Composite type wood softening agent

A softener and composite technology, applied in the field of wood anatomy, can solve the problems of unsatisfactory softening effect, obstacles to the promotion and application of wood softeners, and low equipment requirements, so as to improve the softening effect, good plasticity, and improve plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

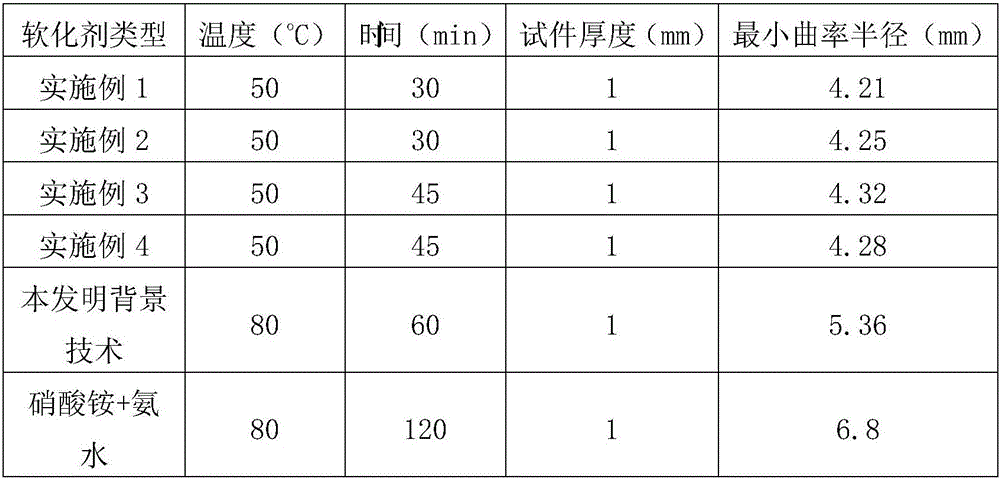

Examples

Embodiment 1

[0019] In this implementation, the mesh number of talcum powder is 1000 mesh; The mesh number of organic bentonite is 400 mesh;

[0020] A composite wood softener, which is made of the following components by weight: 4 parts of talcum powder, 4 parts of organic bentonite, 15 parts of polyoxyethylene fatty acid ester, 3 parts of dodecyl dimethyl betaine 3 parts of sodium lauryl sulfate, 3 parts of zinc stearate, 2 parts of calcium stearate, 2 parts of sodium stearate, 65 parts of chlorinated paraffin, 5 parts of fatty alcohol polyoxyethylene ether, polyglycerol fat 5 parts of acid ester, 2 parts of polydimethylsiloxane, 1.5 parts of disodium edetate, 1.5 parts of triethanolamine, and 140 parts of deionized water.

Embodiment 2

[0022] In this implementation, the mesh number of talcum powder is 800 mesh; The mesh number of organic bentonite is 200 mesh;

[0023] A composite wood softener, made of the following components in proportion by weight: 2 parts of talcum powder, 2 parts of organic bentonite, 10 parts of polyoxyethylene fatty acid ester, 2 parts of lauryl dimethyl betaine 1 part of sodium lauryl sulfate, 2 parts of zinc stearate, 1 part of calcium stearate, 1 part of sodium stearate, 60 parts of chlorinated paraffin, 2 parts of fatty alcohol polyoxyethylene ether, polyglycerol fat 3 parts of acid ester, 1 part of polydimethylsiloxane, 1 part of disodium edetate, 1 part of triethanolamine, 120 parts of deionized water.

Embodiment 3

[0025] In this implementation, the mesh number of talcum powder is 1000 mesh; The mesh number of organic bentonite is 400 mesh;

[0026] A composite wood softener, made of the following components in proportion by weight: 5 parts of talcum powder, 6 parts of organic bentonite, 20 parts of polyoxyethylene fatty acid ester, 5 parts of lauryl dimethyl betaine 4 parts of sodium lauryl sulfate, 4 parts of zinc stearate, 3 parts of calcium stearate, 3 parts of sodium stearate, 70 parts of chlorinated paraffin, 8 parts of fatty alcohol polyoxyethylene ether, polyglycerol fat 7 parts of acid ester, 3 parts of polydimethylsiloxane, 2 parts of disodium edetate, 2 parts of triethanolamine, 150 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com