Preparation method of current collection sliding material and application of product prepared from material

A technology of sliding material and manufacturing method, applied in the field of metal materials, can solve the problems of rising price of pantograph, complicated process and management, etc., and achieve the effect of simple process, excellent electrical conductivity and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

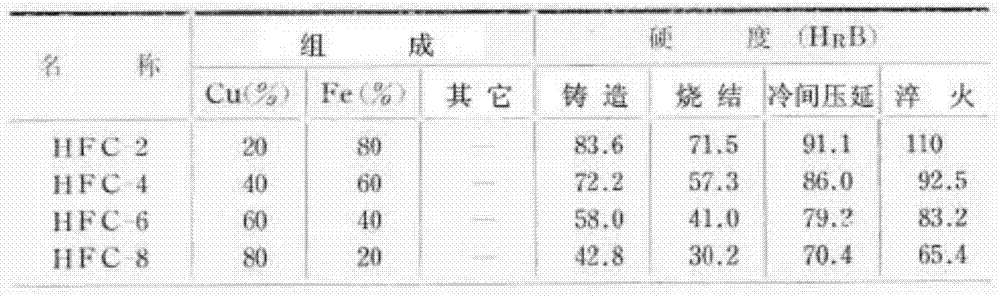

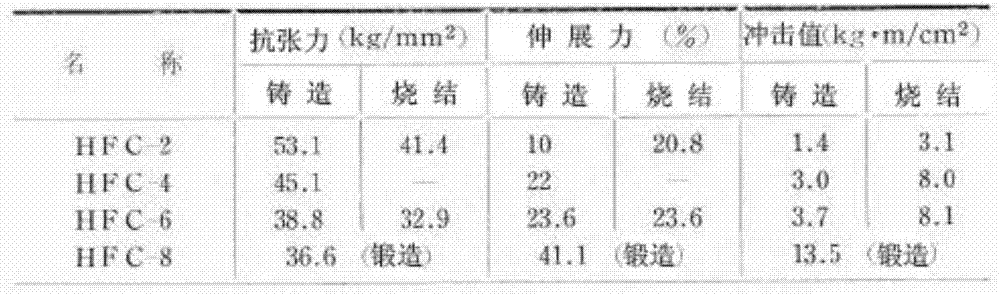

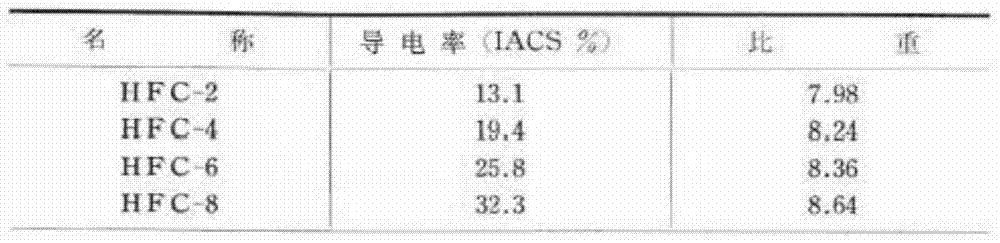

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention are introduced below.

[0020] First, the preparation method of the current-collecting sliding material is introduced:

[0021] Step 1. Dissolve high-quality copper in an electric furnace. Generally, copper with a purity greater than 99.9% is called high-quality copper. Put the broken copper pieces into the electrical furnace for stirring, raise the temperature above the melting point of copper (810.24k), and deoxidize after melting.

[0022] (1) For dehydrogenation, adjust the partial pressure of oxygen to a high level, the range of partial pressure of oxygen: 1.5atm~3atm. At the same time, keep the temperature adjusted to 50°C to 100°C above the melting point of copper, so that the oxygen element on the molten copper will increase, and the hydrogen will be separated regularly, so as to carry out the dehydrogenation process. The phase law here refers to the phase (balance) law, which is phase rule in English. Specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com