Anti-sticking paper preparation method with low consumption of silicone oil

A technology of anti-adhesive paper and low consumption, which is applied in the direction of paper, papermaking, textiles and papermaking, etc. It can solve the problems of high manufacturing cost and large amount of anti-adhesive paper silicone oil, and achieve lower production costs, good anti-adhesive performance, and reduced use. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

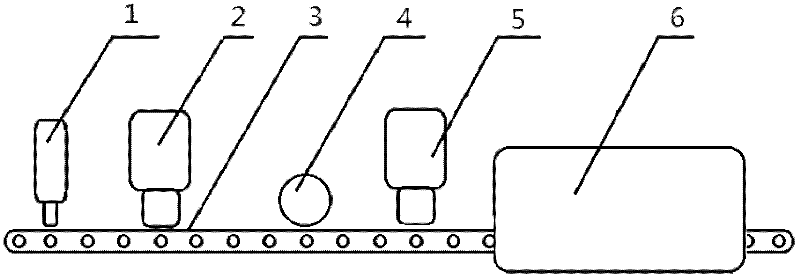

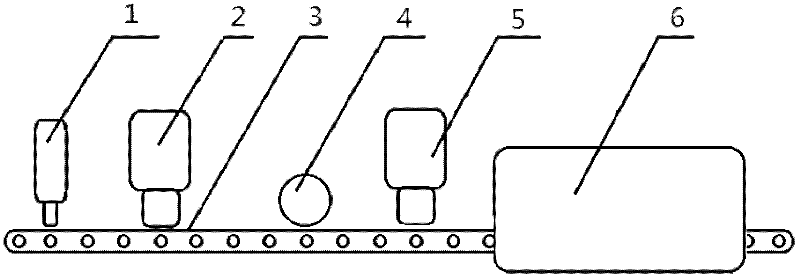

[0026] (1) Use a corona treatment machine to treat the surface of the backing paper of the release paper with a power of 400W for 180s.

[0027] (2) Mix polyethylene and acrylic acid-modified polyethylene in a ratio of 1:0.1, first pass through a temperature of 180°C for bridging, then increase the temperature to 280°C, and apply a pressure of 10Mpa to squeeze it after melting out, keep the temperature at around 320°C when laminating. After coating, the coated paper is obtained, and the coating amount is 10g / m 2 .

[0028] (3) The conveyor belt sends the coated paper to the roller with concave and convex embossing at a transmission speed of 100m / min for rolling.

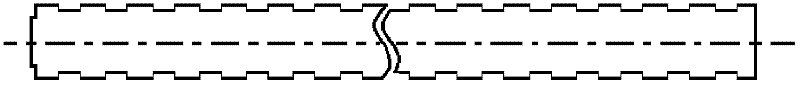

[0029] After rolling, the surface of the coated paper presents concave-convex embossed grooves. Concave-convex embossing groove, the width of the convex surface is 10mm, the height of the concave-convex groove is 1.8mm, and the width of the bottom surface of the groove is 13mm. Cooled coated paper with concave an...

Embodiment 2

[0033] (1) Use a corona treatment machine to treat the surface of the backing paper of the release paper with a power of 500W for 180s.

[0034] (2) Mix polyethylene and acrylic acid-modified polypropylene in a ratio of 1:0.5, first pass through a temperature of 250°C for bridging, then increase the temperature to 300°C, and apply a pressure of 20Mpa after melting It is extruded and kept at a temperature of about 380°C when laminating. After coating, the coated paper is obtained, and the coating amount is 6g / m 2 .

[0035] (3) The conveyor belt sends the coated paper to the roller with concave and convex embossing at a transmission speed of 90m / min for rolling.

[0036] After rolling, the surface of the coated paper presents concave-convex embossed grooves. Concave-convex embossed groove, the width of the convex surface is 10mm, the height of the concave-convex groove is 0.6mm, and the width of the bottom surface of the groove is 10mm. Cooled coated paper with concave and ...

Embodiment 3

[0040] (1) Use a corona treatment machine to treat the surface of the backing paper of the release paper with a power of 370W for 180s.

[0041] (2) Mix polyethylene and acrylic acid-modified polyethylene in a ratio of 1:0.3, first heat the bridge at 200°C, then increase the temperature to 350°C, and apply a pressure of 16Mpa to squeeze it after melting out, keep the temperature at around 330°C when laminating. After coating, the coated paper is obtained. The amount of coating is 20g / m 2 .

[0042] (3) The conveyor belt sends the coated paper to the roller with concave and convex embossing at a transmission speed of 80m / min for rolling.

[0043] After rolling, the surface of the coated paper presents concave-convex embossed grooves. Concave-convex embossing groove, the width of the convex surface is 10mm, the height of the concave-convex groove is 1.5mm, and the width of the bottom surface of the groove is 12mm. Cooled coated paper with concave and convex grooves.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com