Durable scrawling-preventive anti-paste paint capable of being repeatedly coated, and preparation method thereof

An anti-graffiti, durable technology, applied in the direction of coating, which can solve the problems of reduced overcoatability, high cost, poor coating durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

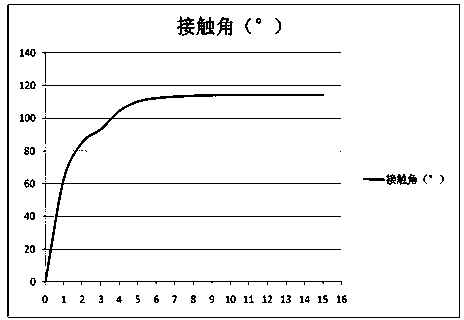

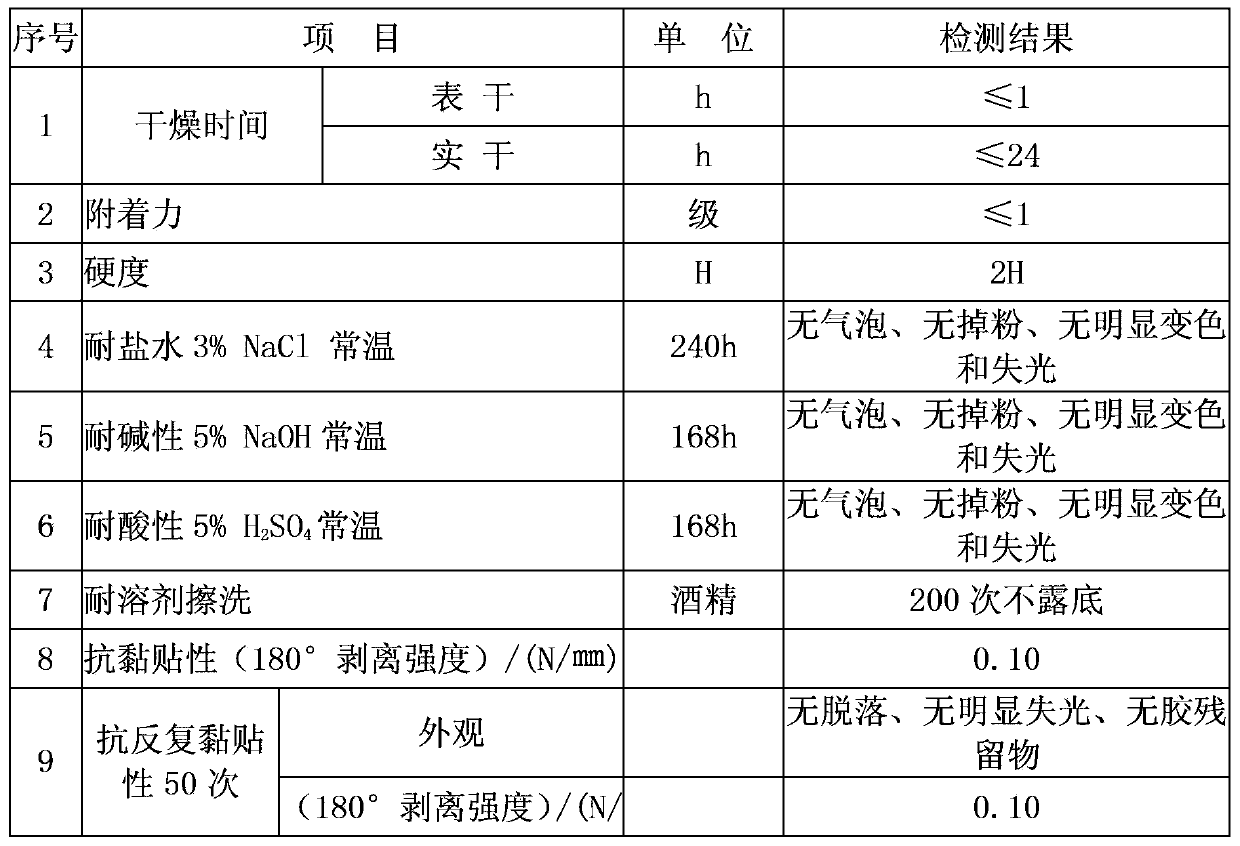

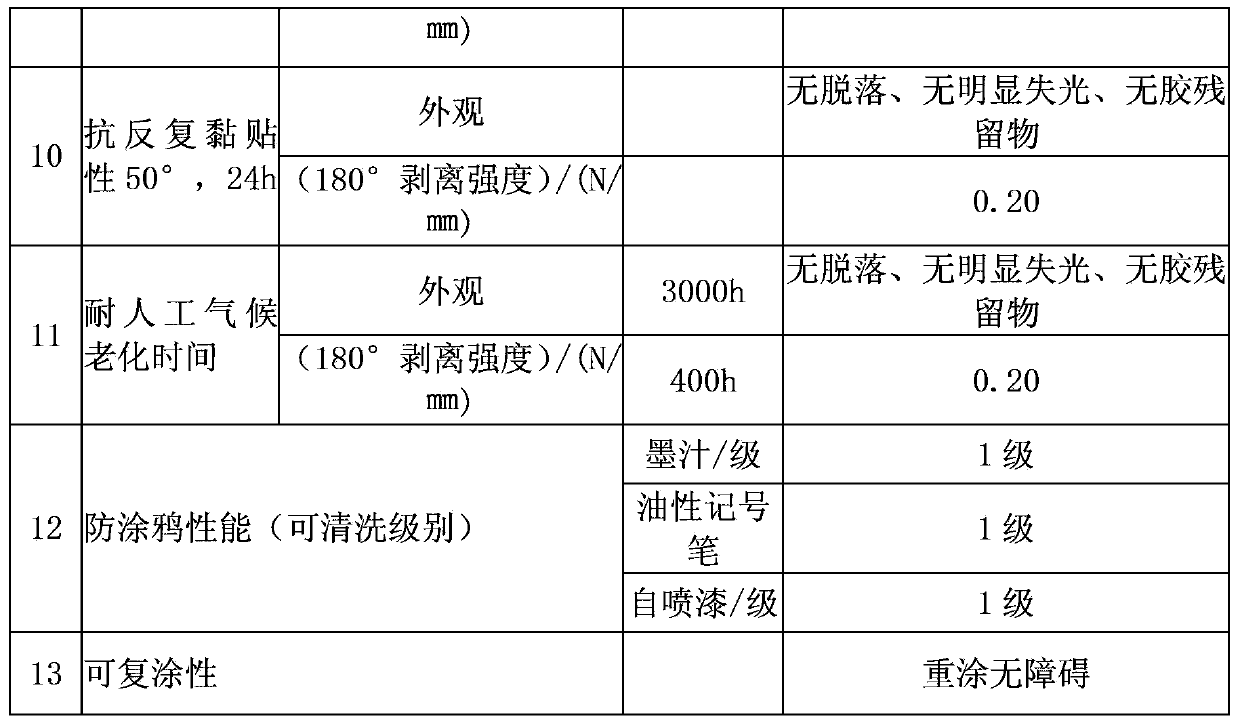

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention are as follows:

[0012] 1. Prefabricate fluorine-modified silicone resin, take 75 parts of sufficient fluorocarbon resin, heat up to 45°C, add 15 parts of polydimethoxysilane dropwise, complete the addition within 60 minutes, keep warm for 45 minutes, add coupling agent dropwise (KH570) 1 part, heat up to 50 degrees for 4 hours and keep stirring, add 0.4 part of reaction accelerator (3M4430). Stir at low speed for 15 minutes, lower the temperature to 45 degrees, keep warm for 2 hours, add 9 parts of butyl acetate after cooling, stir evenly and set aside.

[0013] 2. To prepare the coating, physically mix 65 parts of fluorine-modified silicone resin, 25 parts of rutile titanium dioxide (R902), 7 parts of butyl acetate (reagent grade), and 0.2 parts of dispersant (BYK-110), and then grind and disperse To 20 microns, add 1 part of leveling agent (DE-2050), 0.5 part of non-ionic active agent (3M4432), 0.2 part of defoamer (BYK067), 3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com