Conductive elastic non-woven material and preparation method thereof

A technology of non-woven materials and conductive coatings, which is applied in the manufacture of non-woven fabrics, conductive/antistatic filaments, textiles and paper, and can solve the problems of thick heating fabrics, poor wearing comfort, and fast production speed, and achieve excellent performance Flexible, non-irritating liquid retention rate, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Preparation process of microfiber aggregates such as Figure 4 As shown, the polyolefin elastomer section and carbon nanotubes are mixed and added to the feed funnel 4-1, the polyolefin elastomer section is preheated and melted by the screw extruder 4-2 to form a polymer solution 4-3 into the spinning box 4-4, and the microfiber 4-5 is formed after stretching by the spinter head, and the microfiber 4-5 is deposited on the net curtain 4-7 by using the vacuum suction system 4-6 to obtain a microfiber aggregate;

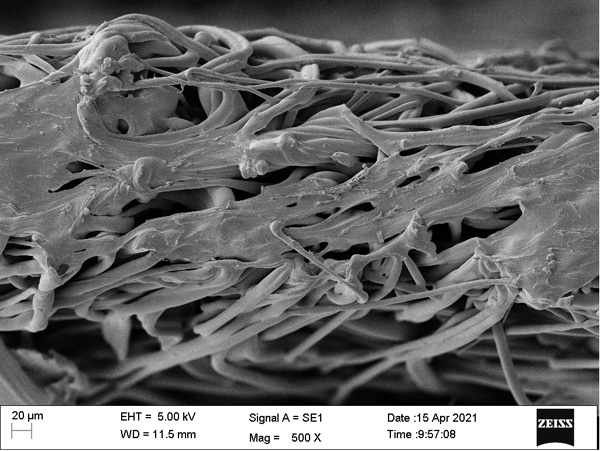

[0056] Microfiber aggregates and conductive coating composite processes such as Figure 5 As shown, the microfiber aggregate 5-1 is placed in a container 5-2 filled with a conductive solution, when the mixed solution composed of graphene dispersion 5-3, aqueous polyurethane 5-4, water 5-5 and wetting agent 5-6 is completely immersed in the pores of the microfiber aggregate 5-1, the pressure roller 5-8 is used for pressure, the excess solution on the surface of the mate...

Embodiment 1

[0058] The preparation method of conductive elastic nonwoven material, the steps are as follows:

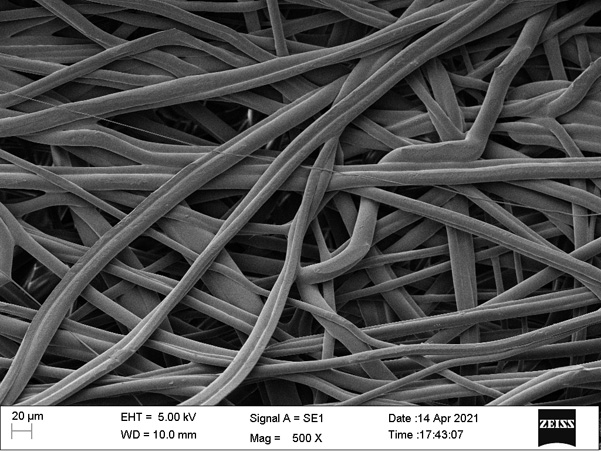

[0059] Preparation of microfiber aggregates: Polyolefin elastomer slices and carbon nanotubes are mixed uniformly by weight ratio of 7:3 and then formed by melt spinning process with a diameter of 10-14um, porosity of 70%-80%, and a isal density of 75-85g / m 2 A collection of microfibers. The polyolefin elastomer model is 7050FL, the ethylene composition is about 13%, the melt index (190 ° C / 2.16 kg) is 10-30g / 10min, the melt flow rate (230 ° C / 2.16kg) is 30-50g / 10min; the multi-walled carbon nanotube resistivity is 0.2-0.3Ω · cm. Set the specific meltblown process parameters as follows: metering pump temperature 200 °C, meltblown die temperature 250 °C, screw extruder temperature (zone 1 - zone 4): 200 °C, 230 °C, 250 °C, 250 °C; metering pump speed of 5Hz, receiving distance of 15cm;

[0060]Preparation of conductive coatings: Graphene dispersion, waterborne polyurethane, w...

Embodiment 2

[0064] The preparation method of the conductive elastic nonwoven material, the difference from Example 1 is that the weight ratio of the polyolefin elastomer slice and carbon nanotubes in the preparation of the microfiber aggregate is 5:5, and the ish density of the conductive elastic nonwoven material is 80g / m 2 。

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com