Preparation method and formula of soap-free synthetic water-based acrylic dispersion resin

A water-based acrylic and dispersion technology, applied in the direction of coating, etc., can solve the problems of anti-adhesion, system instability, hardness, poor initial anti-adhesion grinding performance and flexibility, etc., and achieve excellent permeability and adhesion Focus on excellent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

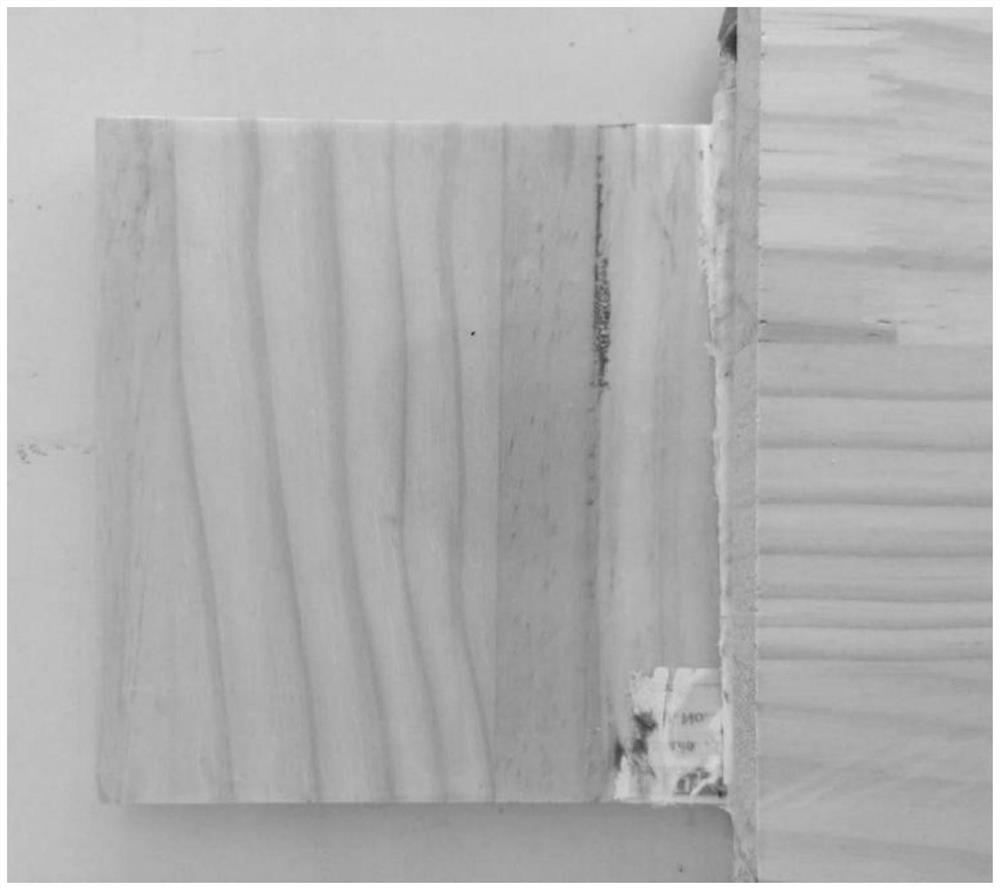

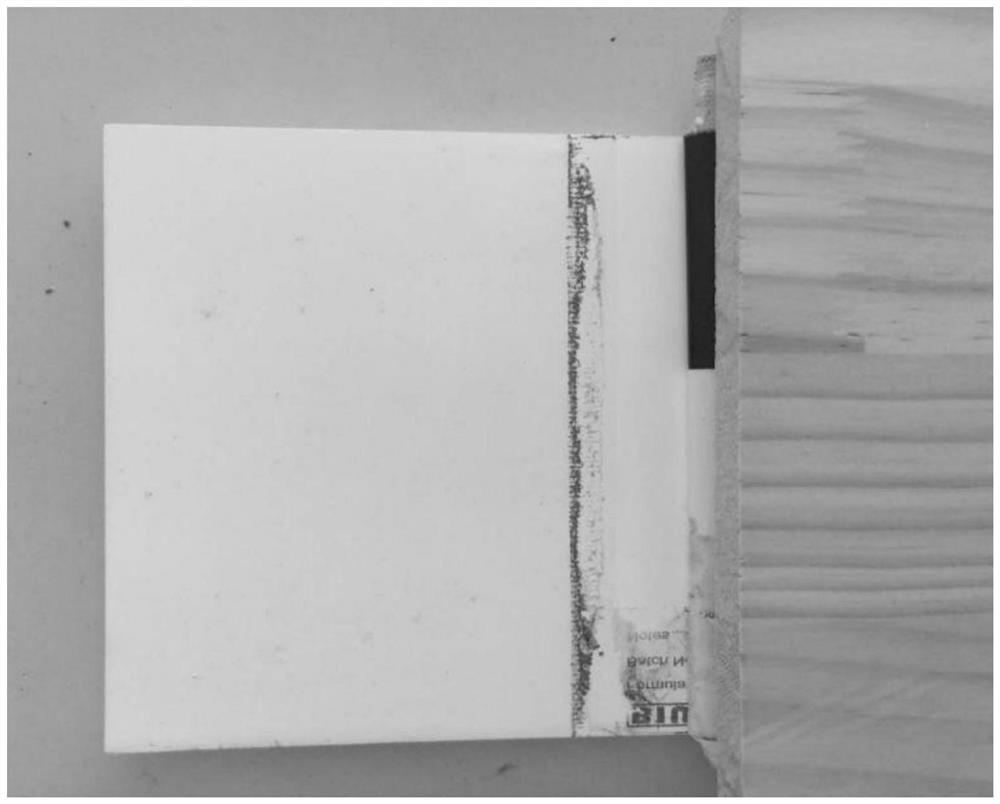

Image

Examples

Embodiment

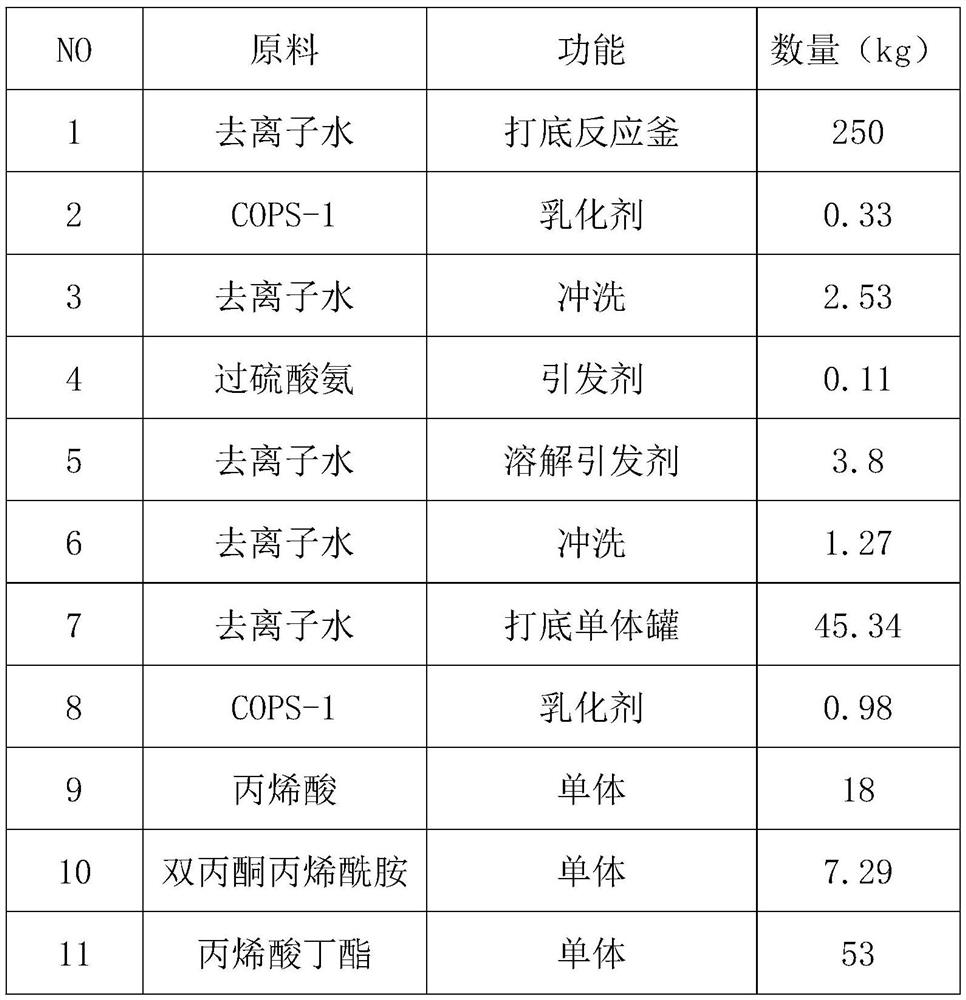

[0037] A kind of preparation method of soap-free synthetic waterborne acrylic acid dispersion resin, comprises the following steps:

[0038] S1. Add 250kg of deionized water to the reactor, stir at a speed of 25 rpm, add 0.33kg of emulsifier COPS-1, and rinse the emulsifier COPS-1 remaining in the container with 2.53kg of deionized water into the reactor, and then the reactor was heated to 75°C;

[0039] S2, the ammonium sulfate of crossing 0.11kg and the deionized water of 3.8kg are added initiator shot tank, the ammonium sulfate remaining in the container is rinsed in the reactor with the deionized water of 1.27kg, make initial initiator for subsequent use;

[0040] S3. Add 45.34kg of deionized water into the monomer tank, stir at a speed of 50 rpm, add 0.98kg of emulsifier COPS-1 to blend and disperse evenly;

[0041] S4, the acrylic acid of 18kg, the diacetone acrylamide of 7.29kg, the butyl acrylate of 53kg, the dimethyl ester of 78kg and the lauryl mercaptan of 2.92kg a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com