Resin film and image forming apparatus

A technology of resin film and image, which is applied in the direction of electrical recording technology using charge graphics, equipment and instruments using electrical recording technology using charge graphics, etc., can solve problems such as scattering, achieve improved covering performance, excellent anti-sticking performance, and inhibit missing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described below. These descriptions and examples illustrate embodiments and do not limit the scope of the invention.

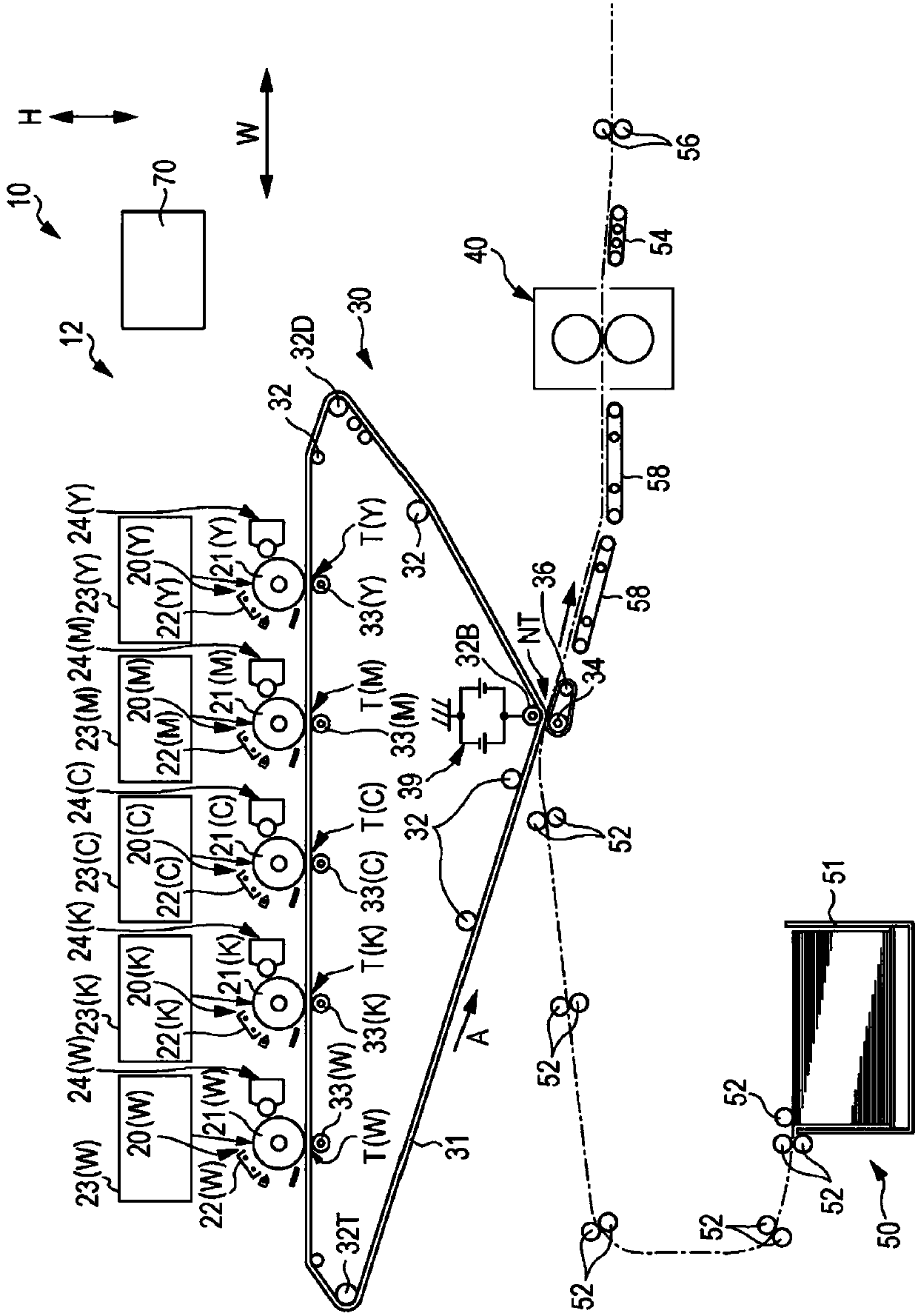

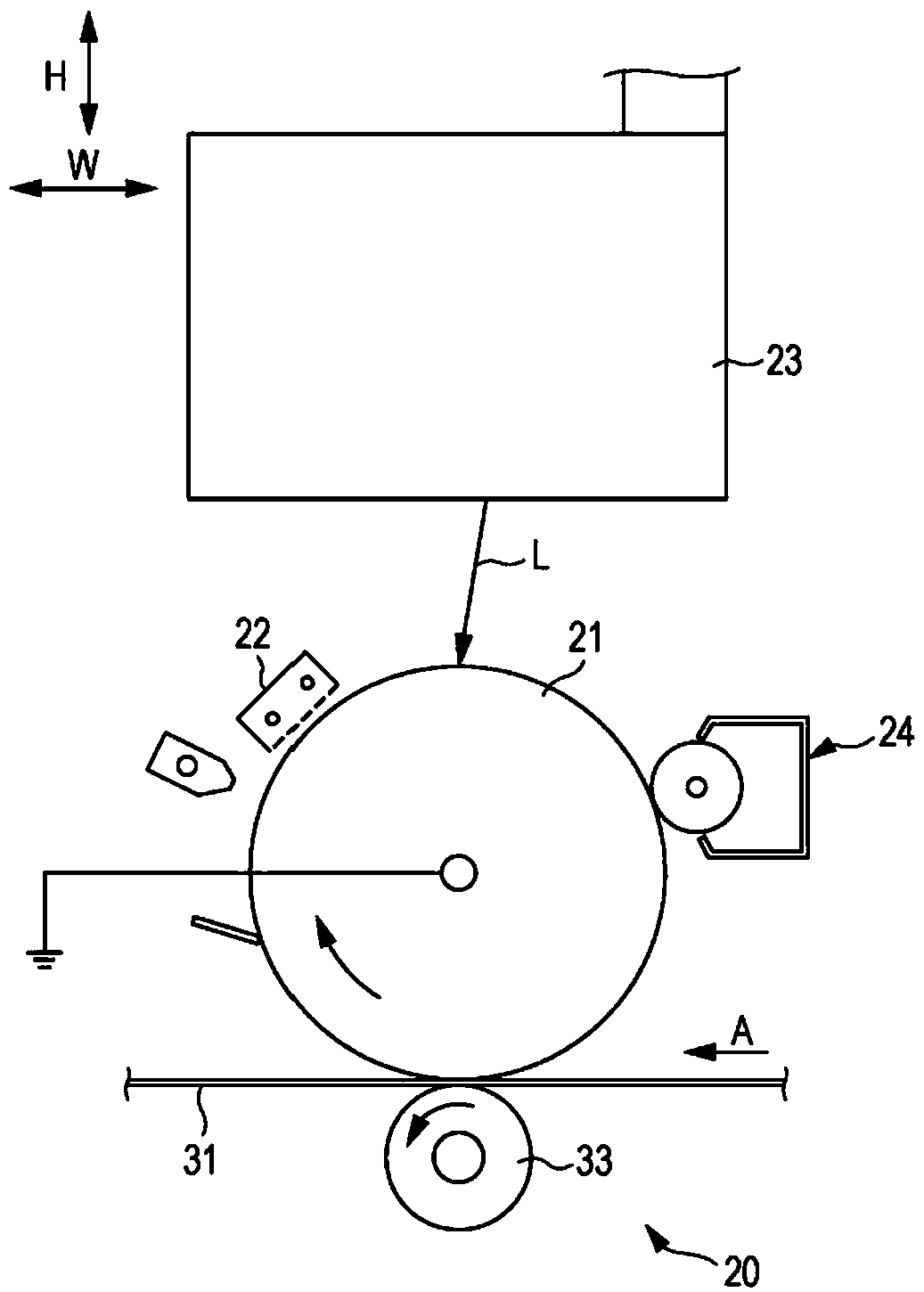

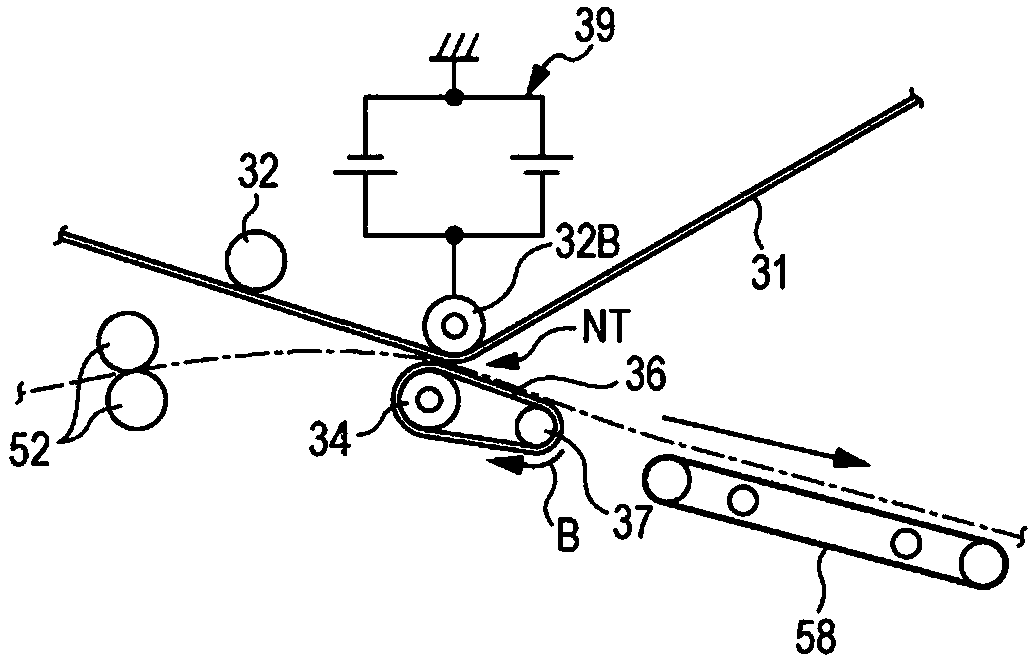

[0033] "Structure of this embodiment"

[0034] The film according to this embodiment includes an image of a white toner or a metallic toner containing a metallic pigment formed on its surface, and is characterized in that it includes: a resin substrate; and an image is formed in contact with one surface of the resin substrate. and the resistance adjustment layer in contact with the other face of the resin substrate, the common logarithm value of the surface resistivity of at least one of the image reception layer and the resistance adjustment layer at a temperature of 20° C. and a humidity of 10% RH is 11.2 (logΩ / sq) or less.

[0035] Conventionally, transparent resin films have been used in various ways such as forming images on the surface and processing them into product packaging and POP advertisements. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com