Patents

Literature

32results about How to "Good anti-sticking properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel used for straight seam electric resistance welding petroleum casing and casing manufacturing method

ActiveCN101798654AHigh strengthImprove toughnessFurnace typesProcess efficiency improvementWeld seamElectric resistance welding

The invention relates to a steel used for straight seam electric resistance welding petroleum casing and a casing manufacturing method, which is applied to a straight seam electric resistance welding petroleum casing used for an oil and gas well in petroleum and gas industry. The steel used for the straight seam electric resistance welding petroleum casing comprises the following components in percentage by mass: 0.15-0.28% of C, 1.0-1.6% of Mn, 0.2-0.4% of Si, 0. 02-0.06% of Al, less than or equal to 0.01% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, 0.001-0.005% of Ca and the balance of Fe. The preparation method comprises the steps of: preparing hot-rolled plate coils, producing straight seam electric resistance welding steel pipes by the hot-rolled plate coils, carrying out welding seam normalization or overall normalization on the welded steel pipes, straightening and cutting the normalized or tempered welded steel pipes into pipe segments with the length of 10-12m, and processing API standard screw threads. The invention has the advantages that the steel has good strength and toughness, the welding seam has no defect, and the properties of the steel are uniform with those of mother material. The yield strength is greater than or equal to 380-760MPa, the tensile strength is greater than or equal to 520-865MPa, the elongation is greater than or equal to 20%, and the impact energy of a room-temperature transverse full-size V-shaped notch is greater than or equal to 40J.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High hydrophobic anti pasting poster paint

ActiveCN101550303AImprove surface hydrophobicityStrong surface anti-adhesionCoatingsEmulsionPreservative

A high hydrophobic anti pasting poster paint, which is characterized in that the coating includes following components, weight parts of each is: water 20-40, thickening agents 0.1-3, AMP 95 0.1-0.5, dispersant 0.2-2, defoamer 0.1-0.5, color filling agent 20-50, hydrophobic surface anti pasting agent 0.1-0.5, emulsion 10-40, film-forming additive 0-2, preservative agent 0.1-1. the color filling agent is composed of diatomite or calcium carbonate matching with quartz powder and titanium dioxide and mixing, wherein the weight ratio of diatomite or calcium carbonate: quartz powder: titanium dioxide is 1: 0.5-5.5: 1-5. The present invention is provided with characteristics of high surface hydrophobic nature and surface anti pasting ability after film-forming, not easy to doodle or covered by sewerage or other coatings, and not easy to be pasted by common advertisement sticker with gum in the back, stable property, simple production process and convenient for construction.

Owner:GUANGDONG HUARUN PAINT CO LTD

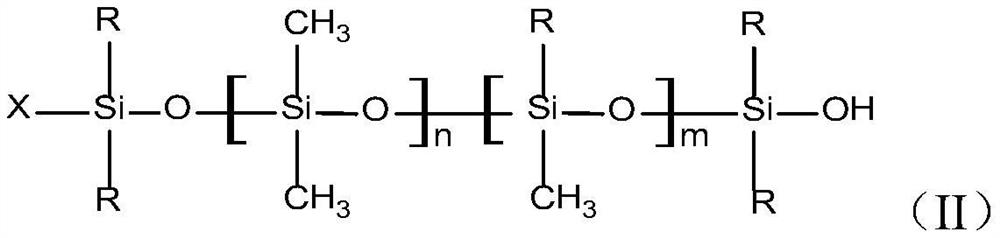

An anti-graffiti coating composition

A coating composition, which is one-component or two-component, comprising an alkoxy- functional silicone resin, a hydroxy silicone oil having a dynamic viscosity of not more than 1,000 mPas at 25 DEGC, an aminosilane, and a catalyst, wherein the alkoxy-functional silicone resin and the hydroxyl silicone oil are in different components in a two-component coating composition. The coating composition herein is silicone-based and has excellent anti-graffiti and anti-stick properties. Moreover, the coating composition can be solvent free.

Owner:WACKER CHEM GMBH

Additive for neutral desizing, oil removing and one-bath dyeing of chemical fiber fabrics and preparation method thereof

ActiveCN103741513AImprove performanceShort processFibre typesDry-cleaning apparatus for textilesFiberSulfonate

The invention relates to an additive for neutral desizing, oil removing and one-bath dyeing of chemical fiber fabrics and a preparation method thereof. Currently, no additives for neutral desizing, oil removing and one-bath dyeing of chemical fiber fabrics or preparation methods thereof are provided with excellent performance, energy saving, and consumption saving. The additive for neutral desizing, oil removing and one-bath dyeing of chemical fiber fabrics provided by the invention comprises 15-25 parts by weight of ANCconc, 15-30 parts of FMES, 5-15 parts of NPP, 5-10 parts of NA, 5-10 parts of penetrants, and 30-50 parts of water, wherein ANCconc is a surfactant with cleaning and anti-contamination functions, FMES is a sulfonate of fatty acid methyl ester ethoxylate, NPP is an oligomer remover, and NA is a multipurpose dispersant. The additive for neutral desizing, oil removing and one-bath dyeing of chemical fiber fabrics provided by the invention has excellent performance, allows the desizing, oil removing and one-bath dyeing processes of chemical fiber fabrics to be carried out under a neutral condition, and can realize direct dyeing without water washing, acid neutralization, or operating fluid discharge.

Owner:JIANGSU NEW REBA TECH CO LTD

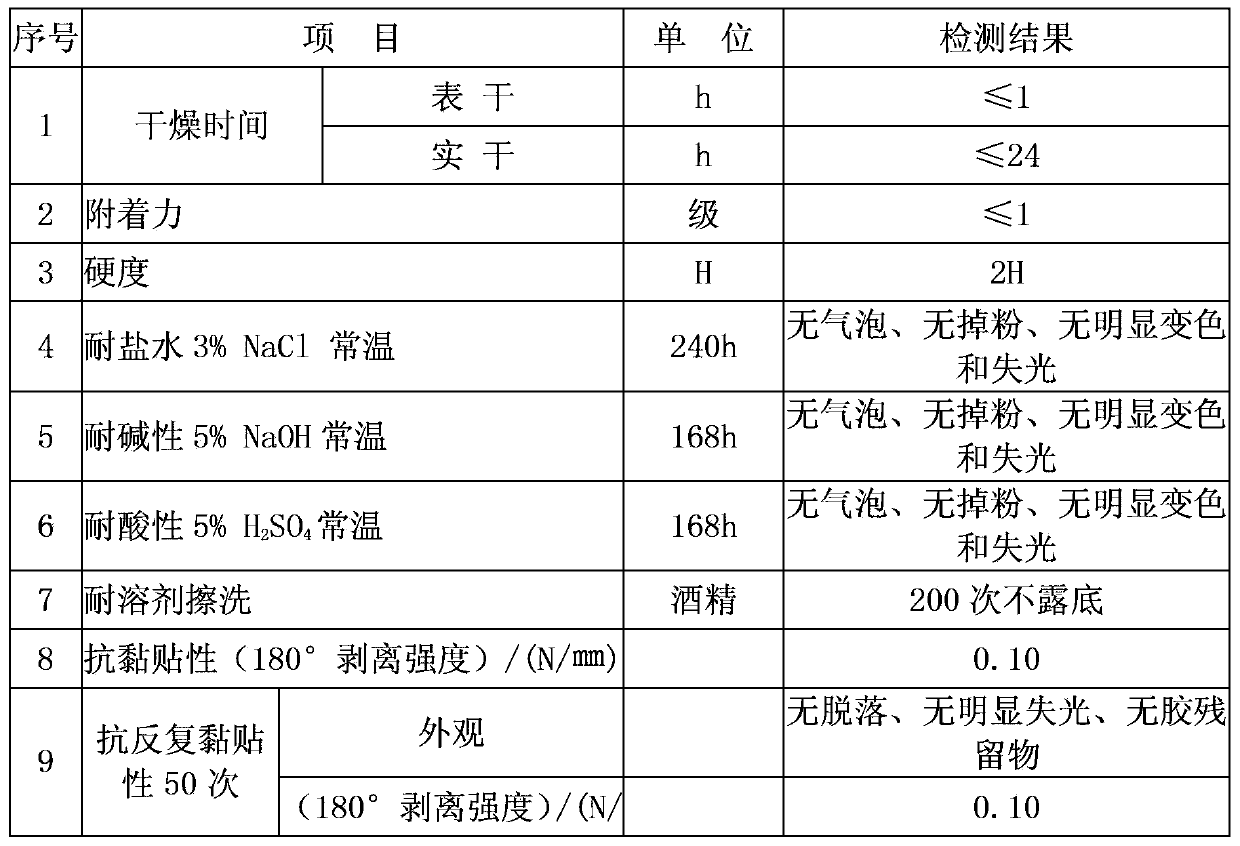

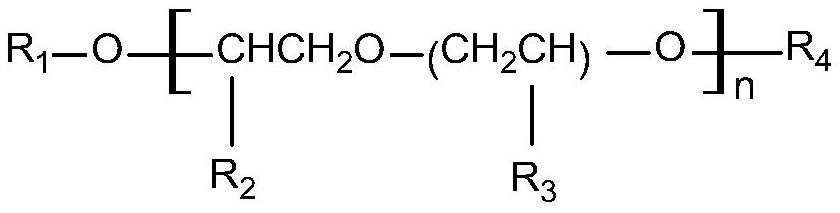

Durable scrawling-preventive anti-paste paint capable of being repeatedly coated, and preparation method thereof

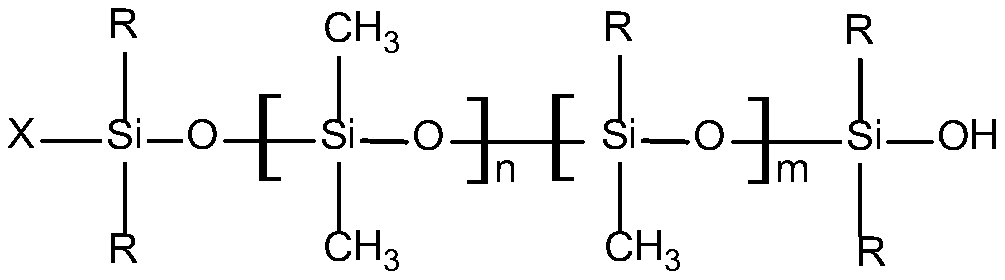

InactiveCN103360875AGood anti-sticking propertiesIncreased durabilityCoatingsActive agentBULK ACTIVE INGREDIENT

The invention relates to a durable scrawling-preventive anti-paste paint capable of being repeatedly coated, and a preparation method thereof. The urable scrawling-preventive anti-paste paint comprises the following components in parts by weight: 60-70 parts of modified silicon resin, 0.5-2 parts of levelling agent, 0.2-1 parts of non-ionic type active agent, 25-30 parts of rutile type titanium dioxide, 0.2-1 part of defoaming agent, 1-3 parts of surface tension equilibrium catalyst, 0.5-3 parts of nanometer SiO2, 0.2-1 part of dispersing agent, 0-13 parts of curing agent, 3-5 parts of acetic ether, 7-10 parts of n-butyl acetate; the modified silicon resin comprises active ingredients in parts by mass: 70-75 parts of fluorocarbon resin, 13-16 parts of polydimethylsiloxane, 0.5-1 part of coupling agent, 0.3-0.4 part of reaction accelerator, and 8-10 parts of n-butyl acetate. While the better anti-paste effect of the paint can be maintained, the durability can be greatly improved, and the paint has no barriers when being repeatedly coated, and is convenient to repair.

