Laminated polyester film

A laminated polyester film, polyester film technology, applied in the direction of coating, layered products, synthetic resin layered products, etc., can solve the problems of rising costs and increasing manufacturing processes, and achieve excellent antistatic properties and industrial value high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

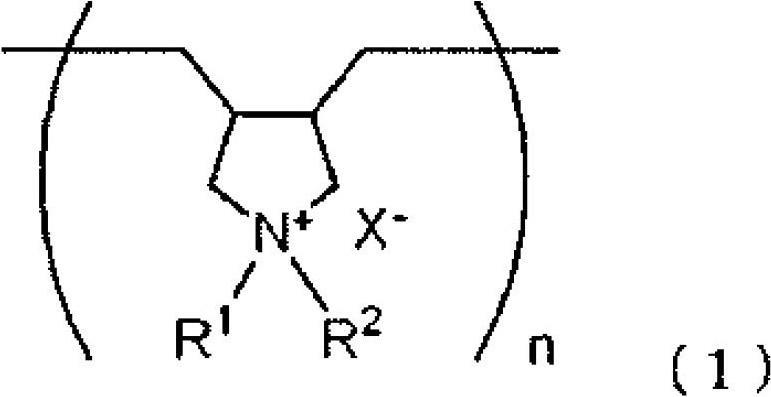

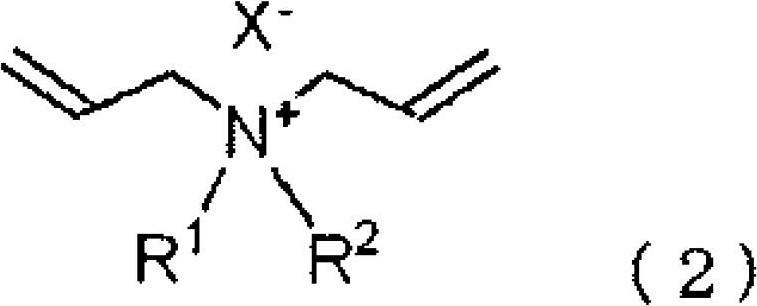

Method used

Image

Examples

manufacture example

[0027] Next, although the production example of the polyester film in this invention is demonstrated concretely, it is not limited to the following production example at all. That is, it is preferable to obtain an unstretched sheet by cooling and solidifying a molten sheet extruded from a die with a cooling roll using the above-mentioned polyester raw material. At this time, in order to improve the planarity of the sheet, it is preferable to increase the adhesion between the sheet and the rotating cooling drum, and it is preferable to use an electrostatic application adhesion method and / or a liquid coating adhesion method. Next, the obtained unstretched sheet is stretched in biaxial directions. At this time, first, the aforementioned unstretched sheet is stretched in one direction by a stretching machine of a roll or tenter type. The stretching temperature is usually 70 to 120°C, preferably 80 to 110°C, and the stretching ratio is usually 2.5 to 7 times, preferably 3.0 to 6 t...

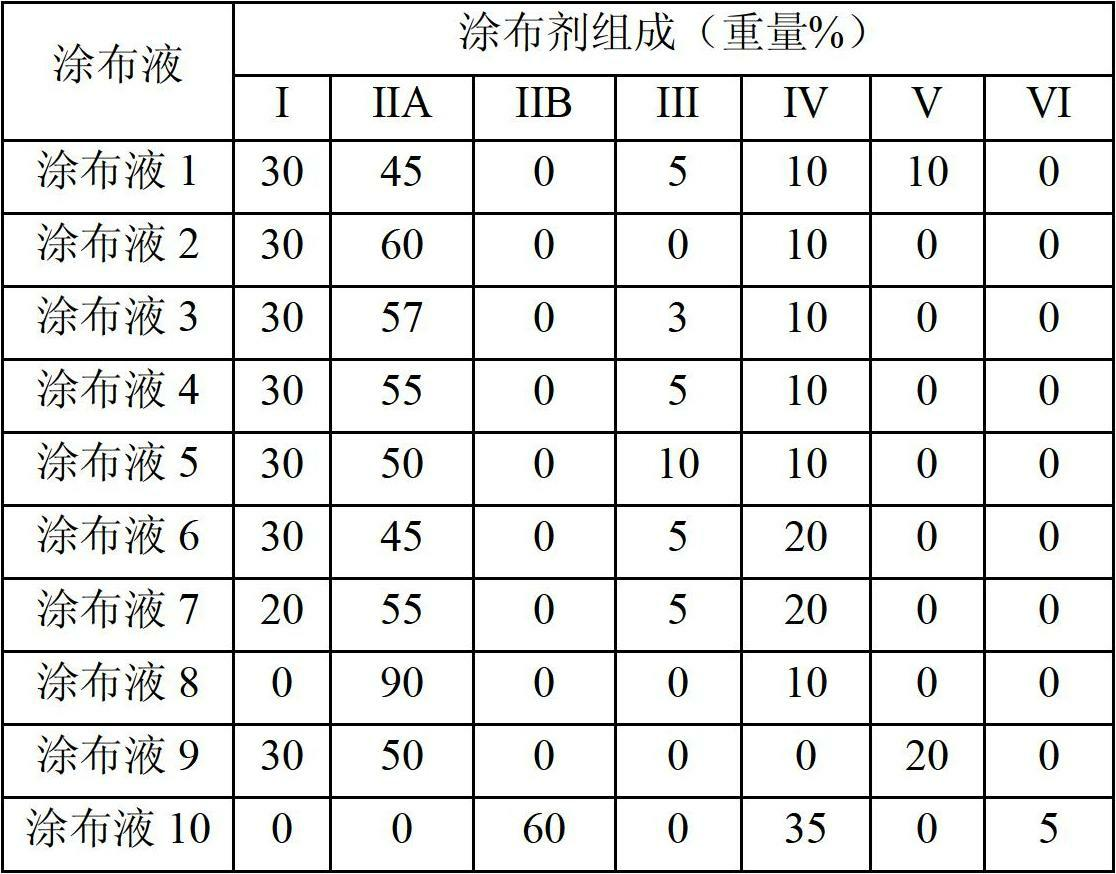

Embodiment 1

[0144] Mix polyester (A), (B), and (C) in proportions of 85%, 5%, and 10% respectively as raw materials for the outermost layer (surface layer), and mix polyester in proportions of 95%, 5%, respectively. The mixed raw materials of esters (A) and (B) are supplied to two extruders as the raw materials for the middle layer, and after being melted at 290°C, two kinds of three layers (surface layer / intermediate layer / surface layer=1:18:1 discharge rate) layer structure co-extruded, cooled and solidified to obtain an unstretched sheet. Next, using the difference in roll rotation speed, the film was stretched 3.4 times in the longitudinal direction at a film temperature of 85°C. After that, one side of the longitudinally stretched film was coated with the coating liquid 1 shown in Table 1 below, and after drying, it was 0.09. g / m 2 , apply the coating liquid 10 on the opposite side, and let it dry to 0.03g / m 2 , introduced into a tenter, stretched 4.0 times at 120° C. in the trans...

Embodiment 2~6

[0147] In Example 1, except having changed the coating agent composition into the coating agent composition shown in Table 1, it manufactured similarly to Example 1, and obtained the polyester film. Table 2 shows the properties of the obtained polyester film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com