A kind of solvent type ABS glue for transfer printing and preparation method thereof

An ABS glue and solvent-based technology, which is applied in the field of solvent-based ABS glue for transfer printing and its preparation, can solve the problems of the customer's substrate that cannot be transferred normally, the ABS glue has narrow adaptability, and the price is high, so as to improve the ease of use. Adhesion and anti-sticking properties are good, and the effect of enhancing slipperiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

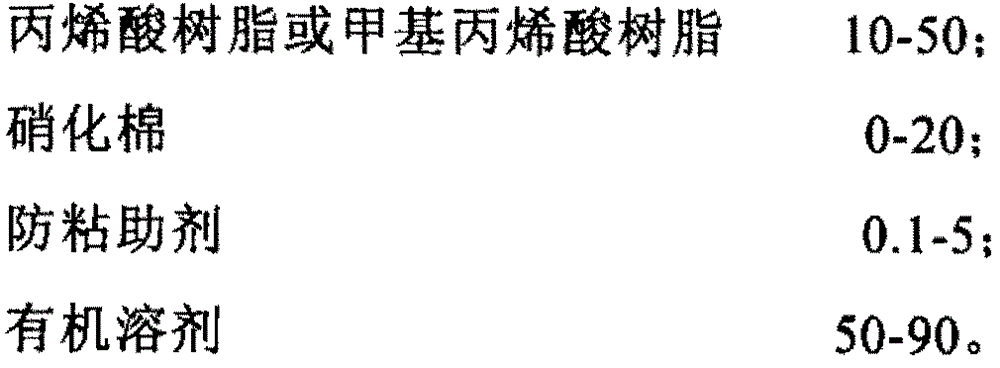

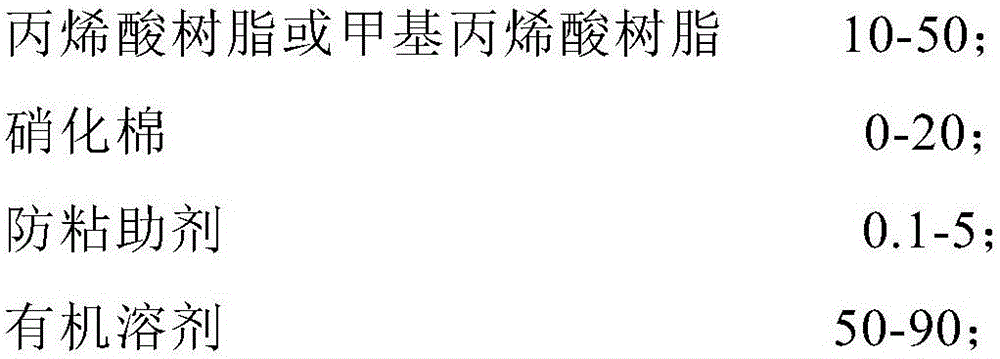

[0023] Add 20 parts of acrylic resin solution to the batching kettle in turn, you can choose ALMATEX L1093; add 10 parts of NC solution, you can choose NC with a viscosity of 1 / 8 second; 1 part of anti-adhesive additive, you can choose W'Add1500; 69 parts Toluene; then start the mixer at a speed of 5000 rpm, and stir for 30 minutes. The glue can be properly diluted with toluene according to the viscosity requirements during use.

Embodiment 2

[0025] Add 25 parts of acrylic resin solution to the batching kettle in turn, you can choose Inalic T8238 type; add 5.5 parts of NC solution, you can use NC with a viscosity of 1 / 2 second; add 0.5 parts of anti-adhesive additive, you can choose 818S solvent wax slurry; 40 parts of toluene, 29 parts of methyl ethyl ketone; then start the mixer at a speed of 6000 rpm, and stir for 20 minutes. The glue can be properly diluted with toluene according to the viscosity requirements during use.

Embodiment 3

[0027] Add 28.5 parts of acrylic resin solution to the batching kettle in turn, you can choose SN-9700; 1.5 parts of anti-adhesive additive, you can choose A-960 silicone smoothing and leveling agent; 35 parts of toluene, 35 parts of ethyl acetate and then start the mixer , the rotation speed is 4000 rpm, just stir for 40 minutes, the glue can be properly diluted with toluene according to the viscosity requirement during use.

[0028] The ABS glue prepared by the above method is used for gravure coating, the mesh line of the version roller is 175 lines, the glue viscosity is 20 seconds, and the coating machine speed is 60m / min. After coating, the transfer film is ironed on ABS material, PC material, PMMA material workpiece , The temperature of the hot stamping machine is 230 degrees, the pressure of the rubber wheel is moderate, and the linear speed of the rubber wheel is 80cm / min. After the transfer, the workpiece is tested for glue adhesion with 3M detection tape, and no ink ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com