Owner:JIANGSU HAIYAO CHEM

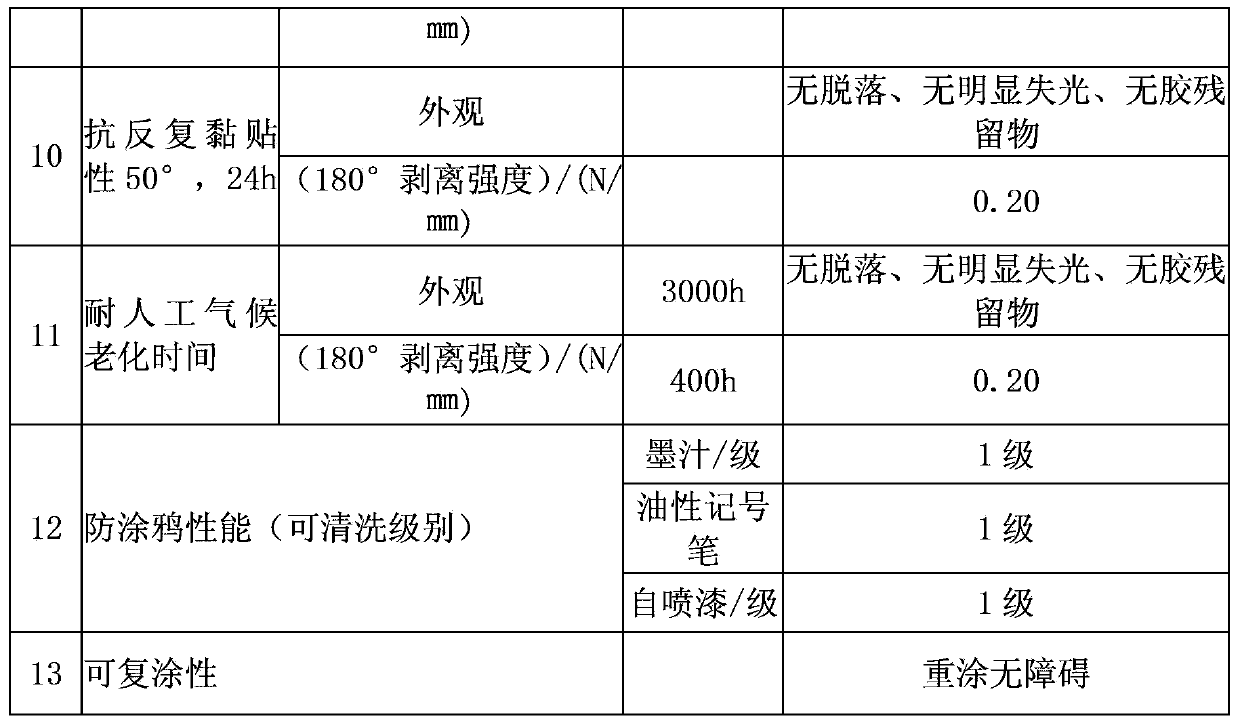

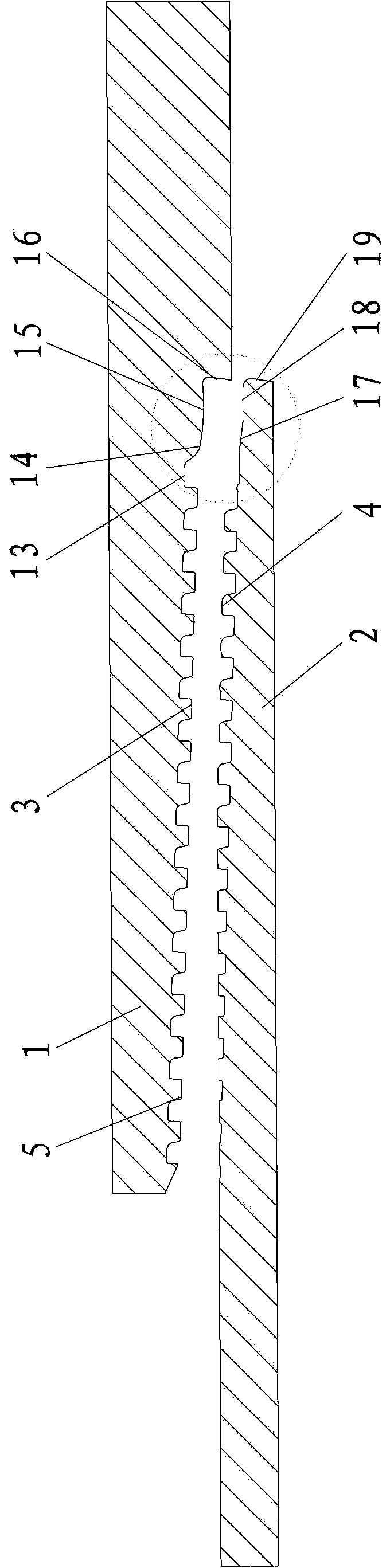

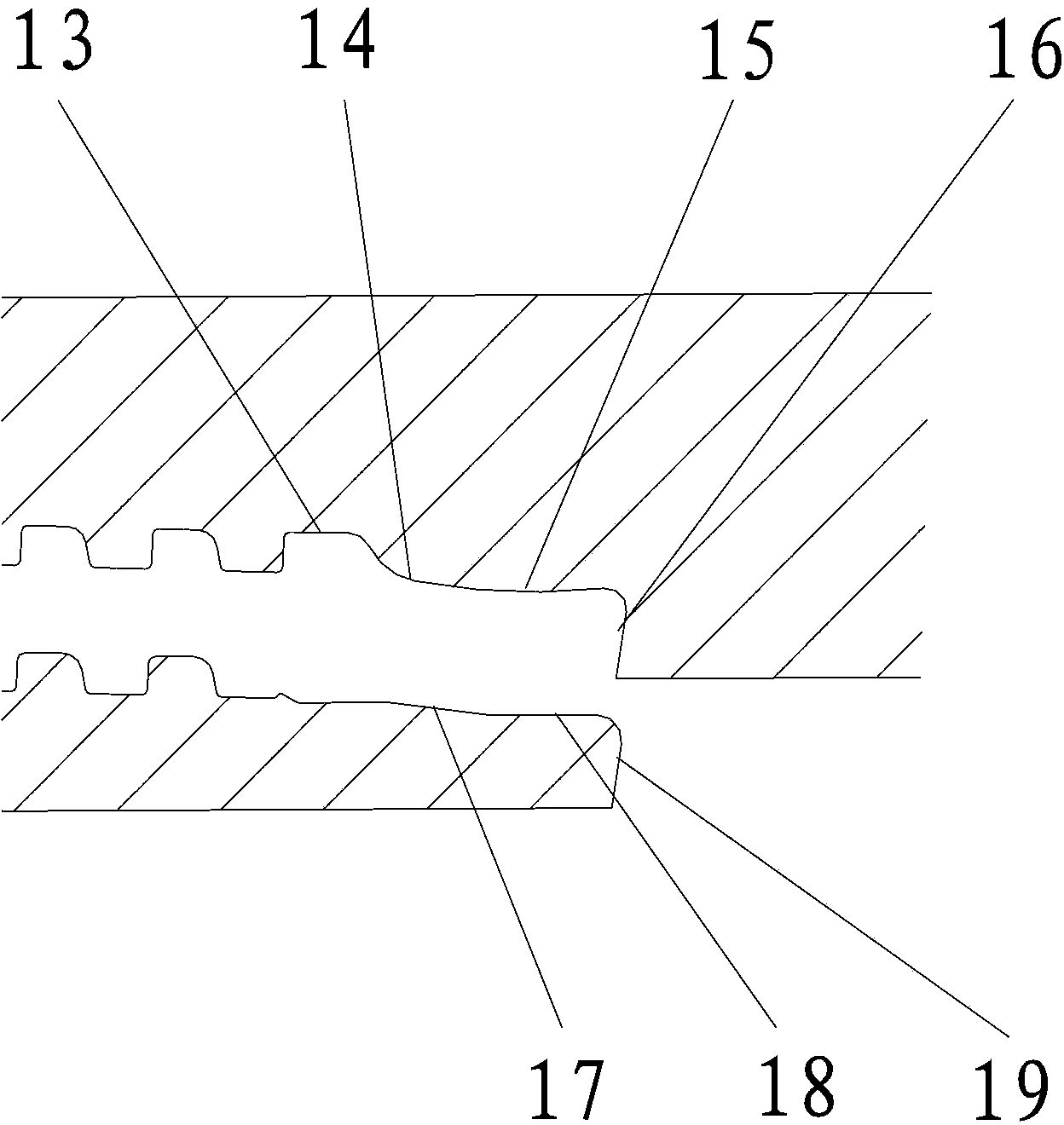

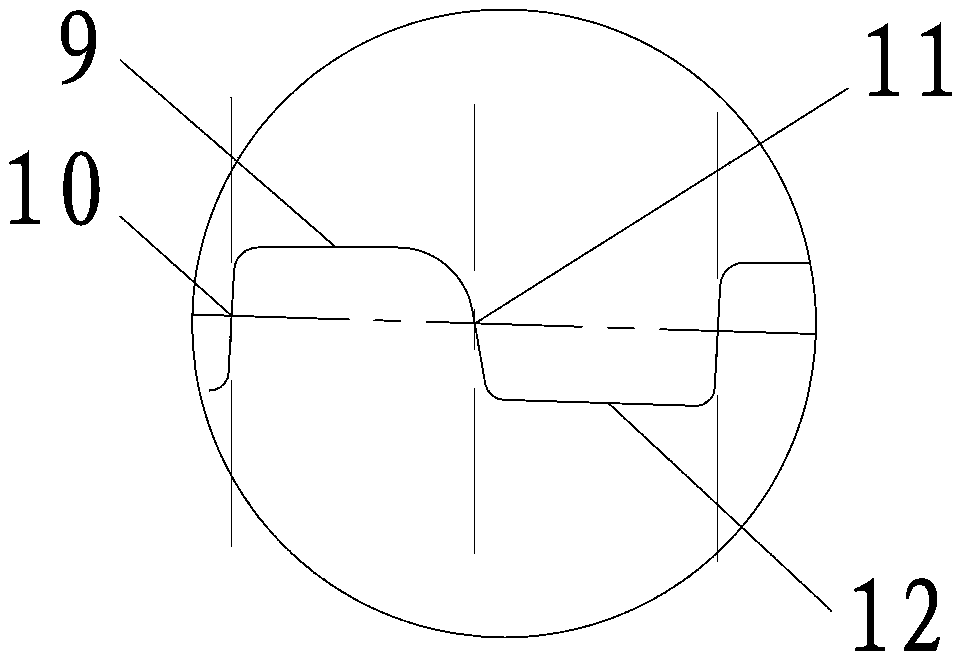

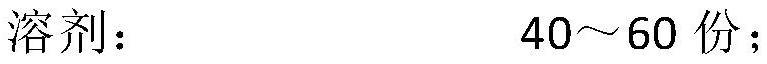

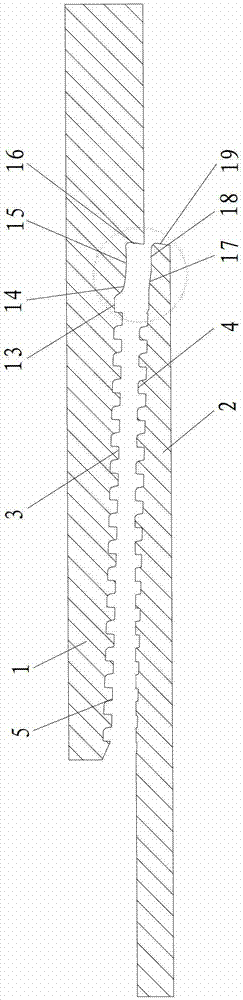

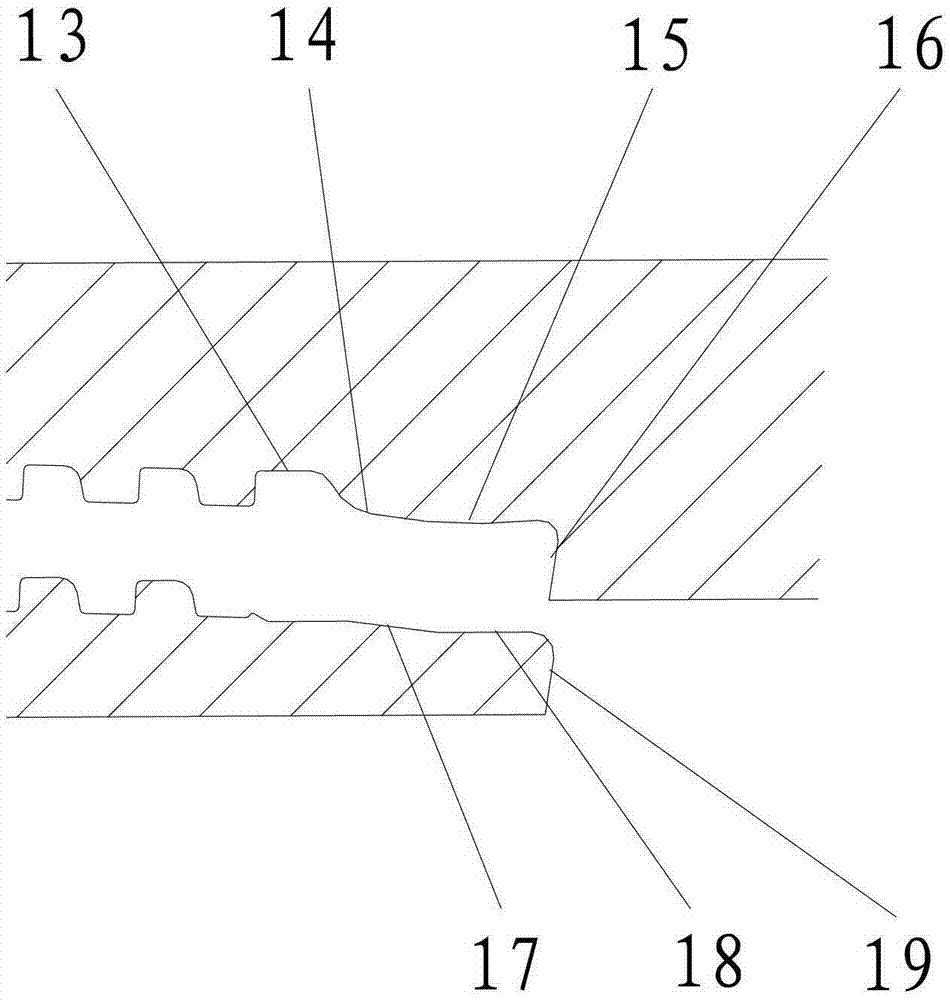

Multistage sealing anti-sticky buckle type thread for titanium alloy oil casing

InactiveCN103527110AImprove airtight reliability performanceReduced stress stateDrilling rodsDrilling casingsButtressCoupling

The invention relates to a multistage sealing anti-sticky buckle type thread for a titanium alloy oil casing. The multistage sealing anti-sticky buckle type thread comprises an oil casing coupling and an oil casing tube end, the oil casing coupling is provided with a standard API buttress internal thread which is sequentially connected with a tool withdrawal groove, a cone surface to cone surface first stage sealing structure, a cylinder surface to cylinder surface second stage sealing structure and a negative angle torque circular bead, wherein the cone surface to cone surface first stage sealing structure and the cylinder surface to cylinder surface second stage sealing structure are in transition through chambering, and the negative angle torque circular bead is connected with the standard API buttress internal thread through a transitional angle. The multistage sealing anti-sticky buckle type thread for the titanium alloy oil casing has the advantages that two stages of metal sealing and one negative angle torque circular bead sealing are added based on the improved buttress thread, the reliability of the air tightness of a thread connector is improved through the design of multistage sealing, meanwhile, the stress state of the thread connector is reduced by changing a thread parameter, the performance of an anti-sticky buckle is improved, and machining and detecting are convenient.

Owner:XIAN SANHUAN TECH DEV GENERAL

Micro arc oxidation composite stain resistant coating and production method thereof

InactiveCN109208054AAvoid disadvantagesPlay the role of crack preventionAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a micro arc oxidation composite stain resistant coating and a production method thereof. The production method specifically comprises the following steps that 1, a well prepared metal board substrate is mechanically polished, and the corners and the hiding parts are polished through manpower assistance; 2, the metal board substrate polished in the step 1 is placed into a ultrasonic cleaner to be rapidly washed by adding clean water and a sodium hydroxide solution and utilizing ultrasonic waves; 3, the washed metal board substrate in the step 2 is rapidly blown dry in warm air, the greasy stains and rusty spots on the surface of the substrate are removed; and 4, a micro arc oxidation electrolytic solution of potassium hydroxide, sodium sulfate and potassium fluorideis prepared and aged for stand-by application. The production method utilizes a coating machine to spray a layer of silicone fluoride modified coating on the surface of a ceramic layer, the silicone fluoride modified coating has the good anti-adhesion performance, anti-graffiti performance, outdoor durability, cold and hot resistance, stain resistance, anti-scrubbing performance and solvent resistance, and is waterproof and anti-creeping.

Owner:西安庄信新材料科技有限公司

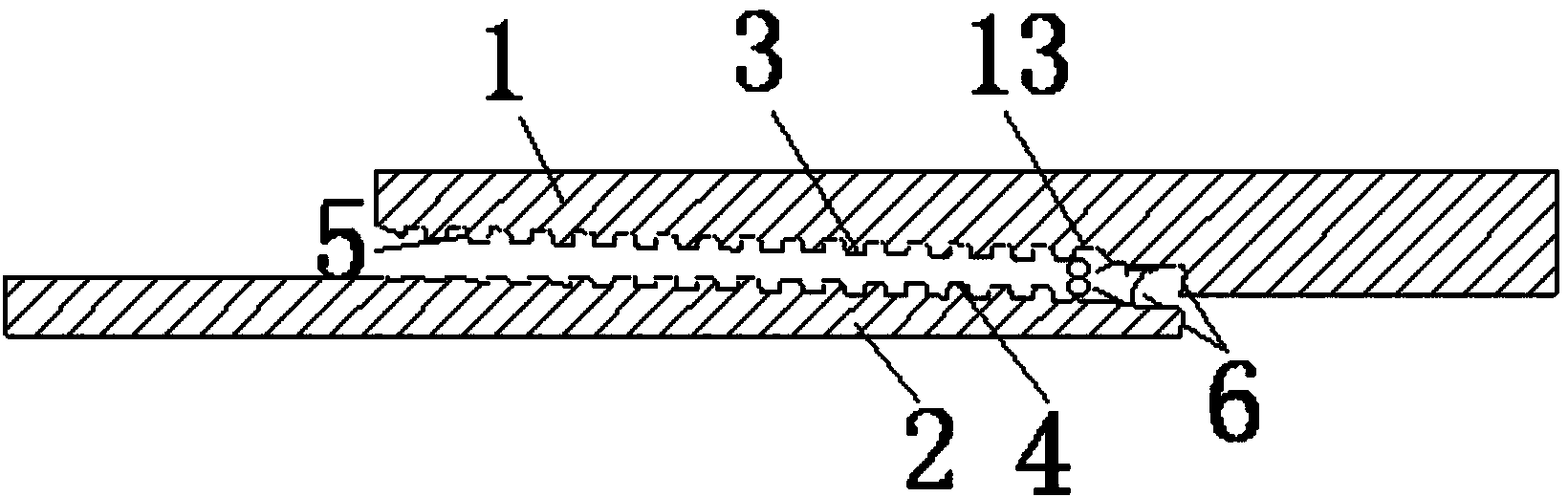

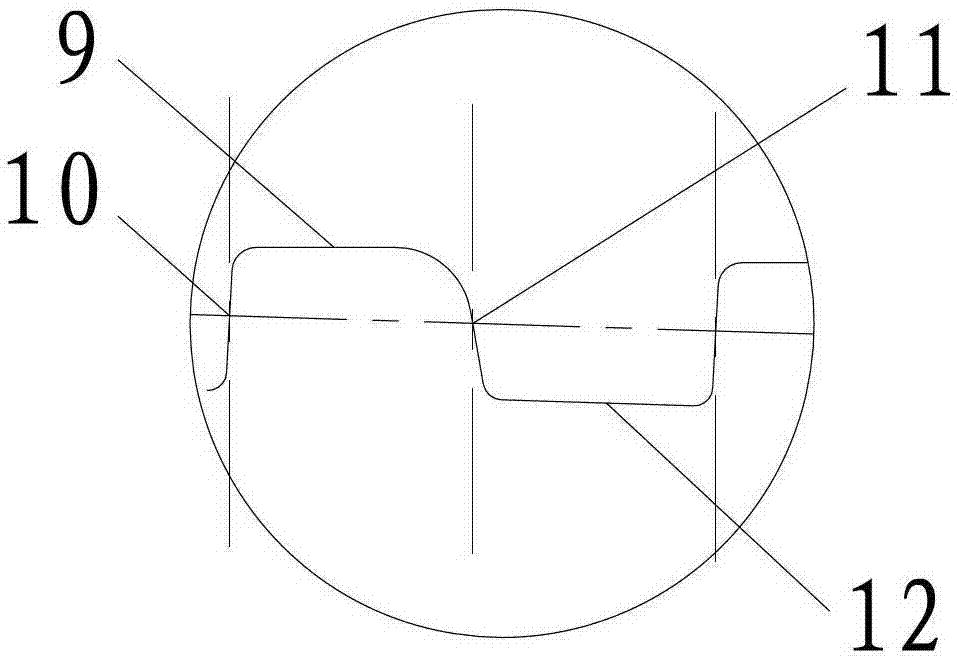

Anti-bonding three-stage end surface metal sealing threaded connector for titanium alloy pipe

ActiveCN103628827AImproves sealing reliabilityLow contact pressureDrilling rodsDrilling casingsButtressThree stage

The invention relates to a threaded structure for connection of a well completion production tubular column of the petroleum and gas industry, in particular to an anti-bonding three-stage end surface metal sealing threaded connector for a titanium alloy pipe. The anti-bonding three-stage end surface metal sealing threaded connector for the titanium alloy pipe comprises an oil casing collar and an oil casing end, wherein the oil casing collar is provided with an API buttress inner thread, the oil casing end is provided with a buttress outer thread matched with the API buttress inner thread, a tool withdrawal groove is formed in one end of the API buttress inner thread and is sequentially connected with an arc surface I and an arc surface II through chamfer transition, the arc surface II is connected with a negative angle torque lifting shoulder I through chamfer transition, a conical surface, a cylindrical surface and a negative angle torque lifting shoulder II are arranged at one end of the buttress outer thread, the conical surface and the cylindrical surface sequentially correspond to the arc surface I and the arc surface II, the negative angle torque lifting shoulder II corresponds to the negative angle torque lifting shoulder I, and after the oil casing collar is matched with the oil casing end in a threaded mode, interference sealing is carried out on metal through a first-stage sealing structure of the arc surface I on the conical surface, a second-stage sealing structure of the arc surface II on the cylindrical surface and third-stage metal of the sealing structure of the negative angle torque lifting shoulders. The anti-bonding three-stage end surface metal sealing threaded connector for the titanium alloy pipe improves the air sealing reliability, and has good anti-bonding performance.

