Highly hydrolysis-resistant and anti-stick adhesive for aluminum-plastic composite labels and its preparation

An aluminum-plastic compounding and adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of insufficient bonding strength, slow curing speed, sticky back and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

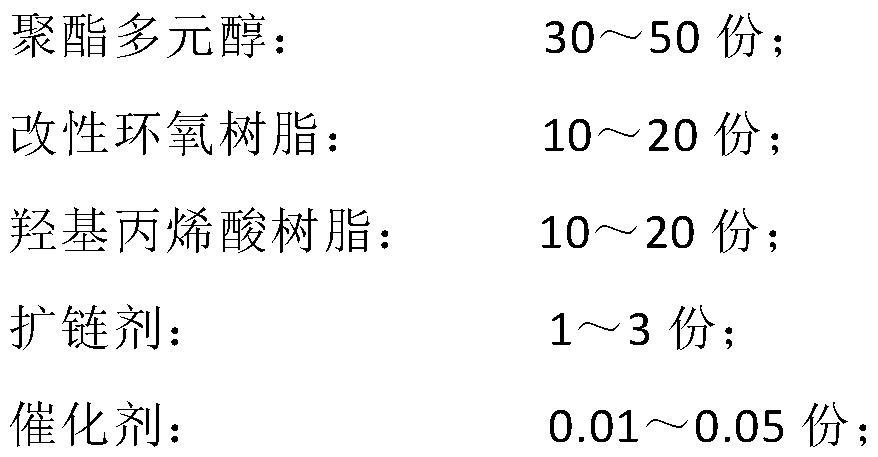

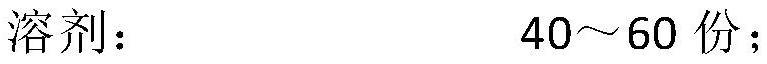

Method used

Image

Examples

Embodiment 1

[0032] The present embodiment relates to a preparation method of an anti-stick back aluminum-plastic composite label adhesive, comprising the following process steps:

[0033] (1) first put all solvent, namely 49.99 kilograms of ethyl acetate into the reactor, and be heated to about 40 ℃ and stir;

[0034] (2) keep stirring and put 40 kilograms of side vinyl polyester polyols, 10 kilograms of modified epoxy resins, and 10 kilograms of hydroxy acrylic resins into the reactor successively, and stir about 1 hour;

[0035] (3) 0.01 kilogram of bismuth-zinc composite catalyst and 2 kilograms of chain extender (trimethylolpropane) are slowly dropped into the reactor after being mixed evenly;

[0036] (4) After all solids are dissolved and mixed uniformly, measure the solid content and adjust to the theoretical value;

[0037] (5) Stir slowly for about 1 hour, cool, weigh and pack to obtain component A;

[0038] (6) Mix 2 g of azobisisobutyronitrile with 40 g of polyisocyanate curi...

Embodiment 2

[0041] The present embodiment relates to a preparation method of an anti-stick back aluminum-plastic composite label adhesive, comprising the following process steps:

[0042] (1) first put all solvents, namely 39.95 kilograms of ethyl acetate, 10 kilograms of butanone into the reactor, and be heated to about 50 ℃ and stir;

[0043] (2) keep stirring and put 40 kilograms of side propylene polyester polyols, 10 kilograms of modified epoxy resins, and 10 kilograms of hydroxy acrylic resins into the reactor successively, and stir about 1 hour;

[0044] (3) 0.05 kilogram of bismuth-zinc composite catalyst and 1 kilogram of chain extender (triethanolamine) are slowly dropped into the reactor after being mixed evenly;

[0045] (4) After all solids are dissolved and mixed uniformly, measure the solid content and adjust to the theoretical value;

[0046] (5) Stir slowly for about 1 hour, cool, weigh and pack.

[0047] (6) Mix 2 g of azobisisobutyronitrile with 40 g of polyisocyanate...

Embodiment 3

[0050] The present embodiment relates to a preparation method of an anti-stick back aluminum-plastic composite label adhesive, comprising the following process steps:

[0051] (1) first put all solvent, namely 47.97 kilograms of butyl acetate into the reactor, and be heated to about 50 ℃ and stir;

[0052] (2) keep stirring and drop 40 kilograms of side styrene-based polyester polyols, 10 kilograms of modified epoxy resins, and 20 kilograms of hydroxy acrylic resins into the reactor successively, and stir about 1 hour;

[0053] (3) 0.04 kilograms of bismuth-zinc composite catalyst and 3 kilograms of chain extenders (dimethylthiotoluenediamine) are slowly dropped into the reactor after being mixed evenly;

[0054] (4) After all solids are dissolved and mixed uniformly, measure the solid content and adjust to the theoretical value;

[0055] (5) Stir slowly for about 1 hour, cool, weigh and pack.

[0056] (6) Mix 2 g of azobisisobutyronitrile with 40 g of polyisocyanate curing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com