Treatment method capable of improving anti-cracking property of rattan

A technology of anti-cracking performance and treatment method, applied in the direction of wood treatment, low temperature treatment, wood low temperature treatment, etc., can solve the problems of tough texture, poor flexibility, human health hazards, unfavorable processing and production, etc., to achieve sufficient softening, good effect, good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

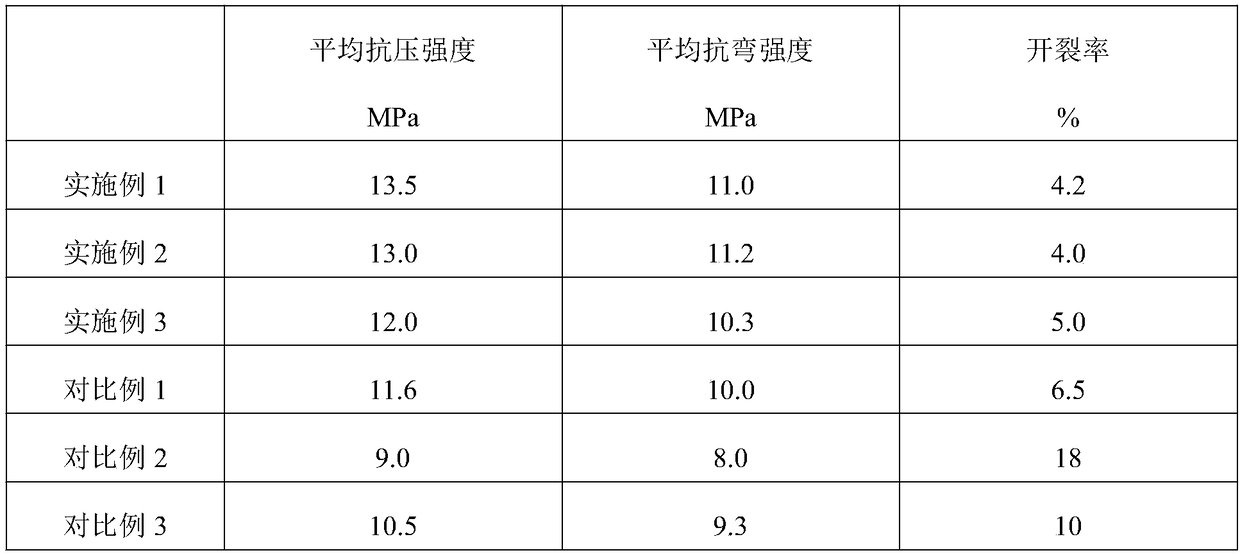

Examples

Embodiment 1

[0025] A treatment method for improving the anti-crack performance of rattan, comprising the following steps:

[0026] S1. Pre-treatment: Select intact rattans without moths, remove the leaves of the rattans, wash with water to remove impurities, then soak them in 0.6% salt solution for 4 hours, take out the rattans and drain the water.

[0027] S2. Freezing treatment: freeze the pretreated rattan in a refrigerator at -20°C for 4 hours, and then dry it at 60°C until the water content is 40% for later use.

[0028] S3. Cooking: put the frozen rattan into the cooking liquid, heat to 95° C. and cook for 15 minutes, take out the rattan, rinse it with clean water and set aside.

[0029] The cooking liquid comprises: 10% citric acid, 2% potassium permanganate, 3% trisodium phosphate, and the rest is water.

[0030] S4. Softening treatment: soak the steamed rattan in a softener, and use ultrasonic waves during the soaking process, and use ultrasonic waves with a frequency of 35 kHz ...

Embodiment 2

[0035] A treatment method for improving the anti-crack performance of rattan, comprising the following steps:

[0036] S1. Pre-treatment: select intact rattans without moths, remove the leaves of the rattans, wash with water to remove impurities, then soak them in 0.5% salt solution for 5 hours, take out the rattans and drain the water.

[0037] S2. Freezing treatment: freeze the pretreated rattan in a refrigerator at -15° C. for 5 hours, and then dry it at 40° C. until the water content is 30% for later use.

[0038] S3. Cooking: put the frozen rattan into the cooking liquid, heat to 90°C and cook for 20 minutes, take out the rattan, rinse it with clean water and set aside.

[0039] The cooking liquid comprises: 15% of citric acid, 1% of potassium permanganate, 1% of trisodium phosphate, and the rest is water.

[0040] S4. Softening treatment: soak the boiled rattan in a softener, and use ultrasonic waves during the soaking process, and use ultrasonic waves with a frequency ...

Embodiment 3

[0045] A treatment method for improving the anti-crack performance of rattan, comprising the following steps:

[0046] S1. Pre-treatment: select intact rattans without moths, remove the leaves of the rattans, wash with water to remove impurities, then soak them in 0.7% salt solution for 3 hours, take out the rattans and drain the water.

[0047] S2. Freezing treatment: freeze the pretreated rattan in a refrigerator at -20° C. for 3 hours, and set aside.

[0048] S3. Cooking: put the frozen rattan into the cooking liquid, heat to 95° C. and cook for 15 minutes, take out the rattan, rinse it with clean water and set aside.

[0049] The cooking liquid comprises: 5% citric acid, 3% potassium permanganate, 5% trisodium phosphate, and the rest is water.

[0050] S4. Softening treatment: soak the steamed rattan in a softener for 10 hours.

[0051] The softener comprises the following components in parts by weight: 20 parts of aloe vera gel, 3 parts of chitosan quaternary ammonium sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com