Owner:忠世高新材料股份有限公司

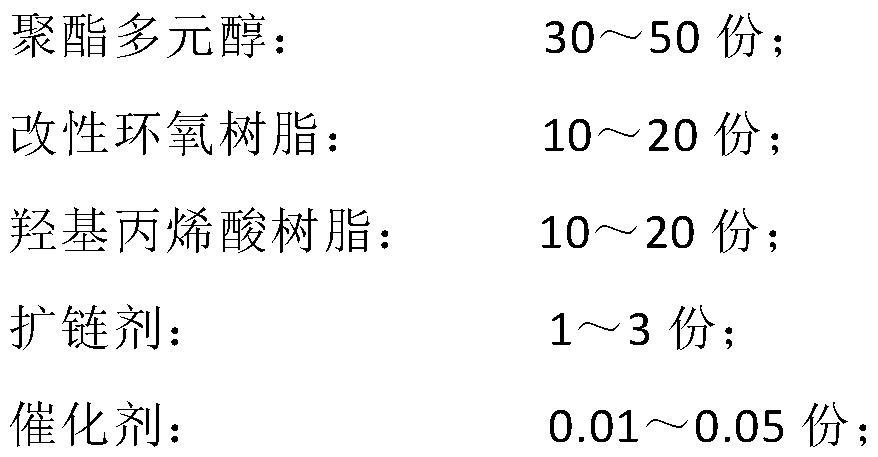

High-hydrolysis-resistant back-adhesion-resistant adhesive used for aluminum plastic composite tag and preparation of adhesive

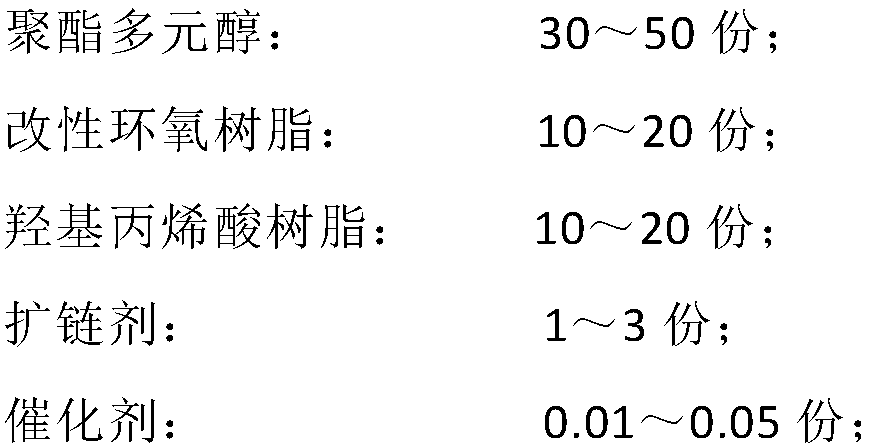

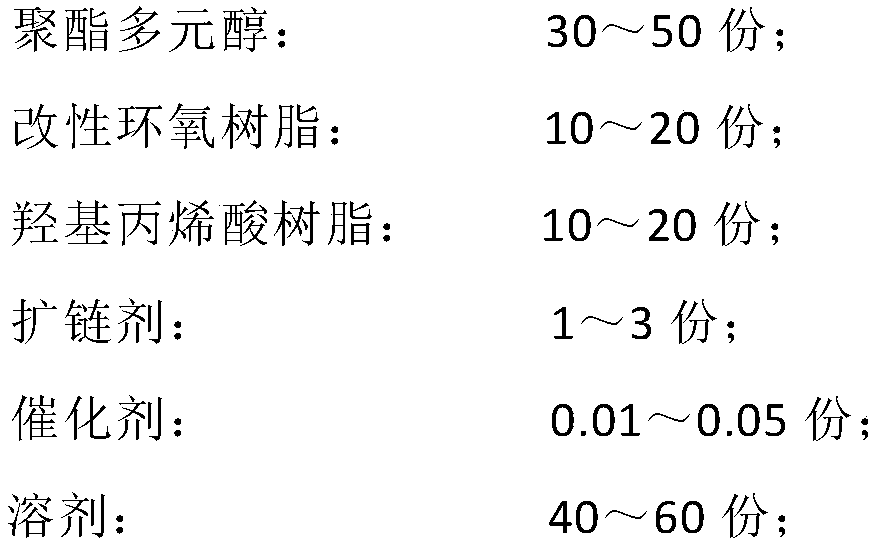

ActiveCN109337634ASuitable for bondingHigh bonding strengthPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a high-hydrolysis-resistance anti-sticking backing adhesive used for an aluminum plastic composite tag and preparation of the adhesive. The adhesive comprises a component A anda component B, wherein the component A comprises polyester polyol, modified epoxide resin, hydroxy acrylic resin, a chain extender, a catalyst and a solvent; and the component B comprises an initiator and an isocyanate curing agent. The adhesive disclosed by the invention is particularly applicable to the adhesion of an aluminum foil or an aluminum coating and a PET thin film; the adhesive is high in adhesive strength to an aluminum plastic composite material and has good acid and alkaline resistance and damp-heat aging resistance, and high back adhesion resistance exists between adhesive layers and between an adhesive layer and aluminum respectively when the adhesive disclosed by the invention is applied; and after an etching technology of the aluminum plastic composite tag, the tag cannot be destroyed by back adhesion even if unrolling or rolling.

Owner:SHANGHAI WEIKAI CHEM +2

High-strength sealing thread compound for deep well pipe column and preparation method

The invention relates to a joint of a drill rod, an oil pipe, a sleeve and other oil well pipes for drilling operation in a deep well and an ultra-deep well, a high-strength sealing thread compound for a pipe column of a deep well to improve thread connecting performance of the pipe column and a method for preparing the thread compound. The thread compound consists of two compositions A and B which are mixed; the composition A comprises the following compositions by weight percentage: 10 to 15 percent of E51 epoxy resin, 1 to 8 percent of carboxy nitrile rubber, 15 to 30 percent of AG epoxy resin, 2 to 10 percent of 501 thinner, 3 to 12 percent of butyronitrile, 15 to 30 percent of aluminium oxide, 5 to 16 percent of aluminum powder and 1 to 5 percent of aerosil; the composition B consists of a condensed amino-105 epoxy curing agent; and according to the composition A being 100 weight percent, the addition amount of the composition B is 5 to 10 percent of the weight of the composition A. The thread compound has good high-temperature resistance, can effectively prevent a connecting part of the underground pipe column of the deep well from loosening, can ensure the sealing performance at high temperature and simultaneously increases the connecting strength between the oil pipe column and the sleeve pipe column.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Surface coating for building aluminum alloy template capable of preventing concrete adhesion and preparation method of surface coating

The invention discloses a surface coating for a building aluminum alloy template capable of preventing concrete adhesion and a preparation method of the surface coating. The surface coating for the building aluminum alloy template capable of preventing concrete adhesion is prepared from the following raw materials in parts by mass: 15 to 30 parts of modified epoxy resin, 5 to 15 parts of modifiedtitanium dioxide, 15 to 25 parts of polytetrafluoroethylene powder, 30 to 50 parts of ethyl acetate, 5 to 10 parts of N-methyl-2-pyrrolidone, 0.5 to 3 parts of a curing agent and 0.5 to 3 parts of a defoaming agent. The anti-sticking performance, the chemical stability, the heat resistance, the mechanical performance and other performance of the coating are improved by blending the modified epoxyresin, the modified titanium dioxide and the polytetrafluoroethylene powder; the epoxy resin not only has excellent adhesion to metals, but also has lower surface energy after film formation by modifying the epoxy resin, thereby being beneficial to the anti-sticking performance of the coating.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

Waterborne polyurethane for food or medicine packaging lamination composite and preparation method thereof

ActiveCN104152101AHigh solid contentLow viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDefoamerSubstance content

The invention provides waterborne polyurethane for food or medicine packaging lamination composite and a preparation method thereof. The waterborne polyurethane is prepared by compounding the following components in parts by weight: 100 parts of acrylate modified waterborne polyurethane dispersion, 0.05 to 0.25 part of a wetting agent, 0.05 to 0.2 part of a flatting agent, and 0.1 to 0.2 part of a defoamer. The waterborne polyurethane has the advantages of high solid content, low viscosity, stick prevention, good water resistance, good levelling property, yellowing resistance, low readily oxidizable substance content and the like, can be applied to the lamination composite of food or medicine packaging material, and can also be applied to fields of water-based paint, wood lacquer, printing ink and the like.

