Wall body masonry method

A wall and masonry technology, applied in the direction of walls, buildings, building components, etc., to achieve the effect of improving anti-penetration performance, speeding up construction progress, excellent heat insulation and anti-penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

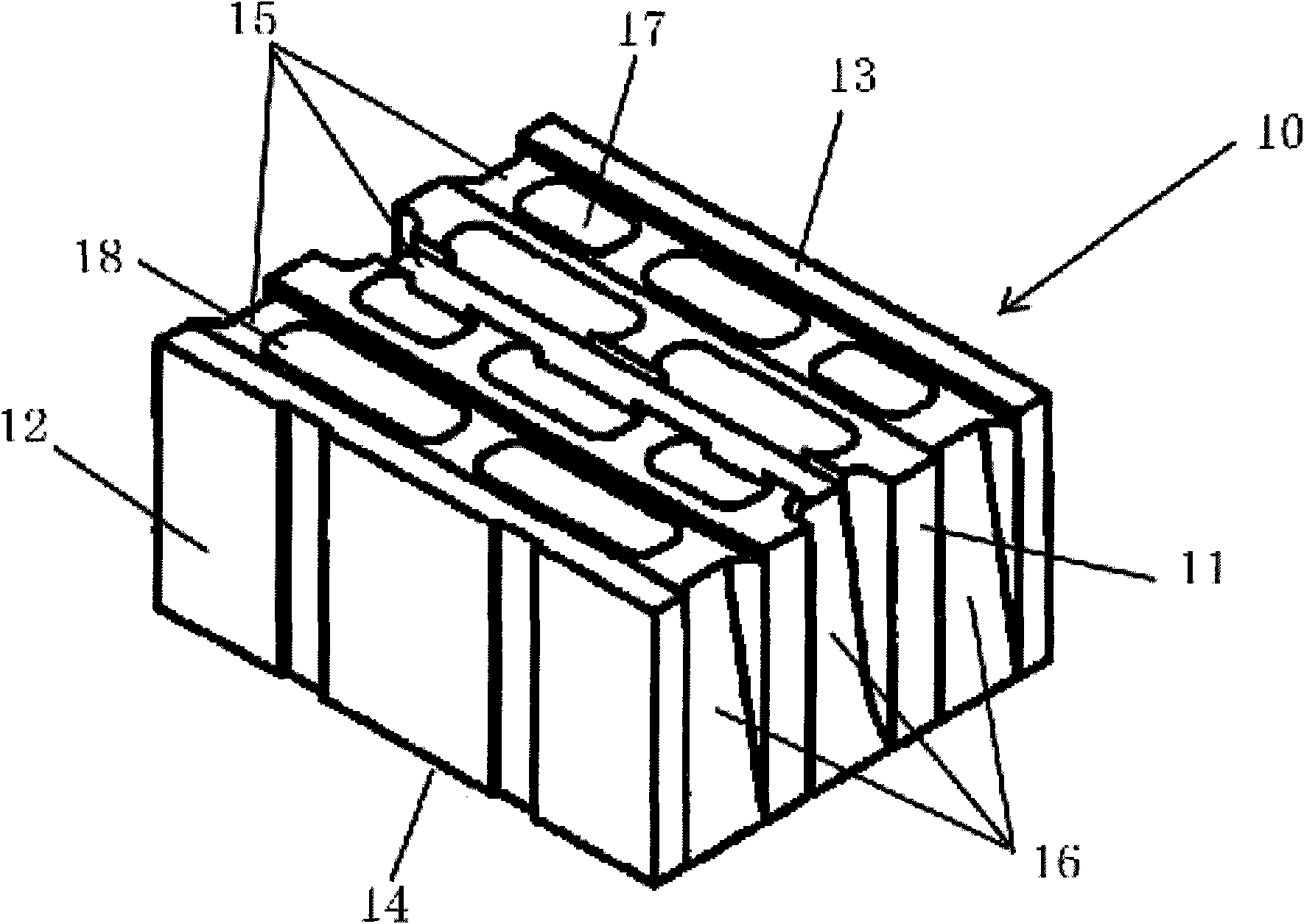

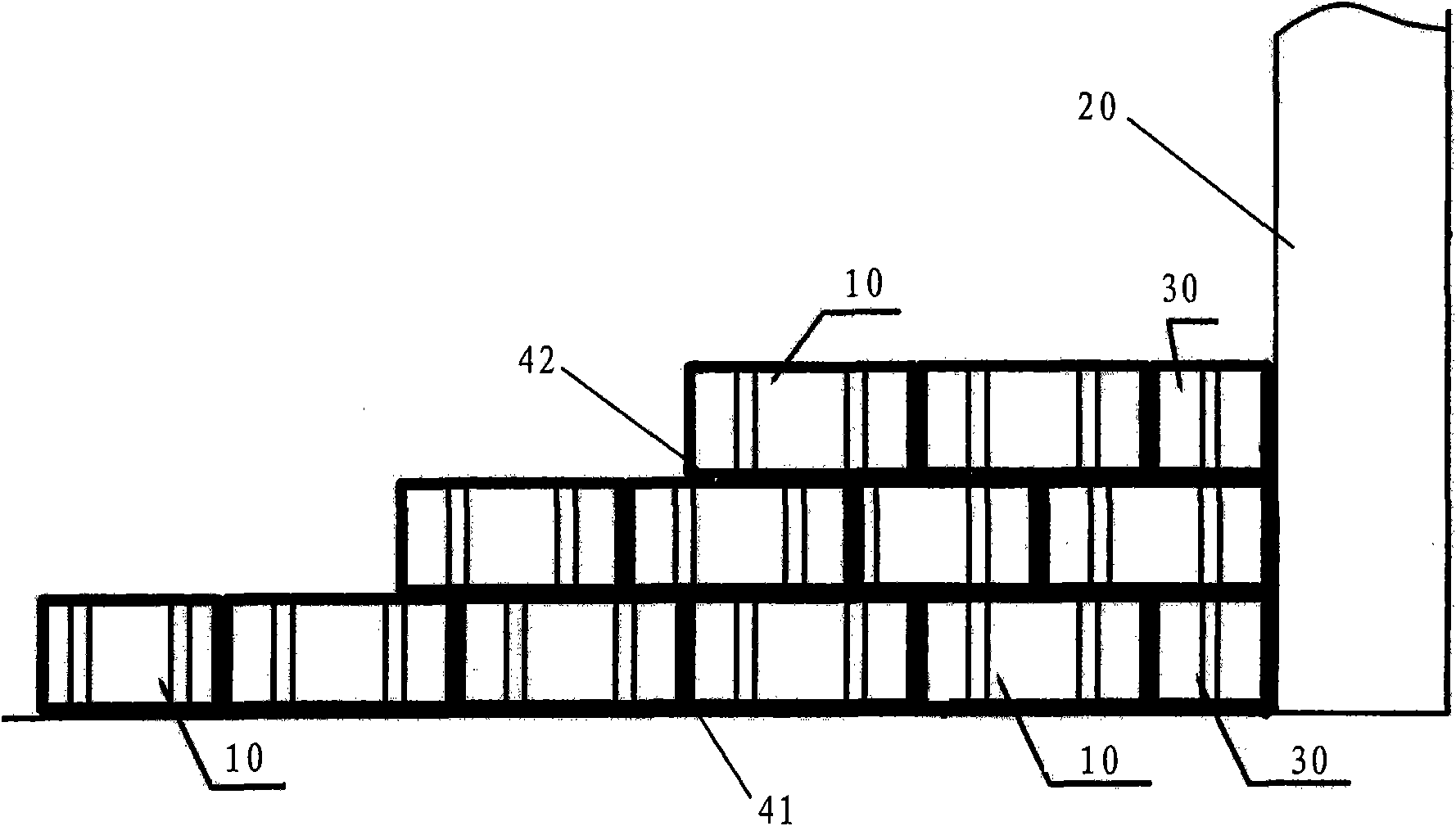

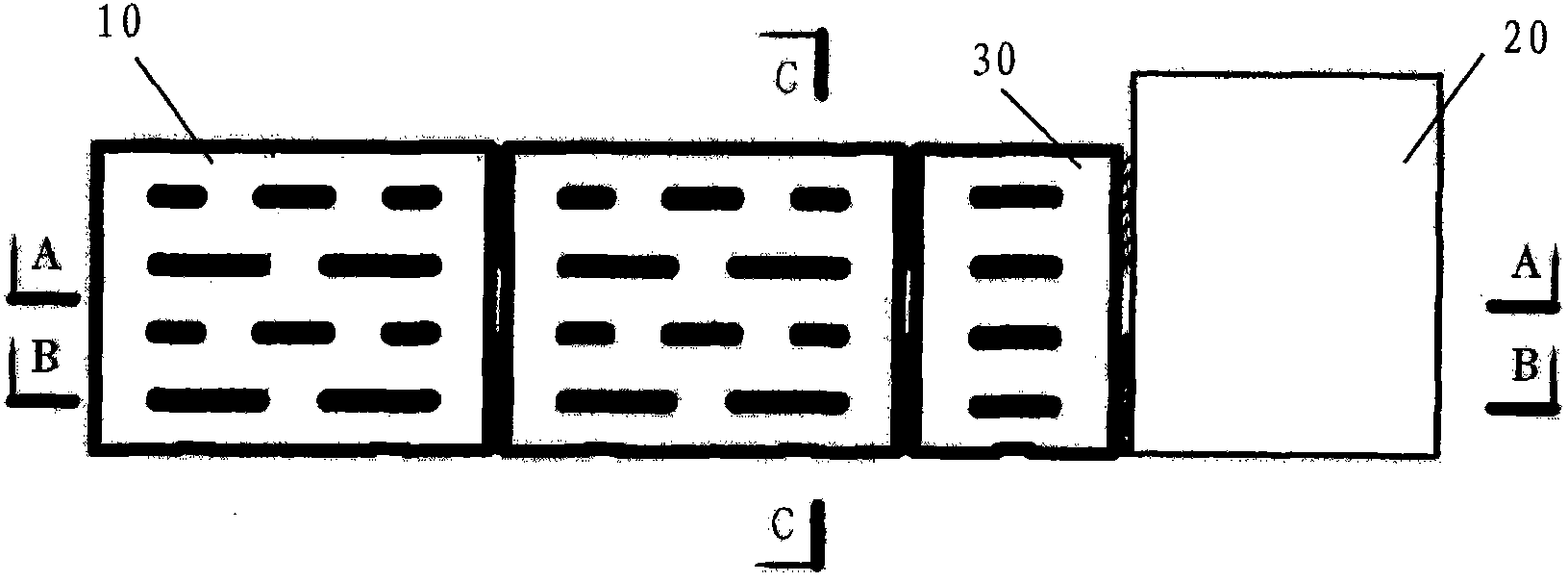

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this description, the principle of the present invention will be described through embodiments. Other aspects, features and advantages of the present invention will become clear at a glance through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

[0033] A wall masonry method provided by the embodiment of the present invention is suitable for using concrete hollow bricks as the basic structural unit to pile up the wall. The method includes horizontal masonry and vertical masonry, and the horizontal masonry and vertical masonry are Implement sequentially or alternately.

[0034] Among them, horizontal masonry is to build concrete hollow bricks one by one on the same horizontal line, adjacent

[0035] The end faces of the concrete hollow bricks are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com