Environment-friendly insulating coating liquid as well as preparation method and application thereof

A technology of insulating coating and insulating coating, applied in the direction of coating, anti-corrosion coating, etc., can solve the problems affecting the comprehensive performance of insulating coating, and achieve the effect of excellent lamination coefficient, improved corrosion resistance and good sliding property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

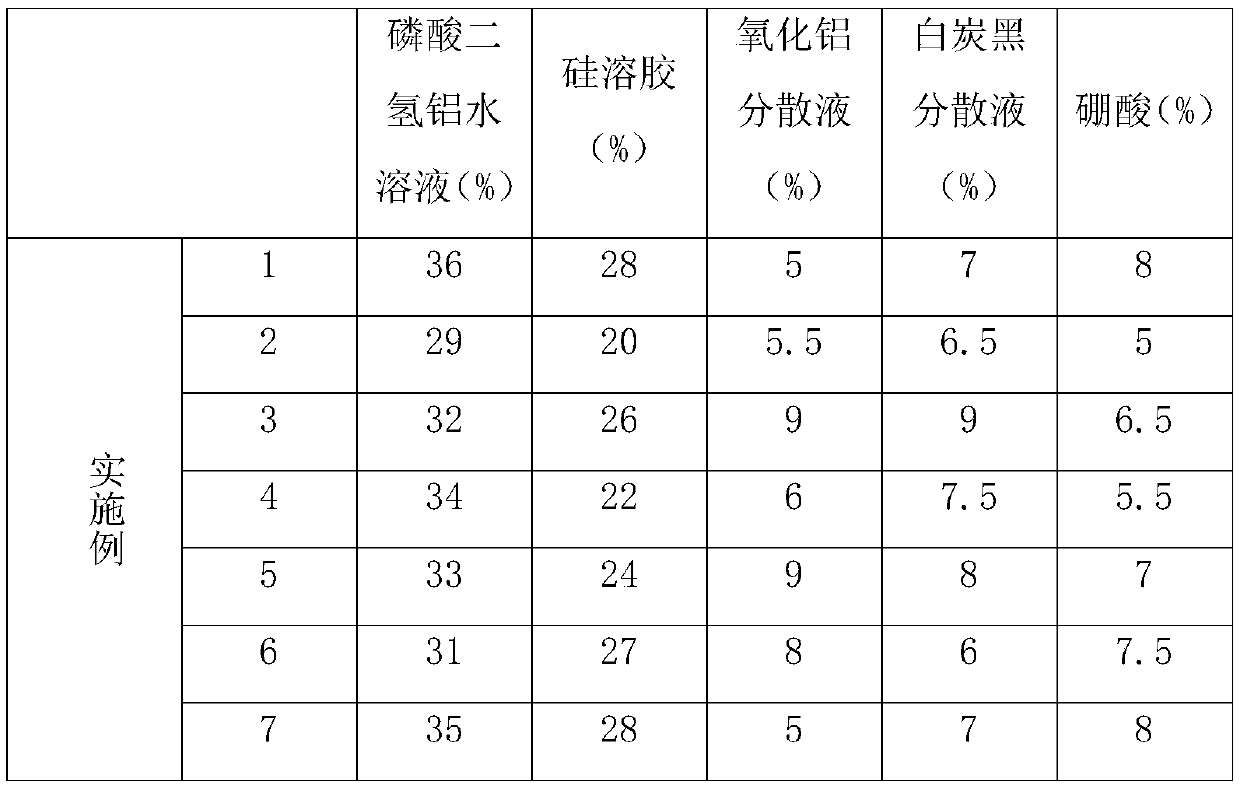

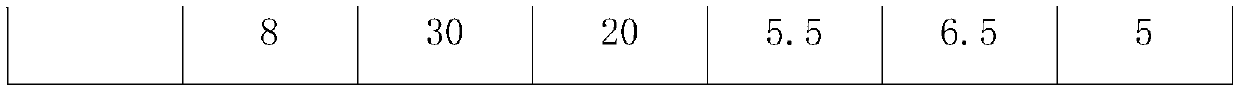

[0054] Compared with Example 1 and Example 7, the addition of aluminum dihydrogen phosphate is too low, the coating is slightly peeled off, and the corrosion resistance is general. Compared with Example 8, the addition amount of aluminum dihydrogen phosphate is too high, and the local lamination coefficient of the coating is reduced. It can be seen from the examples that the addition of aluminum dihydrogen phosphate is between 30% and 35%, and the coating has excellent properties.

[0055] Comparing Comparative Example 1 with Example 7, due to the low silica sol, the coating density is poor, the corrosion resistance is general, and the part is not smooth. Compared with Example 8 in Comparative Example 2, the silica sol is too high, and the corrosion resistance of the coating is average. It can be seen from the examples that the addition of silica sol is between 20% and 28%, and the coating has excellent properties.

[0056] Compared with Example 3, Comparative Example 3 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com