Owner:NANJING UNIV OF TECH

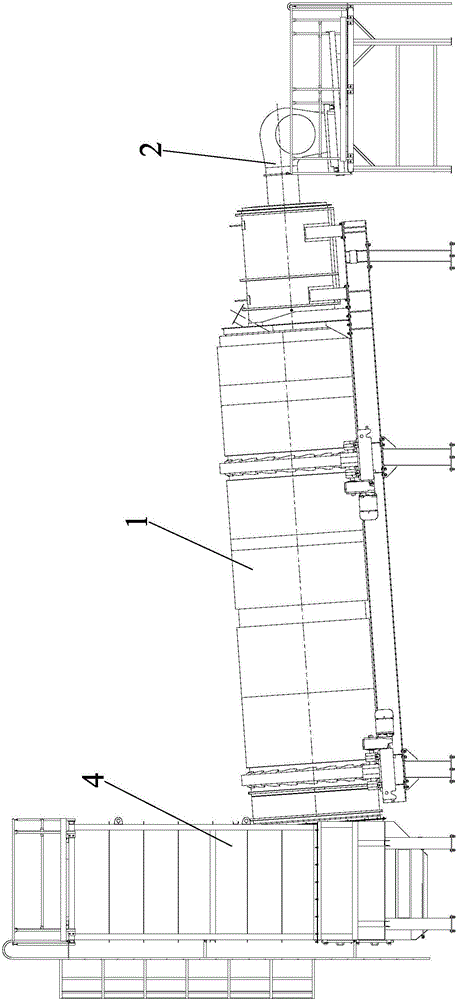

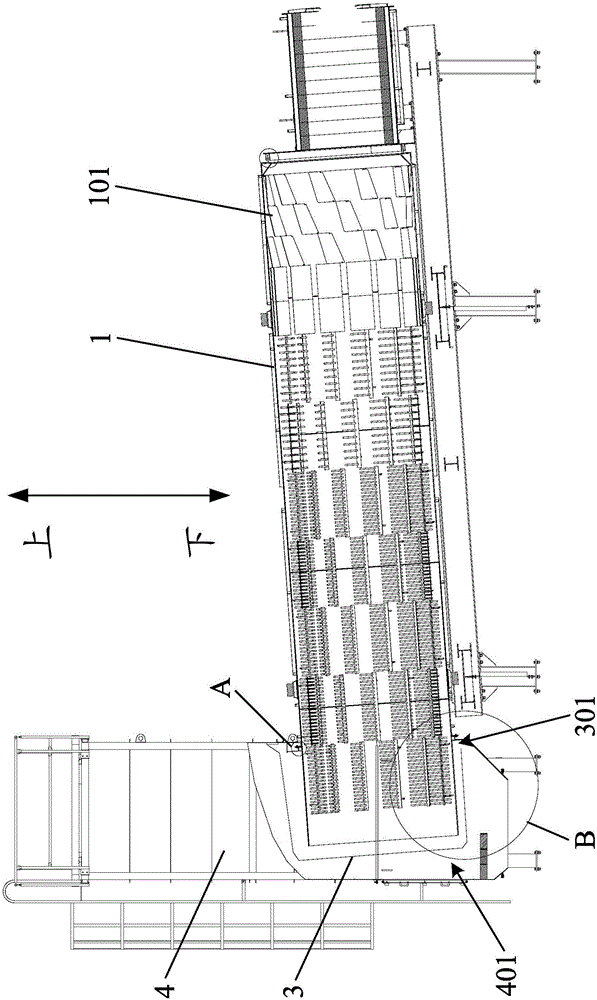

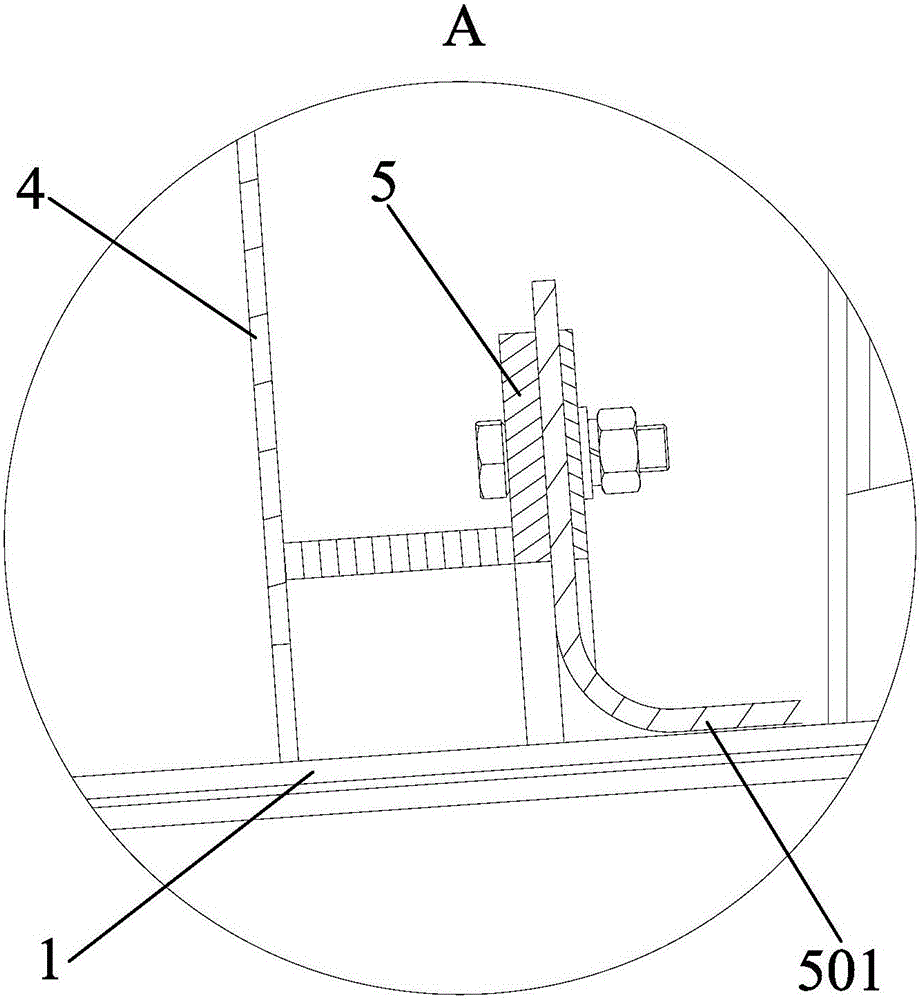

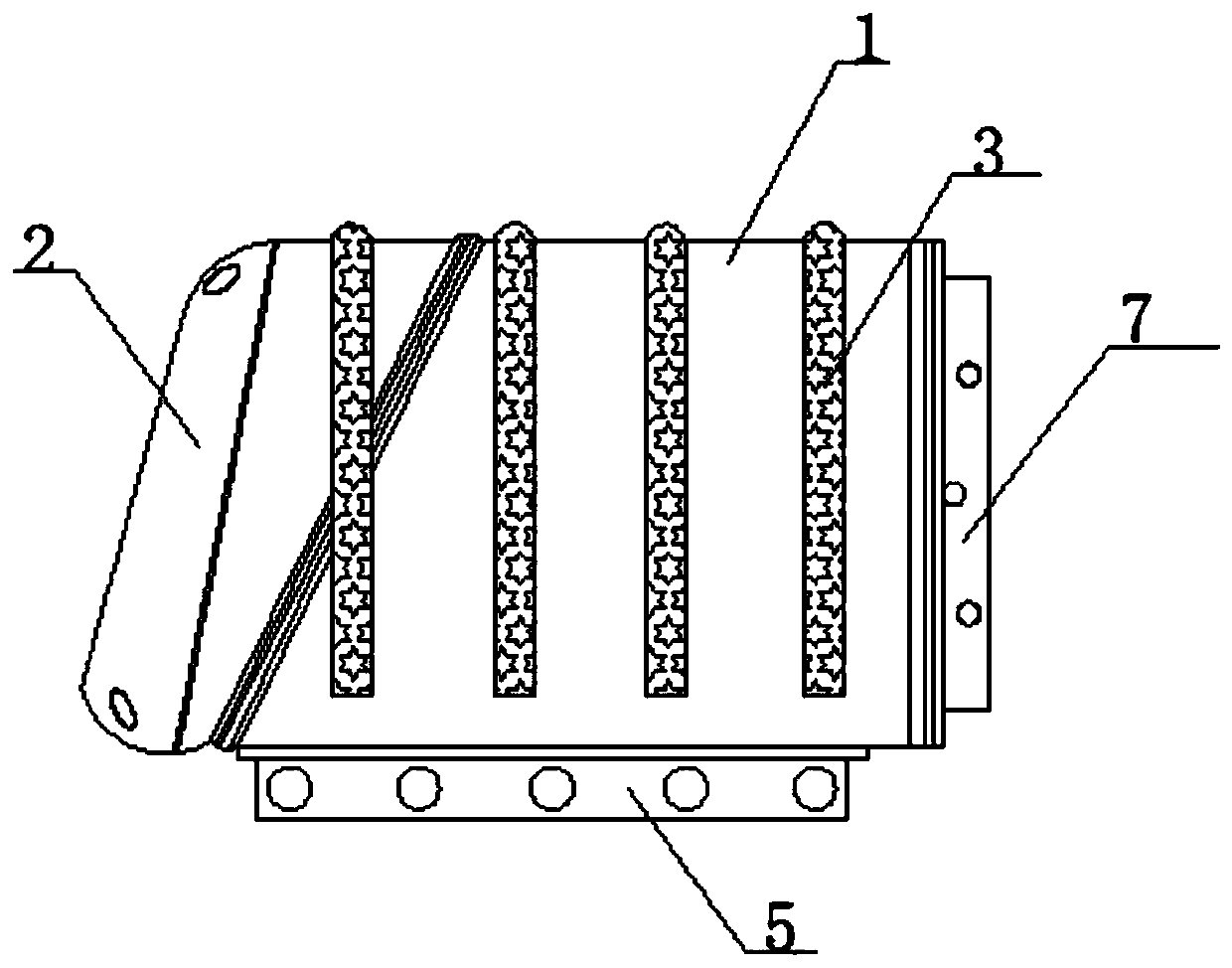

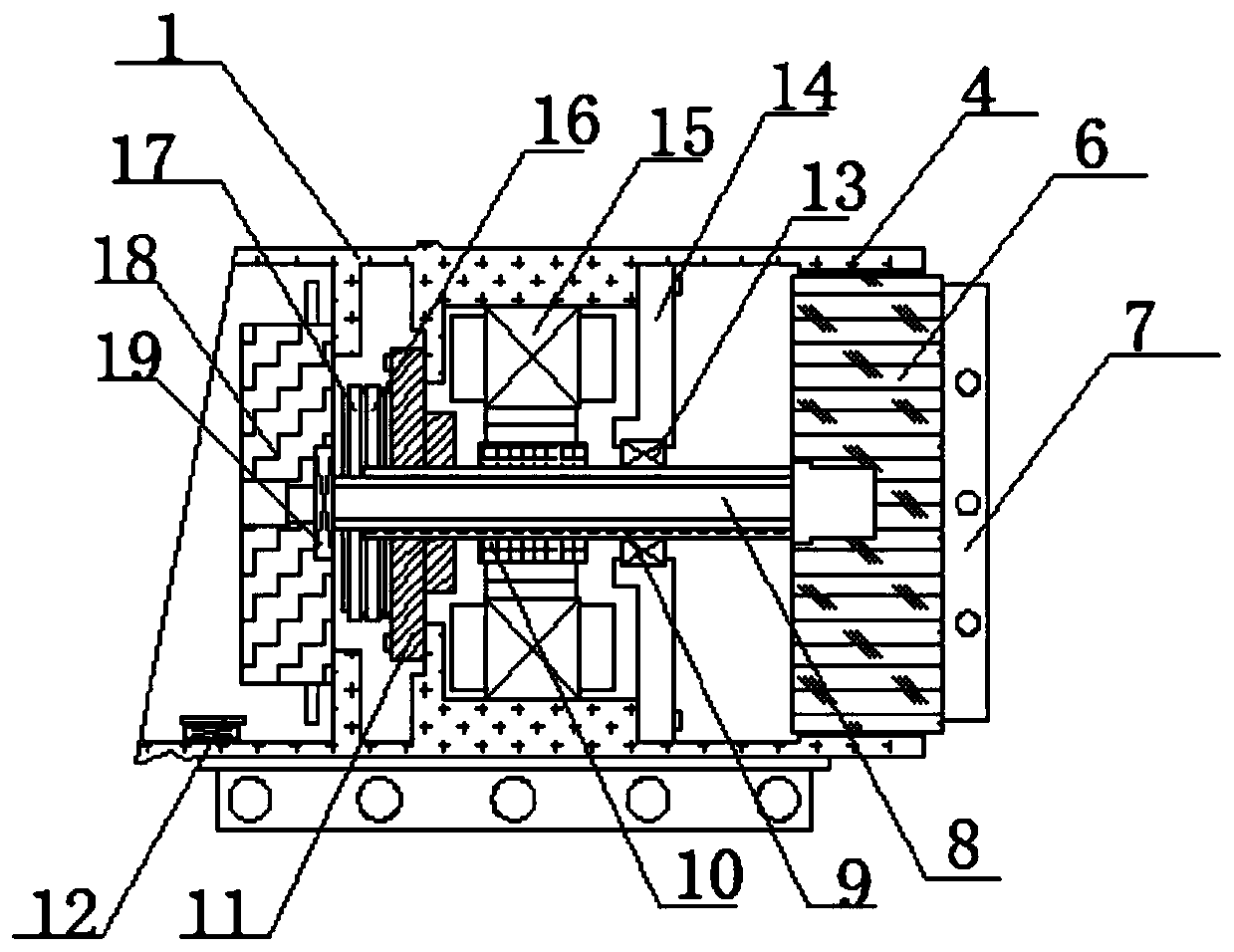

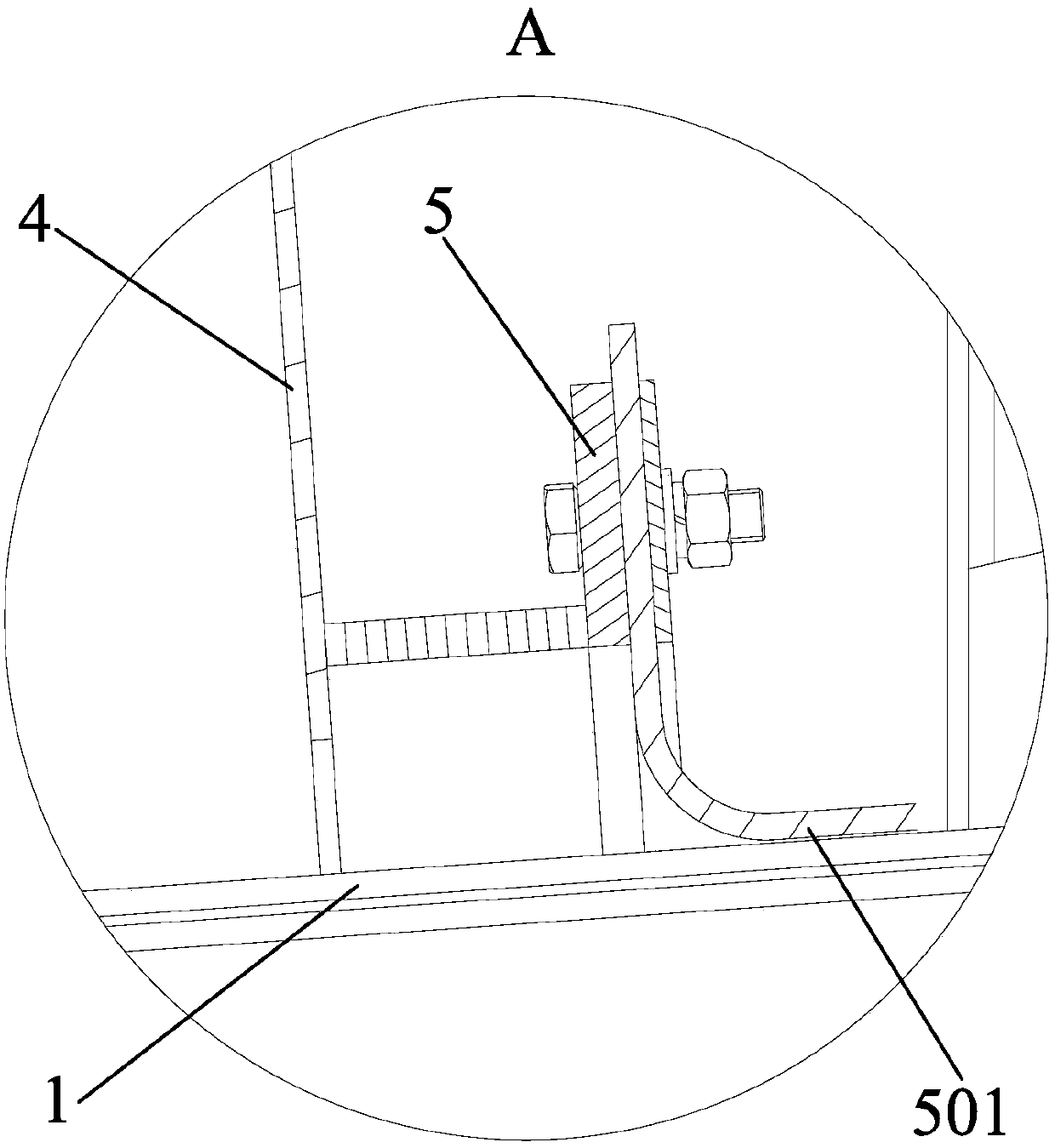

Recycled asphalt heating device

ActiveCN105951561AImprove formation qualityImprove heating efficiencyRoads maintainenceProduct gasAsphalt

The invention provides a recycled asphalt heating device which comprises a rotary drum, a heater and an air guide and reflux device, wherein the rotary drum is provided with a material feeding end and a material discharging end; the heater is connected with the material feeding end and is used for injecting high-temperature gas into the rotary drum; the air guide and reflux device is arranged at the material discharging end of the rotary drum and is used for heating the outer wall of the material discharging end through the gas flowing out of the material discharging end. According to the recycled asphalt heating device provided by the invention, the air guide and reflux device is arranged at the material discharging end of the rotary drum, so that the air guide and reflux device can be used for guiding the gas discharged from the material discharging end to the outer side wall of the material discharging end of the rotary drum, to enable the gas discharged from the material discharging end to heat a material in the rotary drum again, and temperature reduction of the material discharging end of the rotary drum can be slowed down. Therefore, the phenomenon that the material is attached to the inner wall of the material discharging end of the rotary drum and a material raising device due to extremely low temperature is avoided, the forming quality of a material curtain is effectively enhanced, the heating efficiency of a product is improved, the cleaning period of the rotary drum is correspondingly prolonged, and continuous production of the product is guaranteed.

Owner:HUNAN SANY ROAD MACHINERY

Printing paint for self-luminous advertisements and preparation method thereof

InactiveCN107141926AAvoid crackingStrong crack resistanceLuminescent paintsEpoxy resin coatingsEpoxyPolymer science

The invention discloses a printing paint for self-luminous advertisements. The printing paint comprises the following raw materials by weight: 25 parts of acrylic resin, 3 parts of rare earth luminescent powder, 10 parts of polyethylene wax, 5 parts of propyl acetate, 5 parts of epoxy resin, 2 parts of propylene glycol methyl ether acetate, 1 part of dimethyl carbonate, 2 parts of a thickening agent, 2 parts of an active diluent, 1 part of a leveling agent, 2 parts of a preservative, 20 parts of an organic solvent, an d1.5 parts of a surface hydrophobic anti-sticking assistant. According to the printing paint for self-luminous advertisements and a preparation method thereof provided by the invention, the prepared printing paint does not crack easily, has strong cracking resistance, can withstand whatever weather and the erosion of rainwater. The paint uses acrylic resin and rare earth luminescent powder as the carrier, adopts the organic solvent as the solvent, and is added with the surface hydrophobic anti-sticking assistant, and after the paint forms a film, the surface contact angle is small, and the adhesion resistance is good.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

A kind of food or pharmaceutical packaging laminated composite water-based polyurethane and preparation method thereof

ActiveCN104152101BEasy to useResistant to yellowingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater basedPolyurethane dispersion

The invention relates to a water-based polyurethane for food or medicine packaging lamination and compounding and a preparation method thereof. The food or pharmaceutical packaging lamination composite water-based polyurethane of the present invention is composed of 100 parts by mass of acrylate modified water-based polyurethane dispersion, 0.05-0.25 parts by mass of wetting agent, 0.05-0.2 parts by mass of leveling agent and 0.1-0.2 parts by mass of Compounded with defoamer. The water-based polyurethane has the advantages of high solid content, low viscosity, no anti-sticking, good water resistance, good leveling, good yellowing resistance, low oxidation, etc. It can be used for lamination and compounding of food or pharmaceutical packaging materials, and can also be used Used in water-based paint, wood paint, ink and other fields.

