High-temperature self-lubricating material for manufacturing bearings and preparation method thereof

A high-temperature self-lubricating, bearing technology, applied in the field of powder metallurgy, can solve the problems of high consumption of precious non-ferrous metals, serious bearing wear, high energy consumption, etc., to achieve good practicability and economy, high bearing capacity, and low friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

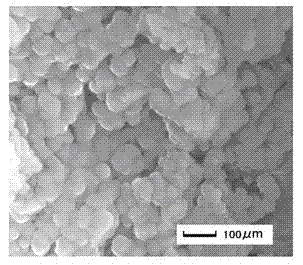

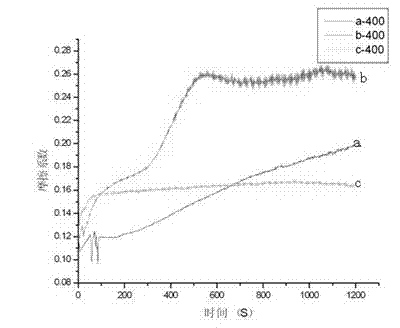

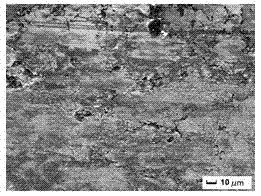

Image

Examples

Embodiment 1

[0023] A preparation method of a high-temperature self-lubricating composite material, the preparation steps are as follows:

[0024] (1) Take 0.3% mica by weight, 5% barium fluoride (Sinopharm Chemical Reagent Co., Ltd., content ≥ 99.0%), 3% graphite (Sinopharm Chemical Reagent Co., Ltd., content ≥ 99.85%), granular degree (≤30um)≥95.0%), 1% molybdenum disulfide (Sinopharm Chemical Reagent Co., Ltd., content ≥98%), 13% copper (300 mesh), 43% alloy powder (10-20%Cr , 8-12%W, 30-40%Ni and the rest of Fe) and 34.7% iron powder, fully mixed on the V-type mixer for 8-10h;

[0025] (2) Add the mixture to the mixture of water and sodium stearate (sodium stearate: ingredients = 3:100, mass ratio; sodium stearate: water = 1:4, mass ratio) and stir evenly. Put the mixed ingredients into the oven and bake for 8-10 hours;

[0026] (3) Then take it out and put it into the mold, control the pressure to 400bar, hold the pressure for 20-30s and press to form;

[0027] (4) Then put the com...

Embodiment 2

[0030] Method is the same as Example 1, except that 1% barium fluoride, 38.7% iron powder.

Embodiment 3

[0032] Method is the same as Example 1, except that 3% barium fluoride, 36.7% iron powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com