Anti-sticking solid lubricating coating and its preparation method and coating method

A solid lubrication and coating technology, applied in epoxy resin coatings, coatings, and devices for coating liquids on surfaces, can solve problems such as heavy metal powder environmental pollution, meet performance requirements, facilitate industrial implementation, and improve adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

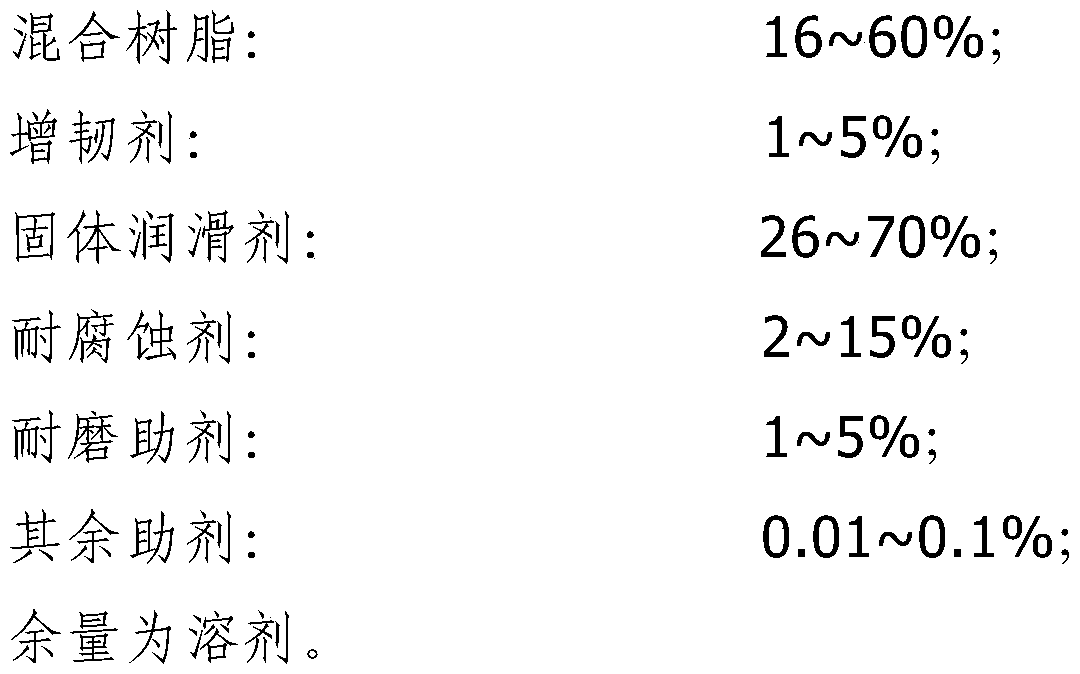

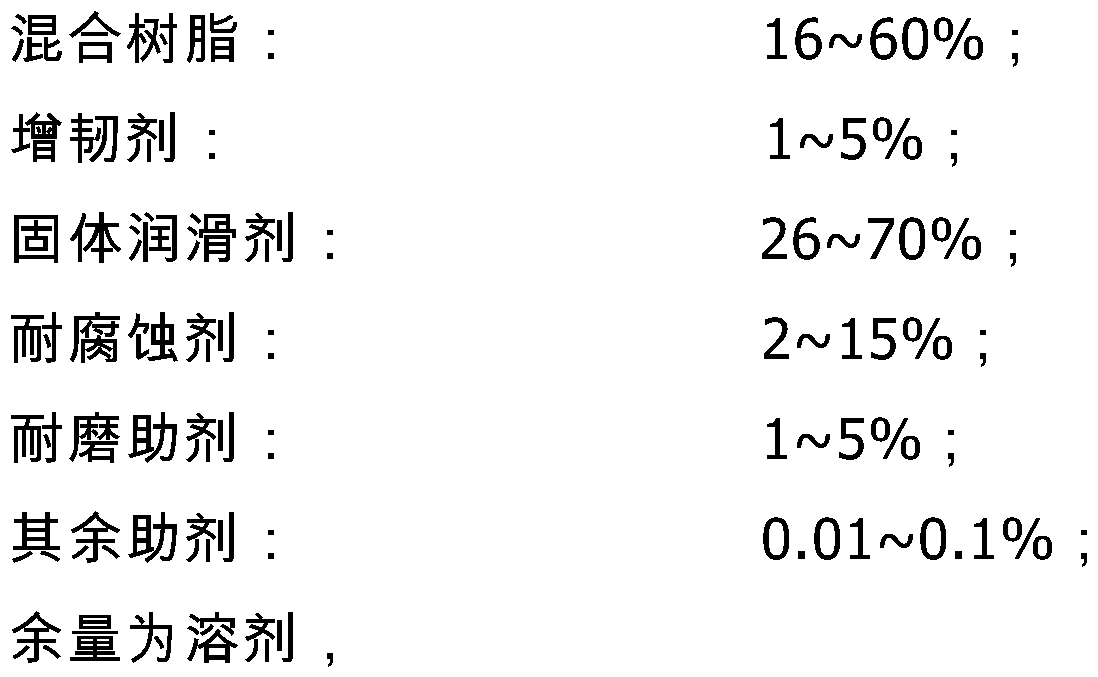

[0029] Coating composition (mass)

[0030] 10% polyamideimide, 19.99% epoxy resin (E51), 1% polyvinyl butyral, 5% tri-n-butyl citrate, 45% molybdenum disulfide (<0.2μm), 1% trioxide Antimony (<0.5μm), 5% polytetrafluoroethylene (<0.2μm), 1% melamine urate, 10% titanium dioxide (<0.12μm), 2% calcium stearate, 0.01% additives.

[0031] Coating process: the pressure of the spray gun is 0.25MPa, and the temperature is kept at 220°C for 0.3 hours in a drying oven.

[0032] Results: After the above treatment, the bonding strength between the coating and the threaded joint of 110 steel grade was grade 1; no sticking occurred after 10 times of make-up and breakout; no corrosion spots after 100 hours of neutral salt spray test.

Embodiment 2

[0034] Coating composition (mass)