Owner:NANJING TECH UNIV

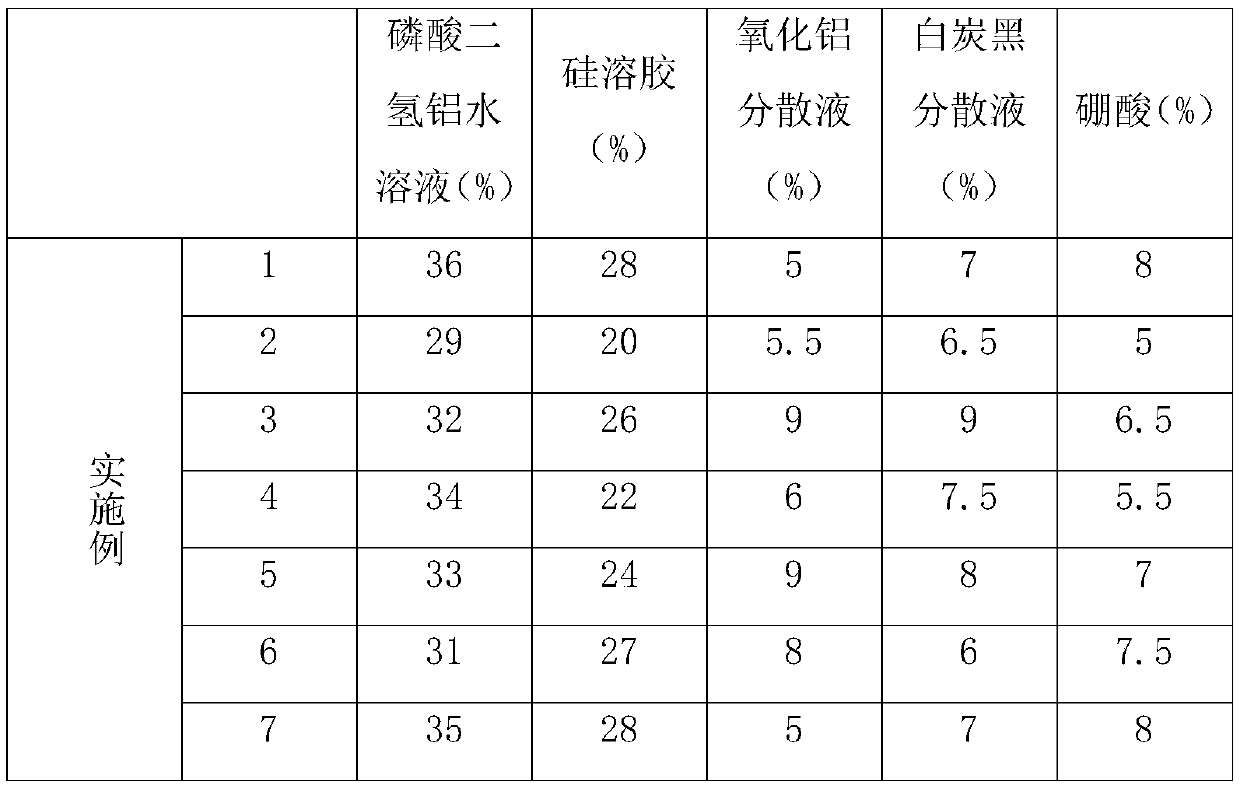

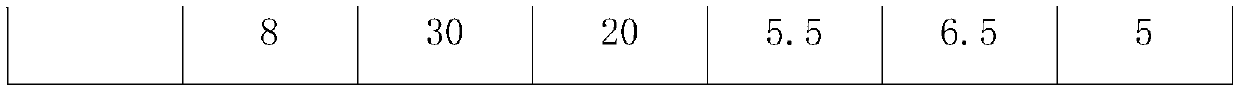

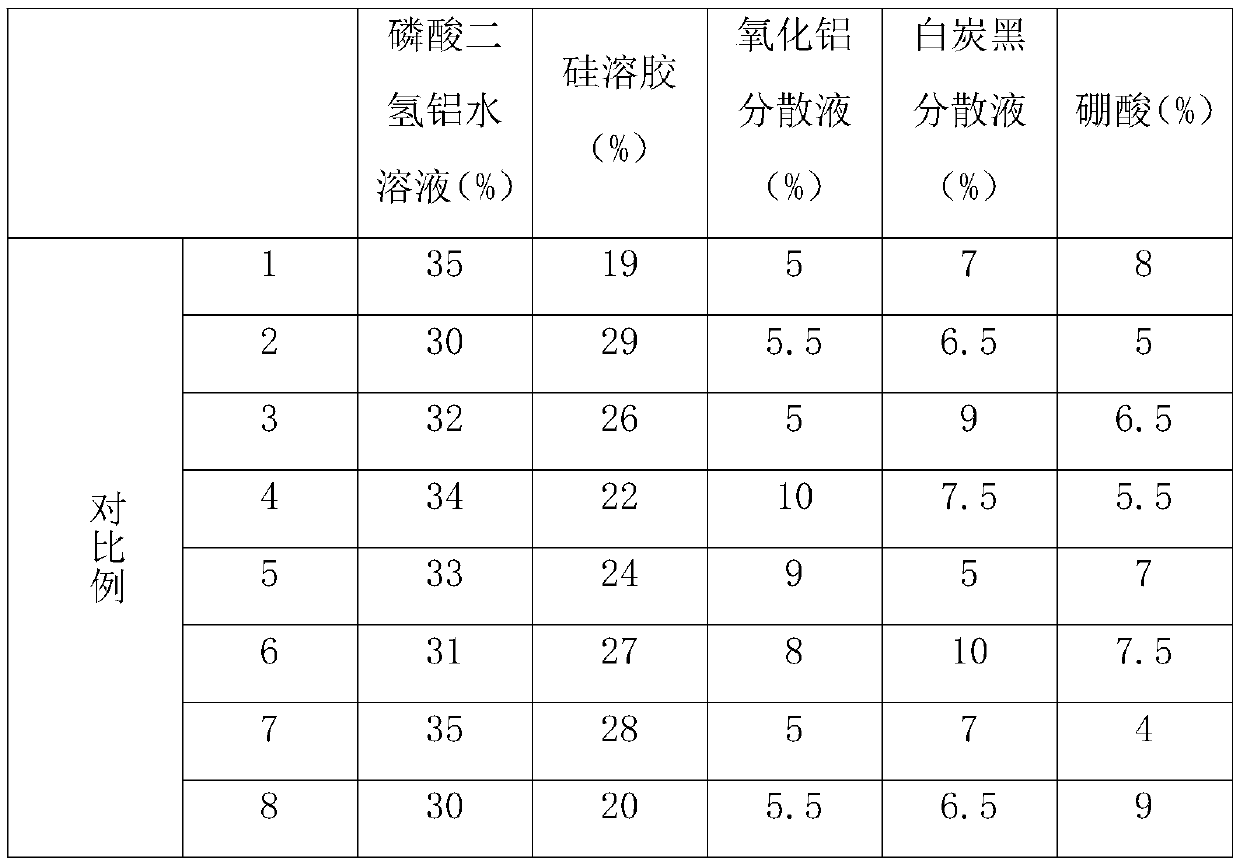

Environment-friendly insulating coating liquid as well as preparation method and application thereof

InactiveCN111171609AReduce pollutionGood environmental benefitsAnti-corrosive paintsPhosphateMoisture absorption

The invention provides an environment-friendly insulating coating liquid as well as a preparation method and application thereof, wherein the environment-friendly insulating coating liquid is preparedfrom the following raw materials based on the total mass: a phosphate aqueous solution, silica sol, boric acid, a compound dispersion liquid formed by at least one of B and Al, a white carbon black dispersion liquid and water. The environment-friendly insulating coating liquid disclosed by the invention does not contain harmful metal element chromium, so that the pollution to the surrounding environment is small, and the environment-friendly benefit is good; no organic component is contained, coating gaps are reduced after high-temperature curing, and the corrosion resistance is improved; andthe formed insulating coating has excellent adhesiveness, smooth and compact appearance, excellent lamination coefficient, good sliding property, moisture absorption resistance, heat resistance, sheet adhesion resistance and corrosion resistance.

Owner:上海迪升防腐新材料科技有限公司

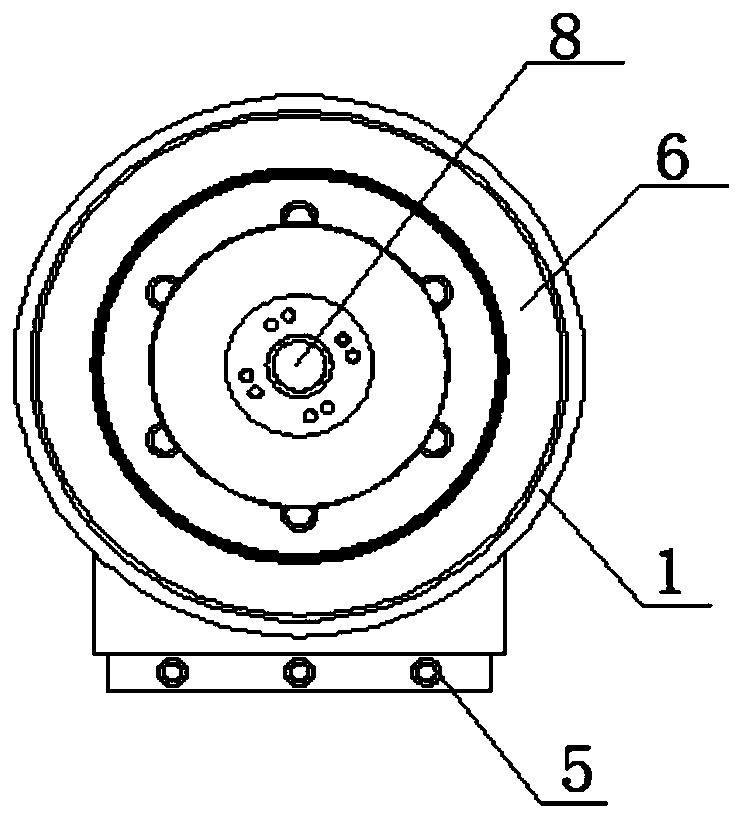

Integrated robot joint module

InactiveCN110666830ARealize an integrated solutionSave construction spaceJointsReduction driveLow voltage

The invention discloses an integrated robot joint module which comprises a joint shell and an end cover. A frameless motor is installed in the joint shell through an annular clamping groove, and a rotor is arranged in the frameless motor. One side of the frameless motor is provided with a low-voltage motor driver through fastening bolts. The other side of the frameless motor is provided with a bearing block through fastening bolts. A hollow input shaft is installed in the bearing block through a first bearing, and the hollow input shaft is sleeved with the rotor. One end of the hollow input shaft is fixedly connected with a harmonic reducer, and the harmonic reducer is located at the end of the joint shell. The output end of one side of the harmonic reducer is fixedly connected with a joint output disc, and a hollow output shaft is welded to one end of the joint output disc. One side of the low-voltage motor driver is provided with a second bearing through a round installation groove.According to the integrated robot joint module, the transmission structure is simplified, the internal structure is compact, installation and maintenance are more convenient, the dust-proof performance and heat dissipation performance are good, the working stability of the robot joint module is effectively guaranteed, and the service life is prolonged.

