Anti-bonding master batch for optical-grade biaxially-oriented PET (polyethylene terephthalate) films/sheets and production process thereof

A polyethylene terephthalate, biaxial stretching technology, applied in the field of anti-adhesion masterbatch, can solve the problems of affecting the optical properties of the film and the anti-adhesive effect, reducing the number of anti-adhesive particles, irregular particle shapes, etc. Achieve the effect of reducing powder accumulation on the roller and cleaning equipment, improving printing performance, and improving the rate of high-quality products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment one: An anti-adhesive masterbatch for optical-grade biaxially oriented polyethylene terephthalate film / sheet, specially used for ordinary packaging biaxially oriented polyethylene terephthalate film, consisting of the following components and parts by weight :

[0037] Polyethylene terephthalate 90

[0038] Silica 10

[0039] Among them, PET uses film-grade polyester chips; the anti-sticking agent uses gel method silica, and the particle size is controlled at 3-6um.

[0040] Described masterbatch is made according to the following steps:

[0041] S1 pre-drying;

[0042] S2 is produced by a twin-screw extruder, the temperature of each zone of the extruder is 250-290°C, the speed of the main engine is 200r / min-450r / min, the current is 300-400A, 1-3 stages of vacuum exhaust, vacuum degree -0.05mPa-0.1mPa ;

[0043] S3 granulation;

[0044] S4 The finished product is dried.

[0045] The material is cut by high-precision weighing. The screw element of the...

Embodiment 2

[0047] Embodiment two: An anti-adhesive masterbatch for optical-grade biaxially oriented polyethylene terephthalate film / sheet, specially used for ordinary packaging biaxially oriented polyethylene terephthalate film, consisting of the following components and parts by weight :

[0048] Polyethylene terephthalate 77.5

[0049] China clay 20

[0050] Ethylene bis stearic acid amide 2.5

[0051] Among them, polyethylene terephthalate is made of film-grade polyester chips, the anti-sticking agent is made of china clay, and the particle size is controlled at about 5-7um.

Embodiment 3

[0052] Embodiment three: An anti-adhesive masterbatch for optical-grade biaxially oriented polyethylene terephthalate film / sheet, specially used for ordinary packaging biaxially oriented polyethylene terephthalate film, consisting of the following components and parts by weight :

[0053] Polyethylene terephthalate 69.999

[0055] Polyethylene wax 0.001

[0056] Among them, polyethylene terephthalate is made of film-grade polyester chips, anti-sticking agent is made of calcium carbonate, and the particle size is controlled at about 6-8um.

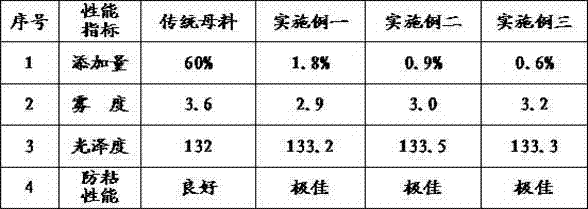

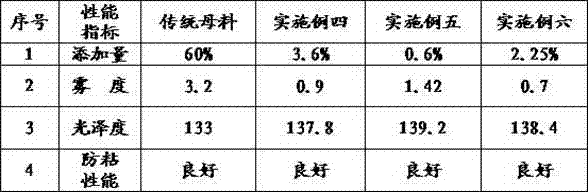

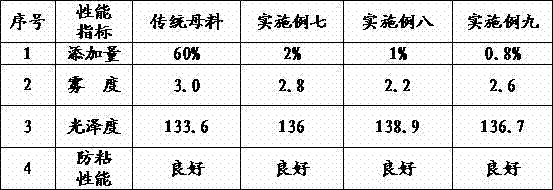

[0057] Comparative test: Based on the production of 12um biaxially oriented polyethylene terephthalate film, three formulations of anti-adhesive masterbatches were added respectively, and the test results were as follows:

[0058]

[0059] The test shows that: the anti-adhesive masterbatch prepared by adopting the method of twin-screw extruder and selecting the inorganic particles with a fixed size and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com