[0035] 29.99% polyamideimide, 5% epoxy resin (E51), 8% polyvinyl butyral, 1% tri-n-butyl citrate, 20% molybdenum disulfide (<0.2μm), 10% trioxide Antimony (<0.5μm), 15% polytetrafluoroethylene (<0.2μm), 5% melamine urate, 1% titanium dioxide (<0.12μm), 5% calcium stearate, 0.01% additives.

[0036] Coating process: the pressure of the spray gun is 0.25MPa, and the temperature is kept at 250°C for 0.3 hours in a drying oven.

[0037] Results: After the above treatment, the bonding strength between the coating and the threaded joint of 110 steel grade was grade 1; no sticking occurred after 10 times of make-up and breakout; no corrosion spots after 100 hours of neutral salt spray test.

Embodiment 3

[0039] Coating composition (mass)

[0040] 20% polyamideimide, 15% epoxy resin (E51), 9.99% polyvinyl butyral, 3% tri-n-butyl citrate, 28% molybdenum disulfide (<0.2μm), 5% trioxide Diantimony (<0.5μm), 8% polytetrafluoroethylene (<0.2μm), 2% melamine urate, 7% titanium dioxide (<0.12μm), 2% calcium stearate, 0.01% additives.

[0041] Coating process: the pressure of the spray gun is 0.25MPa, and the temperature is kept at 230°C for 0.3 hours in a drying oven.

[0042] Results: After the above treatment, the bonding strength between the coating and the threaded joint of 110 steel grade was grade 1; no sticking occurred after 10 times of make-up and breakout; no corrosion spots after 100 hours of neutral salt spray test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com