Owner:东莞市本润机器人科技股份有限公司

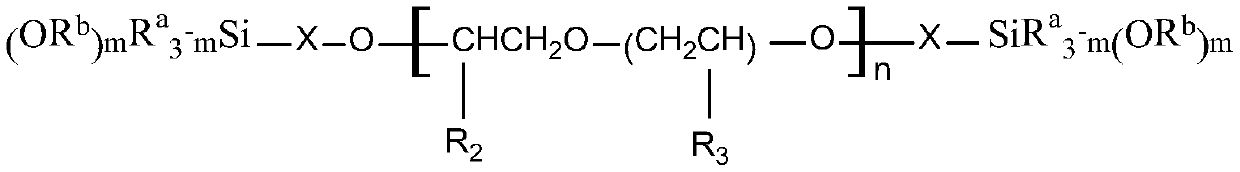

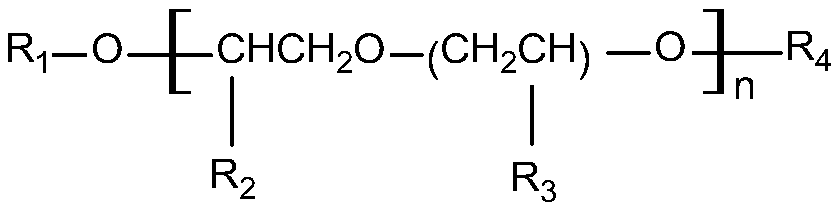

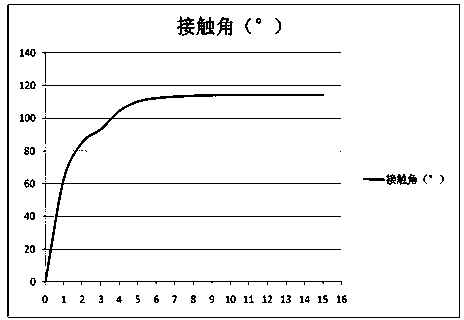

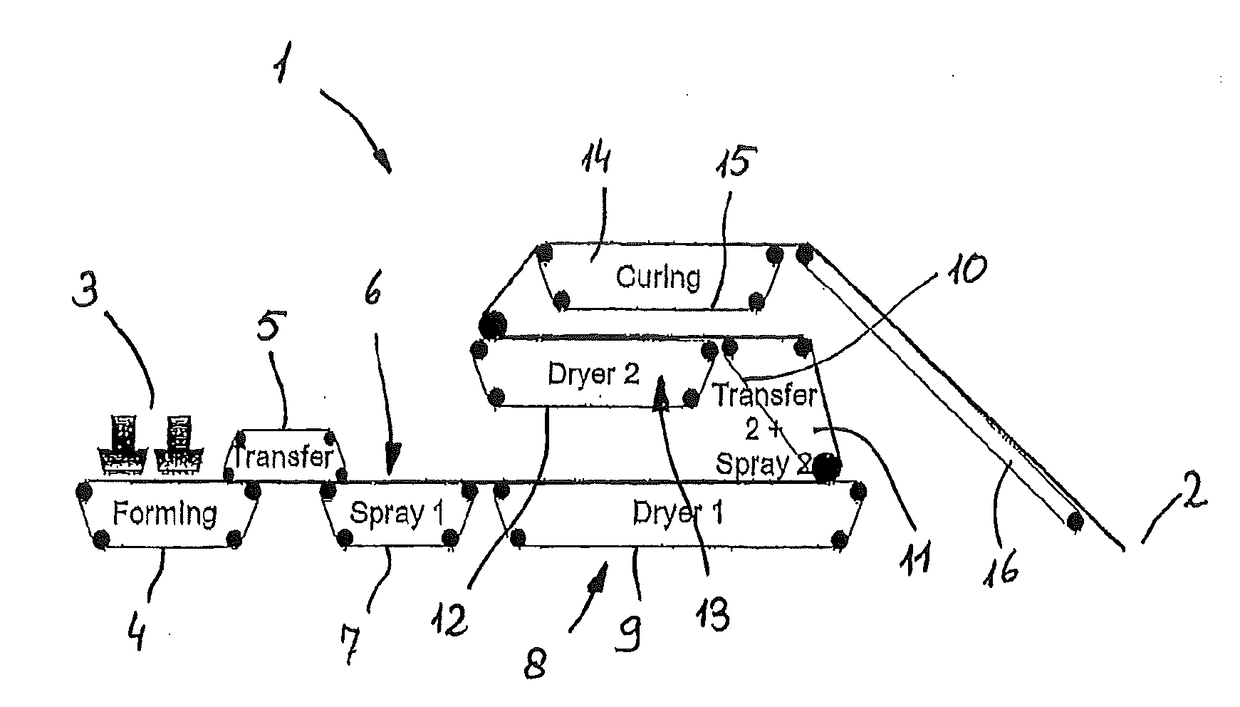

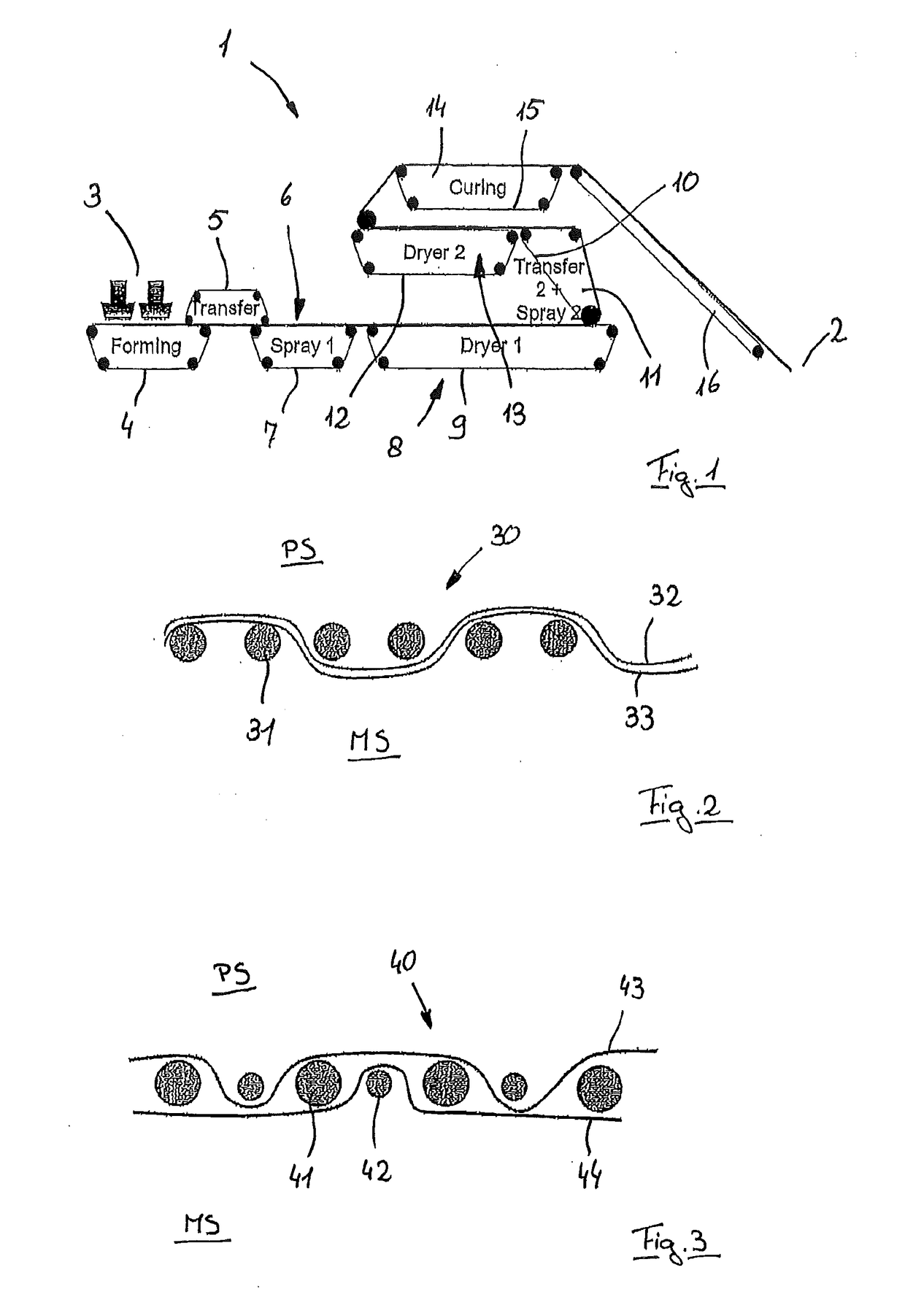

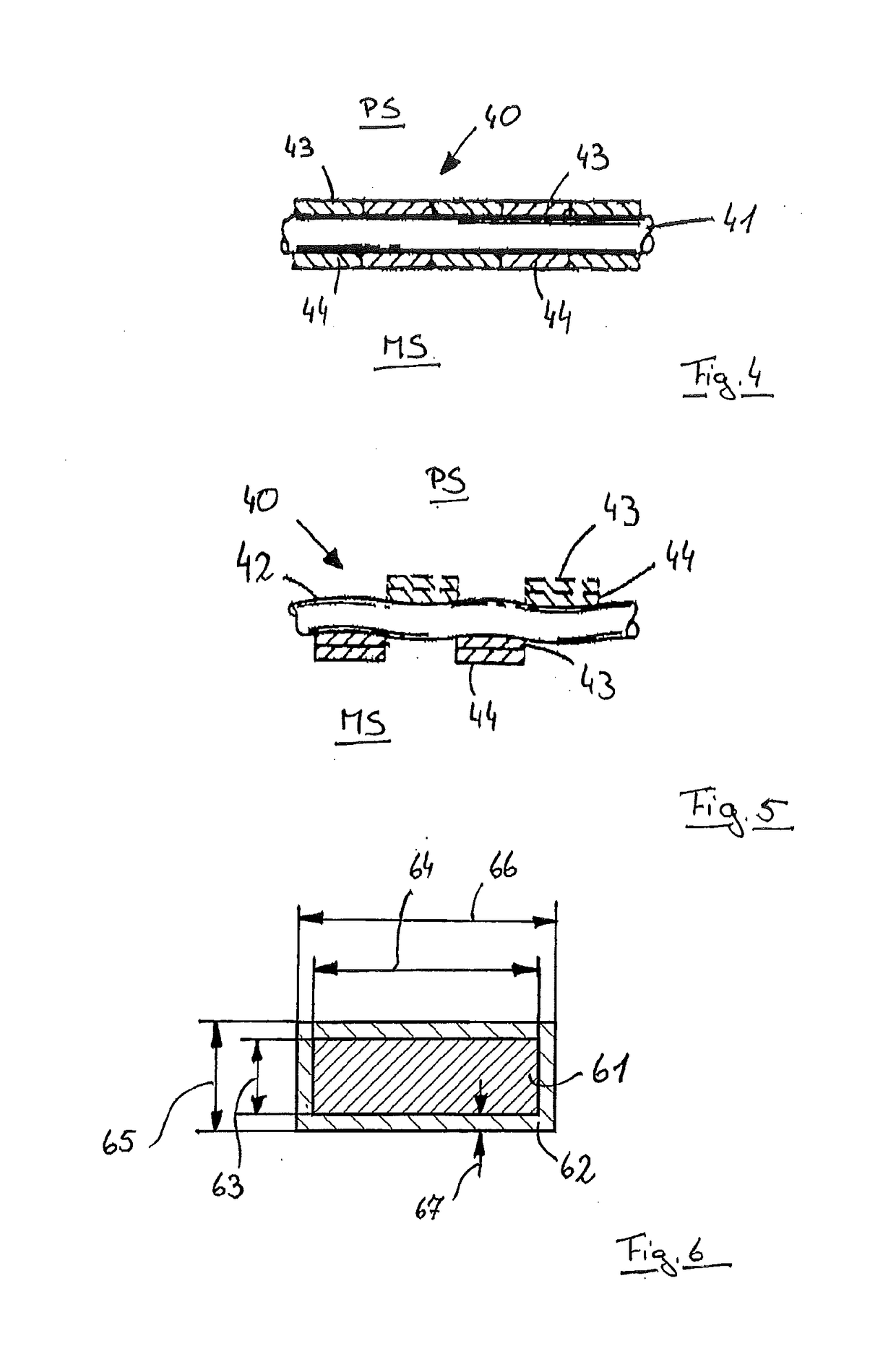

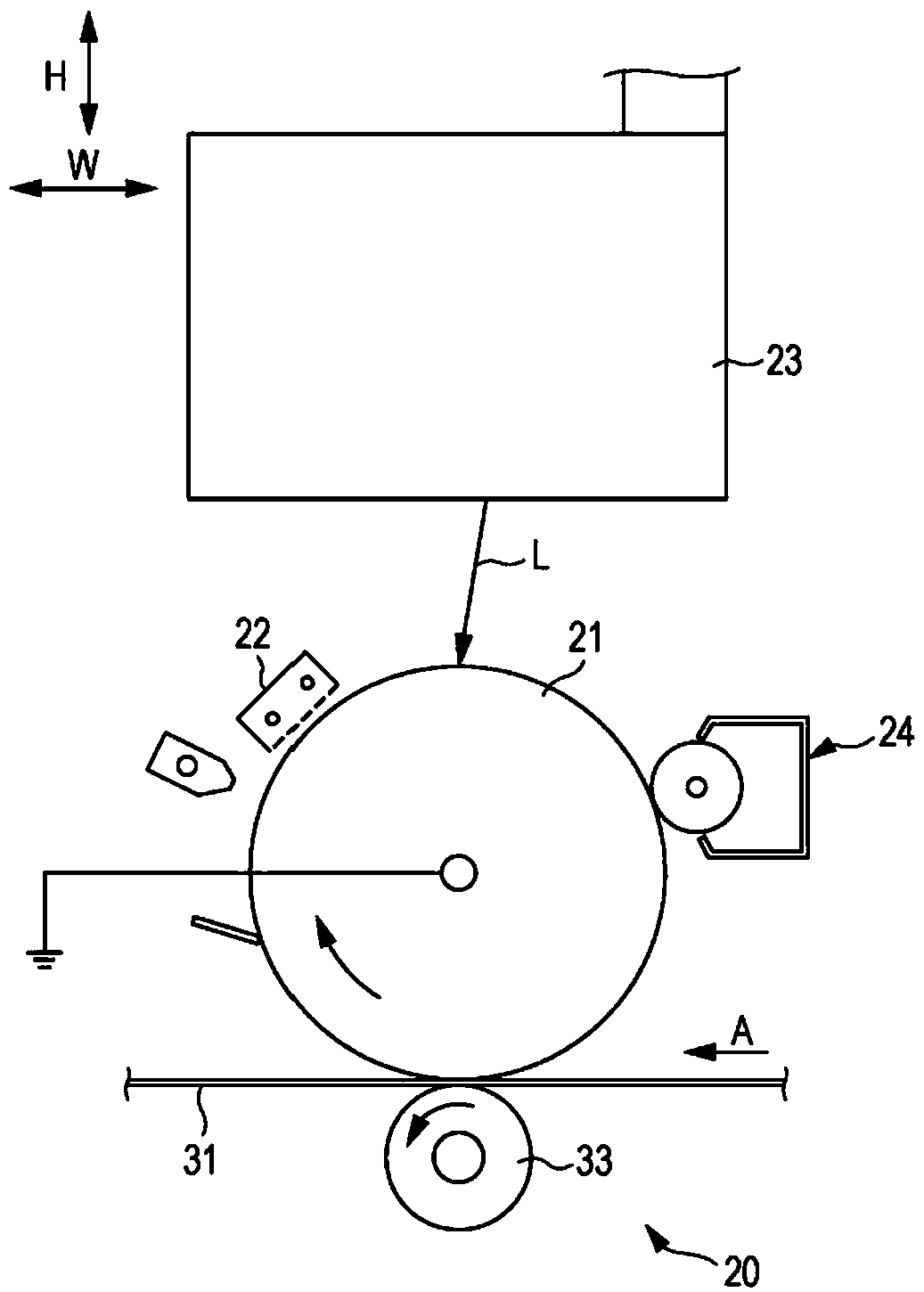

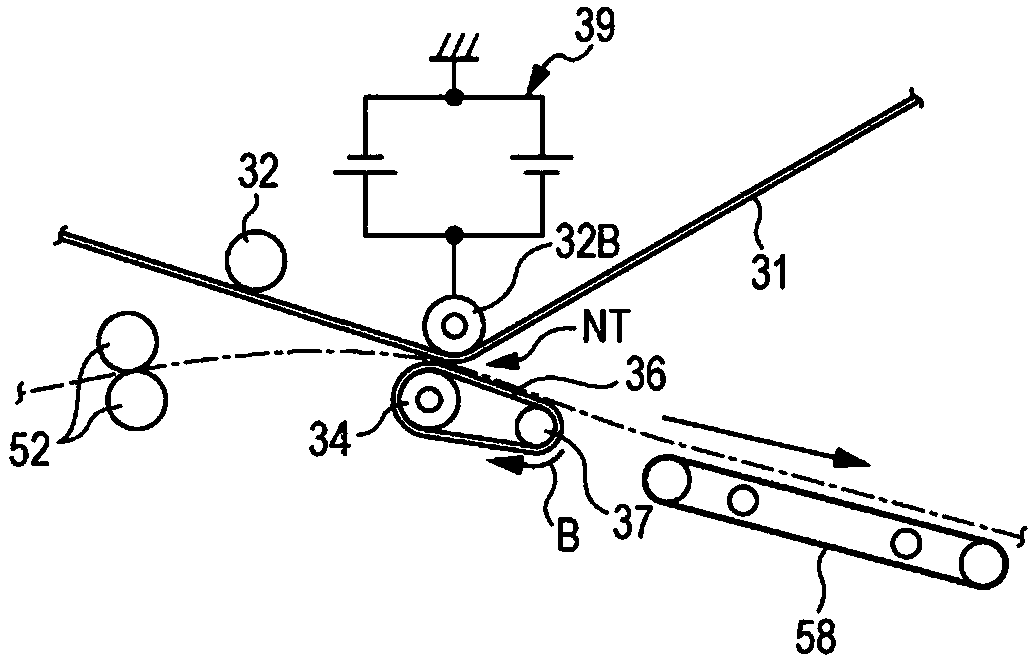

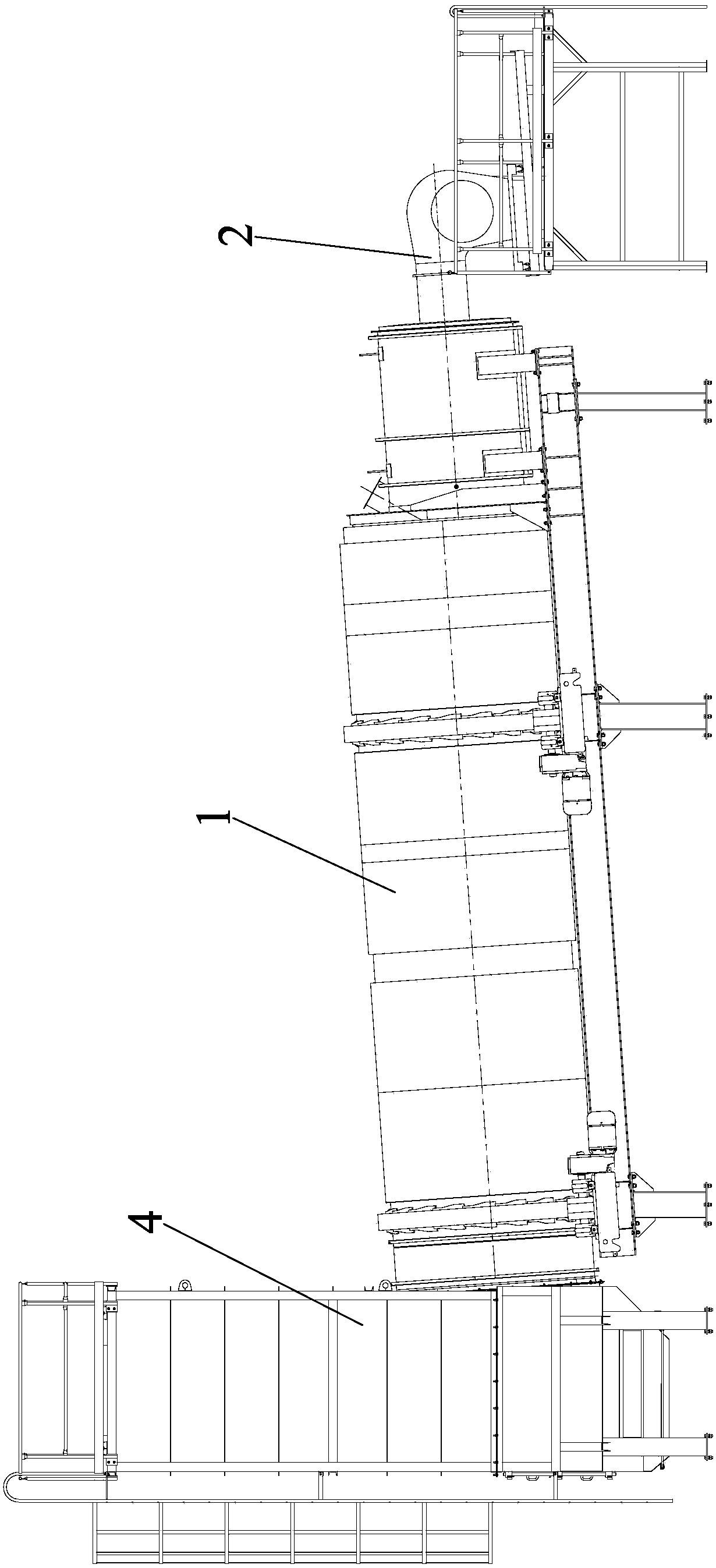

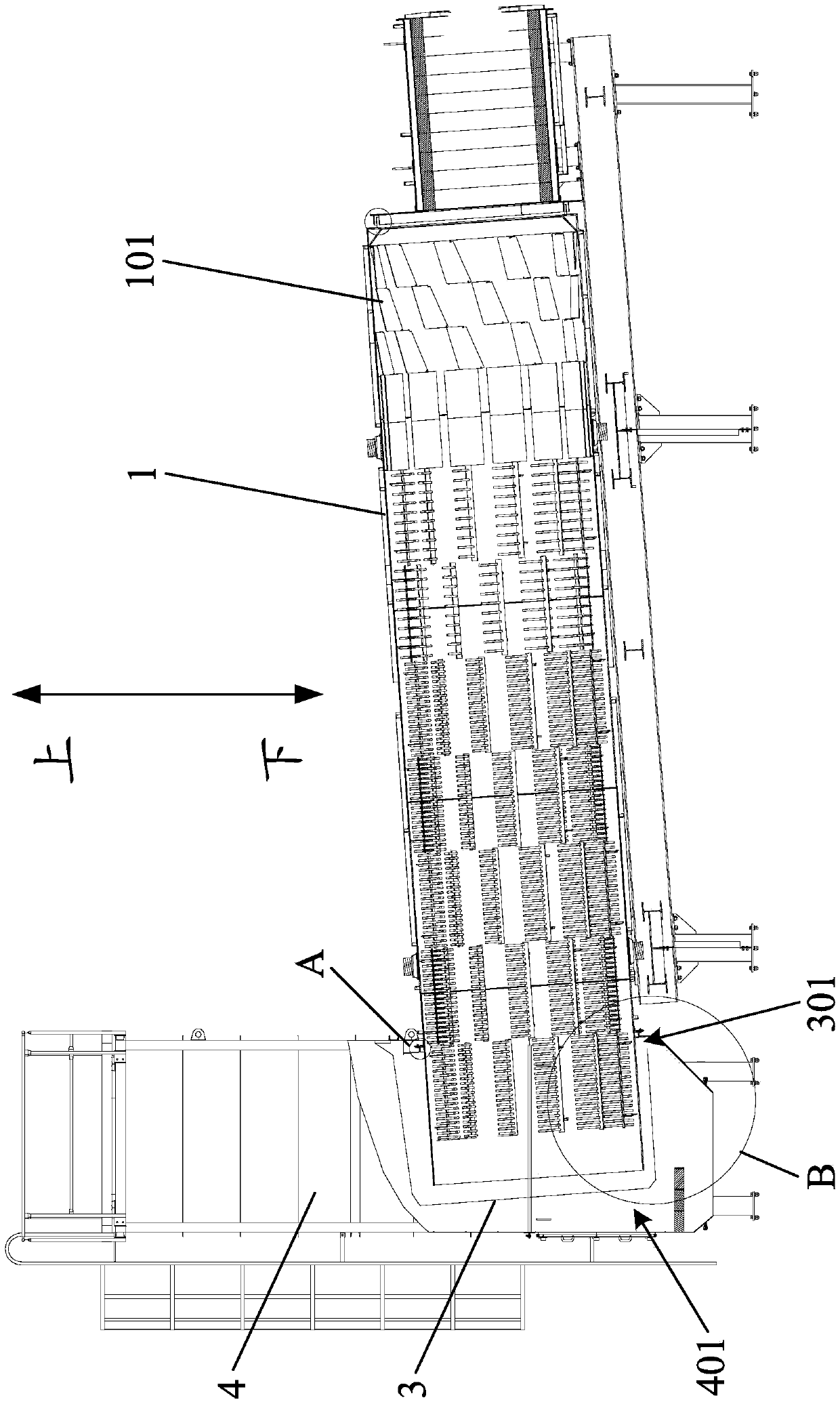

Industrial fabric, method for producing a nonwoven, and use of an industrial fabric

InactiveUS20170356104A1Trend downEasy to useWoven fabricsNon-woven fabricsPolymer scienceWilhelmy plate

An industrial fabric (30, 40, 45) is provided, in particular for transporting a nonwoven web while producing same, having a product side (PS), which is in contact with the nonwoven, and a machine side (MS), which is in contact with transport devices of a system (1) for producing the nonwoven. The fabric (30, 40, 45) has MD threads (32, 33, 43, 44, 48, 50), which run in the running direction of the nonwoven web, and CMD threads (31, 41, 42, 52), which run perpendicularly to the MD threads, said threads being woven together. At least two layers of MD threads (32, 33, 43, 44, 48, 50) are provided which are stacked one over the other in pairs and form product contact MD threads (32, 43, 50) and non-product contact MD threads (33, 44, 48). At least the material of each product contact MD thread (32, 43, 50) facing the product side (PS) forms a contact angle, measured according to the Wilhelmy plate method, of at least 80°, preferably at least 90°, more preferably at least 100°. In order to prevent the adhesion of threads to the fabric (30, 40, 45) and in order to reduce the air permeability, the fabric has a single layer of CMD threads (31, 41, 42, 52), and the cross-section of each product contact MD thread (32, 43, 50) has at least two regions, a first region of which is formed of the first material and a second region of which is formed of the second material. A substantial proportion, preferably a predominant proportion, of a tensile force acting on each product contact MD thread (32, 43, 50) can be transmitted from the second region, and the cross-section of the product contact MD threads (32, 43, 50) have a second region in the form of a core (61) and a first region in the form of a casing (62) which surrounds the core (61). The product MD threads (32, 43, 50) are preferably coextruded or are extruded in two successive steps. The MD threads (32, 33, 43, 44, 48, 50) have a flattened cross-section, preferably a rectangular cross-section, wherein a ratio of a height of the cross-section to a width of the cross-section preferably ranges from 1:1.2 to 1:10, preferably from 1:1.5 to 1:4. The invention further relates to a method for producing a nonwoven and to the use of an industrial fabric (30, 40, 45).

