Anti-adhesion spray coating material used for molten iron tank, preparation method and spray coating method thereof

A technology for molten iron cans and paint spraying is applied in the field of refractory materials, which can solve the problem of high material cost and achieve the effect of good anti-sticking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

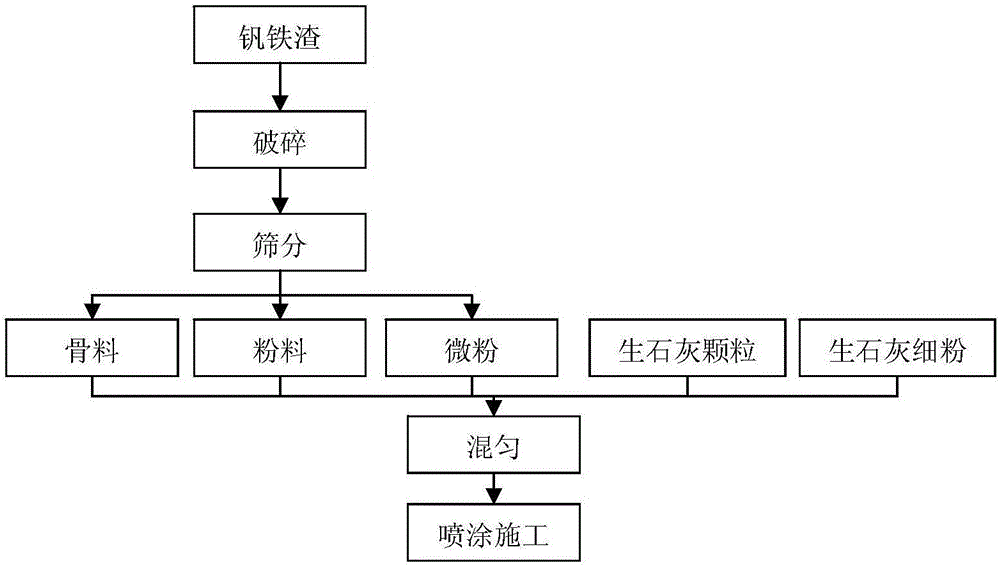

[0025] Embodiment 1 anti-sticking spray paint, such as figure 1 As shown, the specific steps are:

[0026] 1) The aluminum oxide content in the ferrovanadium slag adopted by the aluminothermic method is 65.7%, and the calcium oxide content is 10.6%. The ferrovanadium slag is crushed, ground, and sieved to make an aggregate particle size of 0.5-3mm, and the ferrovanadium slag powder particle size is Less than 0.5mm, the particle size of vanadium iron slag powder is less than 0.045mm.

[0027] 2) Crushing and screening quicklime with a calcium oxide content of 88% to produce quicklime particles with a particle size of 0.5-2 mm and quicklime powder with a particle size of less than 0.2 mm.

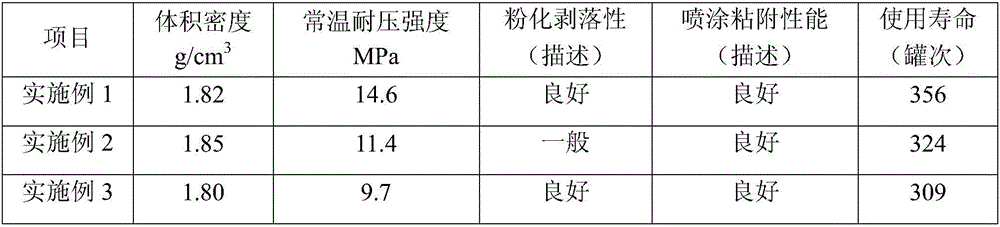

[0028] 3) Weigh 55% of vanadium iron slag aggregate, 20% of powder, 5% of micropowder, 15% of quicklime particles, 5% of quicklime powder, and 0.2% of dispersant (external mix) according to weight percentage; mix the above materials evenly, pack , You can get the anti-adhesive coating produ...

Embodiment 2

[0029] Embodiment 2 anti-sticking spray paint, such as figure 1 As shown, the specific steps are:

[0030] 1) The alumina content in the aluminothermic ferrovanadium slag is 65.7%, and the calcium oxide content is 10.6%. The ferrovanadium slag is crushed, ground and sieved to make an aggregate particle size of 0.5-3mm, and the ferrovanadium slag powder particle size is less than 0.5mm, the particle size of vanadium iron slag powder is less than 0.045mm.

[0031] 2) Crushing and screening quicklime with a calcium oxide content of 88% to produce quicklime particles with a particle size of 0.5-2 mm and quicklime powder with a particle size of less than 0.2 mm.

[0032] 3) Weigh 60% of vanadium-iron slag aggregate, 20% of powder, 5% of micropowder, 10% of quicklime particles, 5% of quicklime powder, and 0.2% of dispersant (external mix) according to weight percentage; mix the above materials evenly, pack , You can get the anti-adhesive coating product.

Embodiment 3

[0033] Embodiment 3 anti-sticking spray paint, such as figure 1 As shown, the specific steps are:

[0034] 1) The alumina content of the vanadium-iron slag adopted by the aluminothermic method is 65.7%, and the calcium oxide content is 10.6%. mm, the particle size of vanadium iron slag powder is less than 0.045mm.

[0035] 2) Crushing and screening quicklime with a calcium oxide content of 88% to produce quicklime particles with a particle size of 0.5-2 mm and quicklime powder with a particle size of less than 0.2 mm.

[0036] 3) Weigh 50% of vanadium iron slag aggregate, 20% of powder, 10% of micropowder, 15% of quicklime particles, 5% of quicklime powder, and 0.5% of dispersant (external mix) according to weight percentage; mix the above materials evenly, pack , You can get the anti-adhesive coating product.

[0037] The above anti-adhesive coating products are packaged in woven bags with plastic film. When in use, pour the dry material into the silo of the spraying machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com