of aminonut shell modified amine curing agent and 10% of curing accelerator (benzyl alcohol).

[0049] Component A and component B are mixed in a weight ratio of 4:1 to prepare a wear-resistant, anti-sticking high-strength coating.

Embodiment 3

[0051] The difference from Example 1 is that the epoxy resin is an epoxy resin mixture, and the epoxy resin mixture is 80% bisphenol A epoxy resin and 20% novolac epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com