Owner:ASTENJOHNSON PGMBH

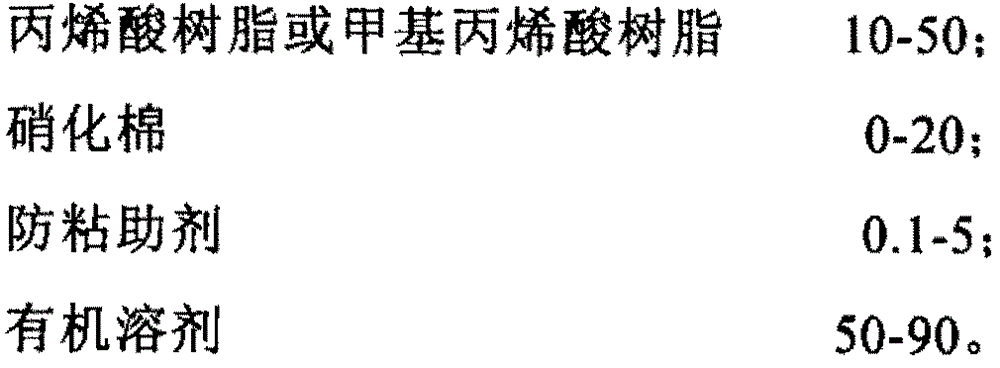

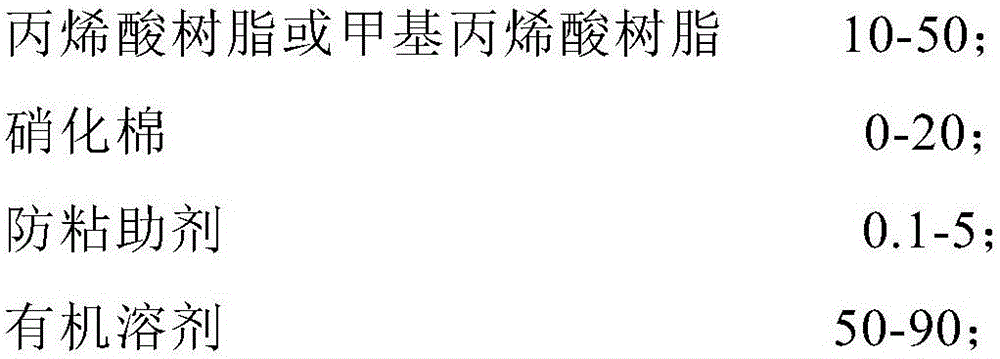

A kind of solvent type ABS glue for transfer printing and preparation method thereof

The invention relates to a solvent-based ABS adhesive for transfer printing and a preparation method thereof. The raw materials are composed of the following components and contents in parts by weight: acrylic resin or methacrylic resin 10-50, nitrocellulose 0-20, anti-adhesive aid 0.1 ‑5. Organic solvent 50‑90, add acrylic resin or methacrylic resin, nitrocellulose, anti-adhesive additives and solvent in the reactor according to the formula, and then under normal temperature and pressure, control the stirring so that the above raw materials are mixed evenly. A solvent-based ABS glue for transfer printing was prepared. Compared with the prior art, the invention has the advantages of simple production process, good adhesion to various ABS base materials, and low production cost.

Owner:上海华工艾马尔新材料有限公司

Neutral desizing, degreasing and dyeing one-bath auxiliaries for chemical fiber fabrics and preparation method thereof

ActiveCN103741513BSimple processEasy to operateFibre typesDry-cleaning apparatus for textilesFiberSulfonate

The invention relates to an additive for neutral desizing, oil removing and one-bath dyeing of chemical fiber fabrics and a preparation method thereof. Currently, no additives for neutral desizing, oil removing and one-bath dyeing of chemical fiber fabrics or preparation methods thereof are provided with excellent performance, energy saving, and consumption saving. The additive for neutral desizing, oil removing and one-bath dyeing of chemical fiber fabrics provided by the invention comprises 15-25 parts by weight of ANCconc, 15-30 parts of FMES, 5-15 parts of NPP, 5-10 parts of NA, 5-10 parts of penetrants, and 30-50 parts of water, wherein ANCconc is a surfactant with cleaning and anti-contamination functions, FMES is a sulfonate of fatty acid methyl ester ethoxylate, NPP is an oligomer remover, and NA is a multipurpose dispersant. The additive for neutral desizing, oil removing and one-bath dyeing of chemical fiber fabrics provided by the invention has excellent performance, allows the desizing, oil removing and one-bath dyeing processes of chemical fiber fabrics to be carried out under a neutral condition, and can realize direct dyeing without water washing, acid neutralization, or operating fluid discharge.

Owner:JIANGSU NEW REBA TECH CO LTD

Steel used for straight seam electric resistance welding petroleum casing and casing manufacturing method

ActiveCN101798654BHigh strengthImprove toughnessFurnace typesProcess efficiency improvementRoom temperatureWeld seam

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

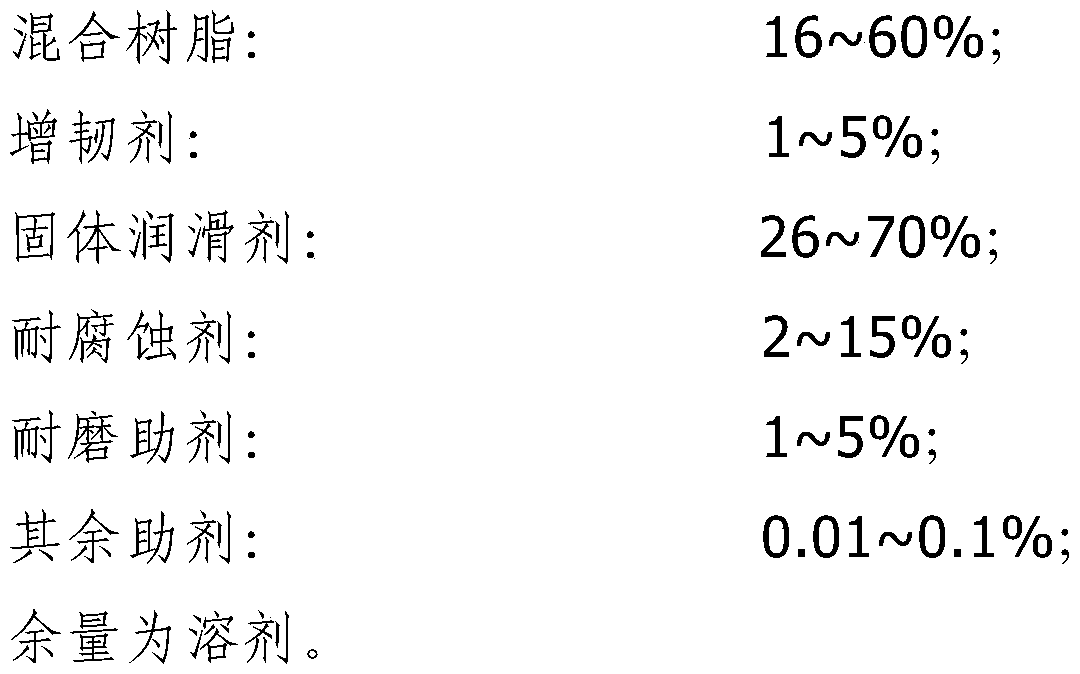

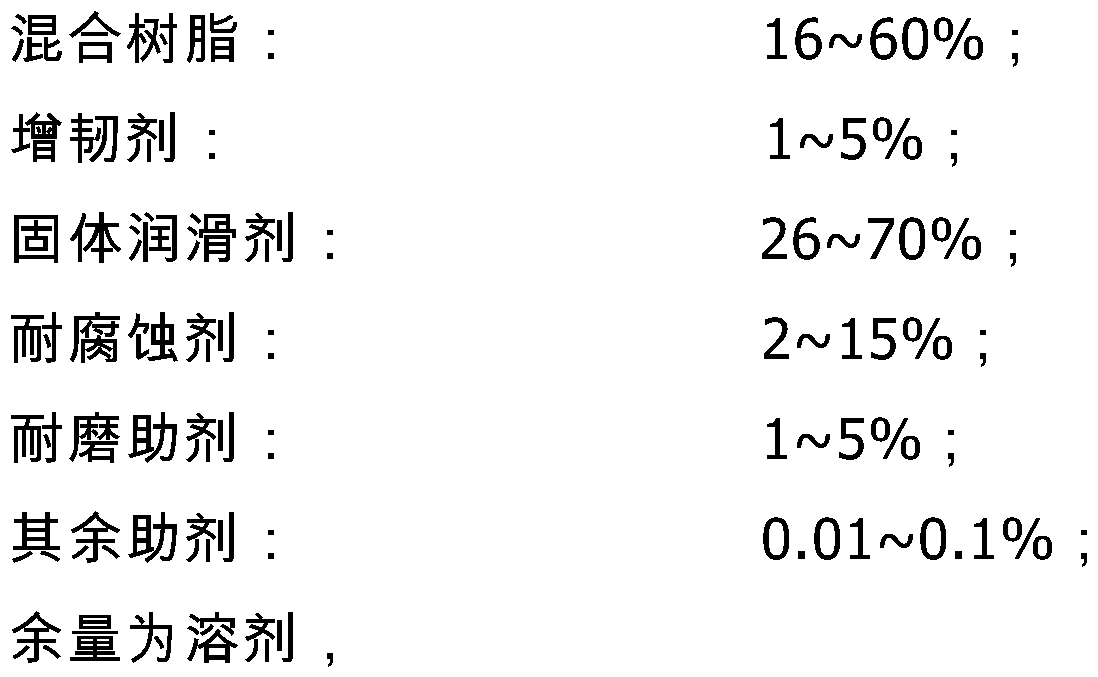

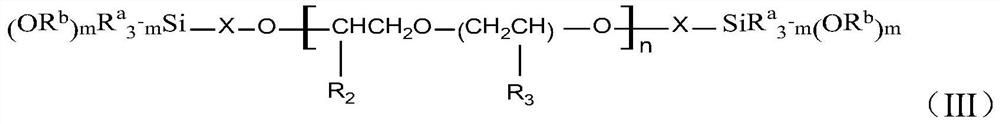

Anti-sticking solid lubricating coating and its preparation method and coating method

ActiveCN107286839BHigh bonding strengthGood anti-sticking propertiesSpecial surfacesEpoxy resin coatingsLubricantSurface coating

The invention discloses anti-gluing solid lubricating paint as well as a preparation method and an applying method thereof. The paint comprises the following ingredients in percentage by weight: 16-60% of mixed resin, 1-5% of a toughening agent, 26-70% of a solid lubricant, 2-15% of an anticorrosive etching reagent, 1-5% of a wear-resisting additive, 0.01-0.1% of other additives and the balance of a solvent. The paint, the preparation method and the applying method have the advantages that the thickness of a coating can be conveniently controlled according to a surface coating method of a joint of an oil casing; the process is simple; the operation is easy; the industrial implementation is realized conveniently.

Owner:BAOSHAN IRON & STEEL CO LTD

Anti-graffiti coating composition

The invention discloses a coating composition, which is a one-component coating composition or a two-component coating composition, comprising the following components: alkoxy silicone resin, hydroxyl silicone oil with dynamic viscosity below 1000mPa·s (25°C) , aminosilane and catalyst; Wherein, when the coating composition is a two-component coating composition, alkoxy silicone resin and hydroxyl silicone oil exist in different components. The coating composition of the invention mainly uses silicone, has excellent anti-graffiti performance and anti-sticking performance, and can realize zero solvent.

Owner:WACKER CHEM GMBH

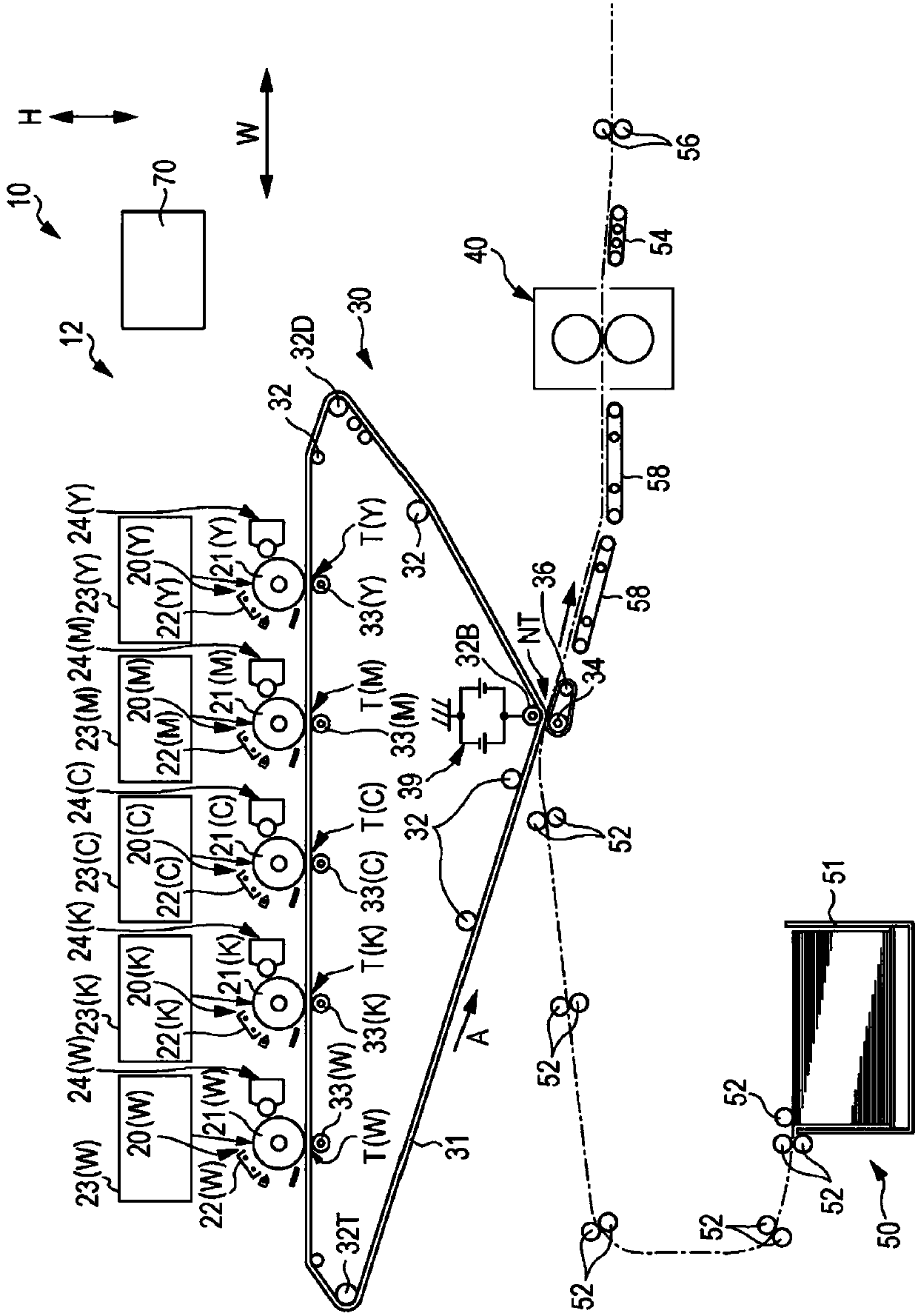

Resin film and image forming apparatus

PendingCN109557783ASuppression of scatteringDeletion of suppressionElectrographic process apparatusCommon logarithmImage formation

