Laminated polyester film

A laminated polyester film, polyester film technology, applied in the direction of coatings, layered products, synthetic resin layered products, etc., can solve the problems of increased number of manufacturing processes and cost increases, and achieve excellent anti-adhesive properties and industrial advantages. high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

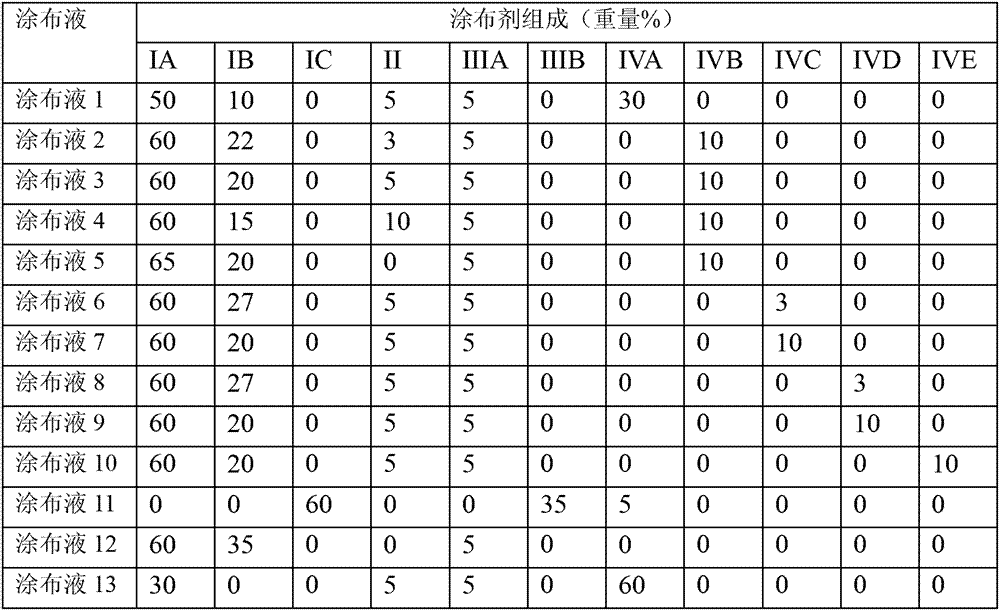

Embodiment 1

[0128] The mixed raw materials mixed with polyester (A), (B) and (C) at a ratio of 85%, 5%, and 10% are set as the raw materials of the outermost layer (surface layer), and 95%, 5%, and The mixed raw materials mixed with polyester (A) and (B) in the proportion of % are used as the raw materials of the middle layer, and are respectively supplied to two extruders. A layer structure of 3 layers (surface layer / intermediate layer / surface layer = 1:18:1 discharge rate) was co-extruded and allowed to cool and solidify to obtain an unstretched sheet. Next, the film was stretched 3.4 times in the longitudinal direction at a film temperature of 85° C. by using the difference in the peripheral speed of the rollers, and the coating liquid 1 shown in the following Table 1 was dried to 0.09 g / m on one surface of the longitudinally stretched film. 2 Coating in the same way, on the surface of the opposite side, the coating liquid 11 is dried to 0.03g / m 2 Coating was carried out in a tenter, ...

Embodiment 2~10

[0131] In Example 1, except having changed the coating liquid composition into the coating liquid composition shown in Table 1, it manufactured similarly to Example 1, and obtained the polyester film. The properties of the produced polyester film are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com