The invention provides a resin film. The resin film on which an image containing white toner or metallic toner is formed, and the common logarithm of surface resistivity of both sides of the resin film exceeds 11.2 (log Omega / sq) And providing a resin film that suppresses scattering of the toner image to the rear side of a toner image formed using white toner or metallic toner in comparison with the above. An image is formed on the surface of a white toner or a metallic toner containing a metallic pigment, and an image receiving layer on which an image is formed in contact with a resin substrate and one surface of the resin substrate, and a resin substrate A resistance adjusting layer in contact with the other surface of the film, and at least one of the image receiving layer and the resistance adjusting layer has a common logarithmic value of surface resistivity at a temperature of 20 DEG C. and a humidity of 10% RH of 11.2 (log Omega / sq) or less Is a resin film.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Harmonic reducer surface machining treatment method

InactiveCN110512251AAvoid disadvantagesPlay the role of crack preventionAnodisationVacuum evaporation coatingMicro arc oxidationEngineering

The invention discloses a harmonic reducer surface machining treatment method. The treatment method comprises the following specific steps: (1) technicist writes production machining procedures, masters machining treatment attentions, and prepare machining materials and equipment; (2) flexible wheels are put in an ultrasonic cleaner; and clear water and sodium hydroxide solution are fed for quickcleaning by using ultrasonic waves; (3) the flexible wheels cleaned in the step (2) are quickly dried in warm air; oil stains and rust on the surfaces of basal bodies are removed; and sand is blasted;(4) the basal bodies of the flexible wheels treated in the step (3) are clamped on electrodes and dipped in electrolyte solution; and under the condition of constant current, the voltage is slowly increased to grow microarc oxidation ceramic layers on the surfaces of the basal bodies of the flexible wheels; and (5) the flexible wheels are put in a vacuum chamber of microarc ion treatment equipment. The harmonic reducer surface machining treatment method is stable, reliable, simple in equipment, convenient to operate, high in practicability and suitable for wide popularization and application.

Owner:东莞市本润机器人科技股份有限公司

Recycled Bitumen Heating Plant

The invention provides a recycled asphalt heating device which comprises a rotary drum, a heater and an air guide and reflux device, wherein the rotary drum is provided with a material feeding end and a material discharging end; the heater is connected with the material feeding end and is used for injecting high-temperature gas into the rotary drum; the air guide and reflux device is arranged at the material discharging end of the rotary drum and is used for heating the outer wall of the material discharging end through the gas flowing out of the material discharging end. According to the recycled asphalt heating device provided by the invention, the air guide and reflux device is arranged at the material discharging end of the rotary drum, so that the air guide and reflux device can be used for guiding the gas discharged from the material discharging end to the outer side wall of the material discharging end of the rotary drum, to enable the gas discharged from the material discharging end to heat a material in the rotary drum again, and temperature reduction of the material discharging end of the rotary drum can be slowed down. Therefore, the phenomenon that the material is attached to the inner wall of the material discharging end of the rotary drum and a material raising device due to extremely low temperature is avoided, the forming quality of a material curtain is effectively enhanced, the heating efficiency of a product is improved, the cleaning period of the rotary drum is correspondingly prolonged, and continuous production of the product is guaranteed.

Owner:HUNAN SANY ROAD MACHINERY

Steel for expandable casing for oil well and manufacturing method thereof

ActiveCN101812631BPerformanceFine grainTemperature control deviceFurnace typesNumerical controlEngineering

The invention discloses steel for an expandable casing for an oil well and a manufacturing method thereof, and the manufacturing method is applied to preparing the expandable casing for the oil well for petroleum and gas industrial oil. The steel alloy material of the expandable casing for the oil well comprises the following components in percentage by weight: 0.08 to 0.2 percent of C, 1 to 2 percent of Mn, 0.15 to 0.35 percent of Si, 0.02 to 0.06 percent of Al, less than or equal to 0.01 percent of P, less than or equal to 0.05 percent of S, less than or equal to 0.08 percent of N, 0.001 to0.005 percent of Ca, and the balance of Fe. The method for preparing the expandable casing for the oil well comprises the following steps of: preparing hot rolled steel coils; producing straight seamresistance welded steel pipes by using the hot rolled steel coils; normalizing welding lines after welding; and finally, cutting into welded steel pipes, and machining API standard threads or specialthreads at two ends of each welded steel pipe by using a numerical control machine. The steel for the expandable casing for the oil well has the advantages of excellent comprehensive performance suchas expansion deformation capacity, intensity, toughness, and the like, no defect of the welding lines and uniform and consistent performance with base metals.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High hydrophobic anti pasting poster paint

ActiveCN101550303BImprove surface hydrophobicityStrong surface anti-adhesionCoatingsHigh surfaceHydrophobic surfaces

A high hydrophobic anti pasting poster paint, which is characterized in that the coating includes following components, weight parts of each is: water 20-40, thickening agents 0.1-3, AMP 95 0.1-0.5, dispersant 0.2-2, defoamer 0.1-0.5, color filling agent 20-50, hydrophobic surface anti pasting agent 0.1-0.5, emulsion 10-40, film-forming additive 0-2, preservative agent 0.1-1. the color filling agent is composed of diatomite or calcium carbonate matching with quartz powder and titanium dioxide and mixing, wherein the weight ratio of diatomite or calcium carbonate: quartz powder: titanium dioxide is 1: 0.5-5.5: 1-5. The present invention is provided with characteristics of high surface hydrophobic nature and surface anti pasting ability after film-forming, not easy to doodle or covered by sewerage or other coatings, and not easy to be pasted by common advertisement sticker with gum in the back, stable property, simple production process and convenient for construction.

Owner:GUANGDONG HUARUN PAINT CO LTD

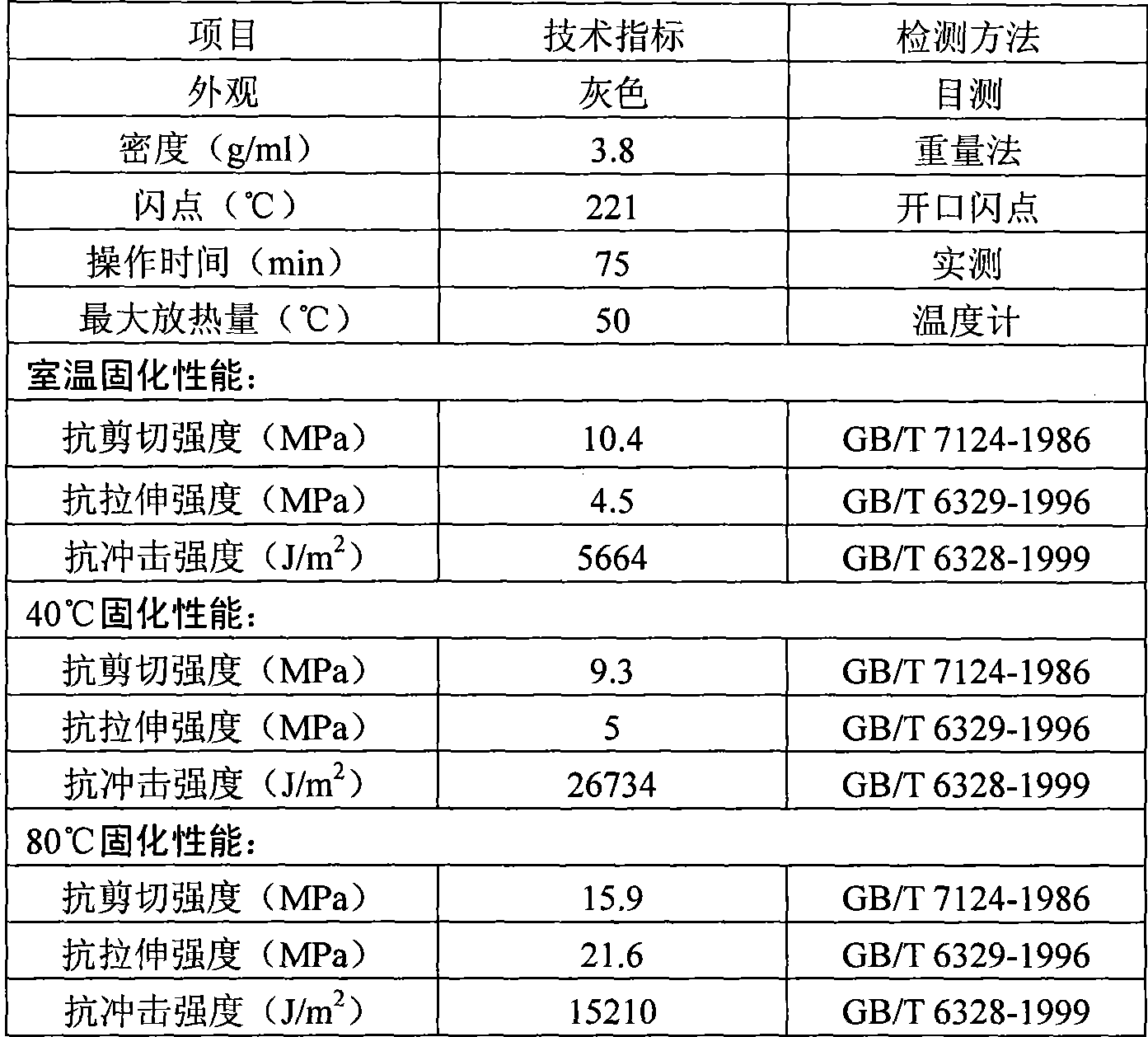

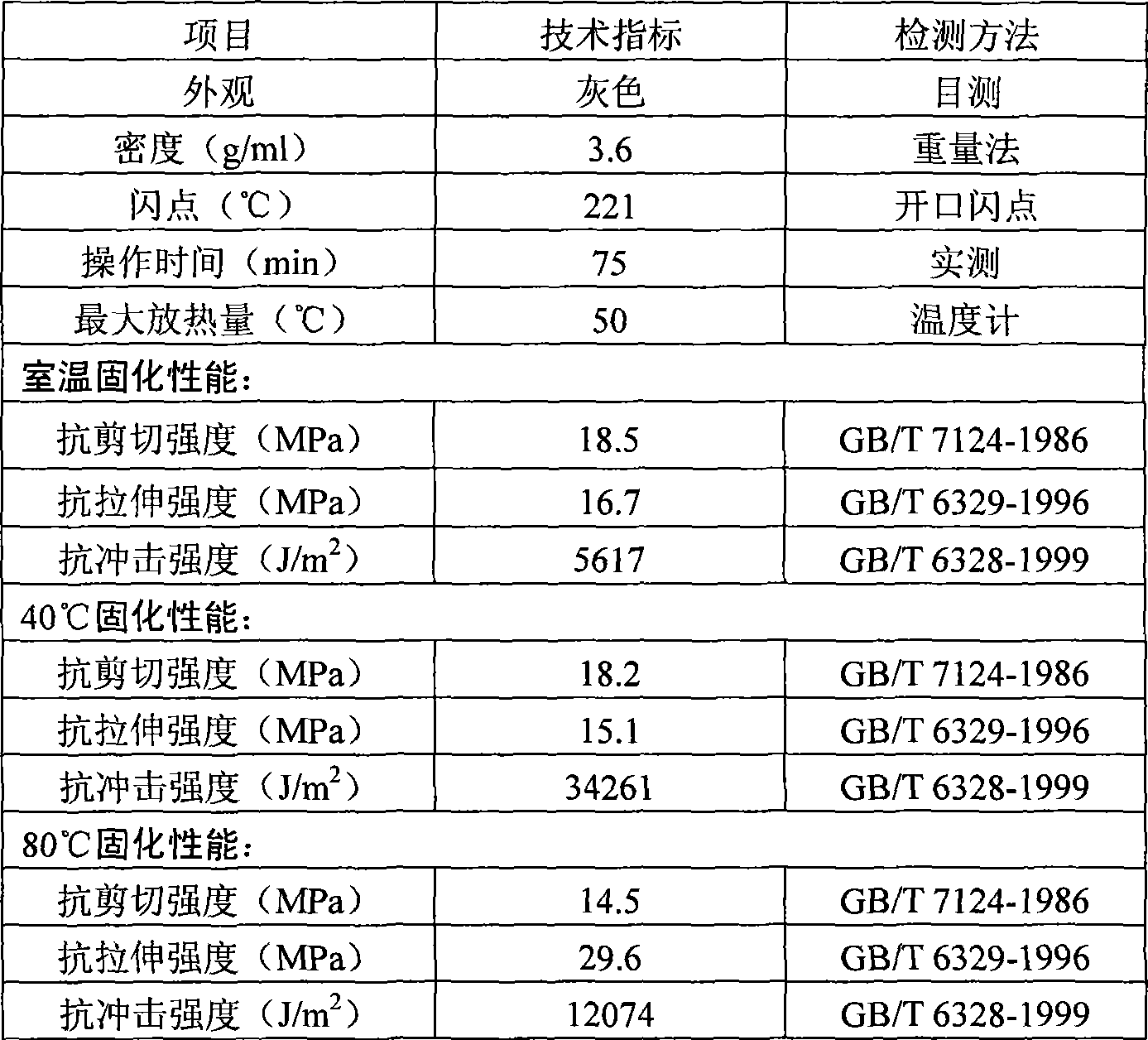

Highly hydrolysis-resistant and anti-stick adhesive for aluminum-plastic composite labels and its preparation

ActiveCN109337634BSuitable for bondingHigh bonding strengthPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a highly hydrolysis-resistant and anti-adhesive adhesive for aluminum-plastic composite labels and its preparation; the adhesive is composed of A component and B component, and the A component includes polyester poly Alcohol, modified epoxy resin, hydroxyl acrylic resin, chain extender, catalyst, solvent; the B component includes initiator, isocyanate curing agent. The adhesive of the present invention is particularly suitable for the bonding of aluminum foil or aluminum-plated layer and PET film; it has high bonding strength to aluminum-plastic composite materials, has good acid and alkali resistance, and damp heat aging resistance, and uses the adhesive of the present invention Adhesive, adhesive layer and adhesive layer, adhesive layer and aluminum all have good anti-sticking properties; after the aluminum-plastic composite label etching process, the sample roll will not damage the label due to sticking back.

Owner:SHANGHAI WEIKAI CHEM +2

Anti-sticking three-stage end face metal seal titanium alloy pipe thread joint

ActiveCN103628827BImproves sealing reliabilityLow contact pressureDrilling rodsDrilling casingsButtressThree stage

The invention relates to a threaded structure for connection of a well completion production tubular column of the petroleum and gas industry, in particular to an anti-bonding three-stage end surface metal sealing threaded connector for a titanium alloy pipe. The anti-bonding three-stage end surface metal sealing threaded connector for the titanium alloy pipe comprises an oil casing collar and an oil casing end, wherein the oil casing collar is provided with an API buttress inner thread, the oil casing end is provided with a buttress outer thread matched with the API buttress inner thread, a tool withdrawal groove is formed in one end of the API buttress inner thread and is sequentially connected with an arc surface I and an arc surface II through chamfer transition, the arc surface II is connected with a negative angle torque lifting shoulder I through chamfer transition, a conical surface, a cylindrical surface and a negative angle torque lifting shoulder II are arranged at one end of the buttress outer thread, the conical surface and the cylindrical surface sequentially correspond to the arc surface I and the arc surface II, the negative angle torque lifting shoulder II corresponds to the negative angle torque lifting shoulder I, and after the oil casing collar is matched with the oil casing end in a threaded mode, interference sealing is carried out on metal through a first-stage sealing structure of the arc surface I on the conical surface, a second-stage sealing structure of the arc surface II on the cylindrical surface and third-stage metal of the sealing structure of the negative angle torque lifting shoulders. The anti-bonding three-stage end surface metal sealing threaded connector for the titanium alloy pipe improves the air sealing reliability, and has good anti-bonding performance.

Owner:忠世高新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com