Copper film containing tungsten nitride for improving thermal stability, electrical conductivity and electric leakage properties and a manufacturing method for the copper film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

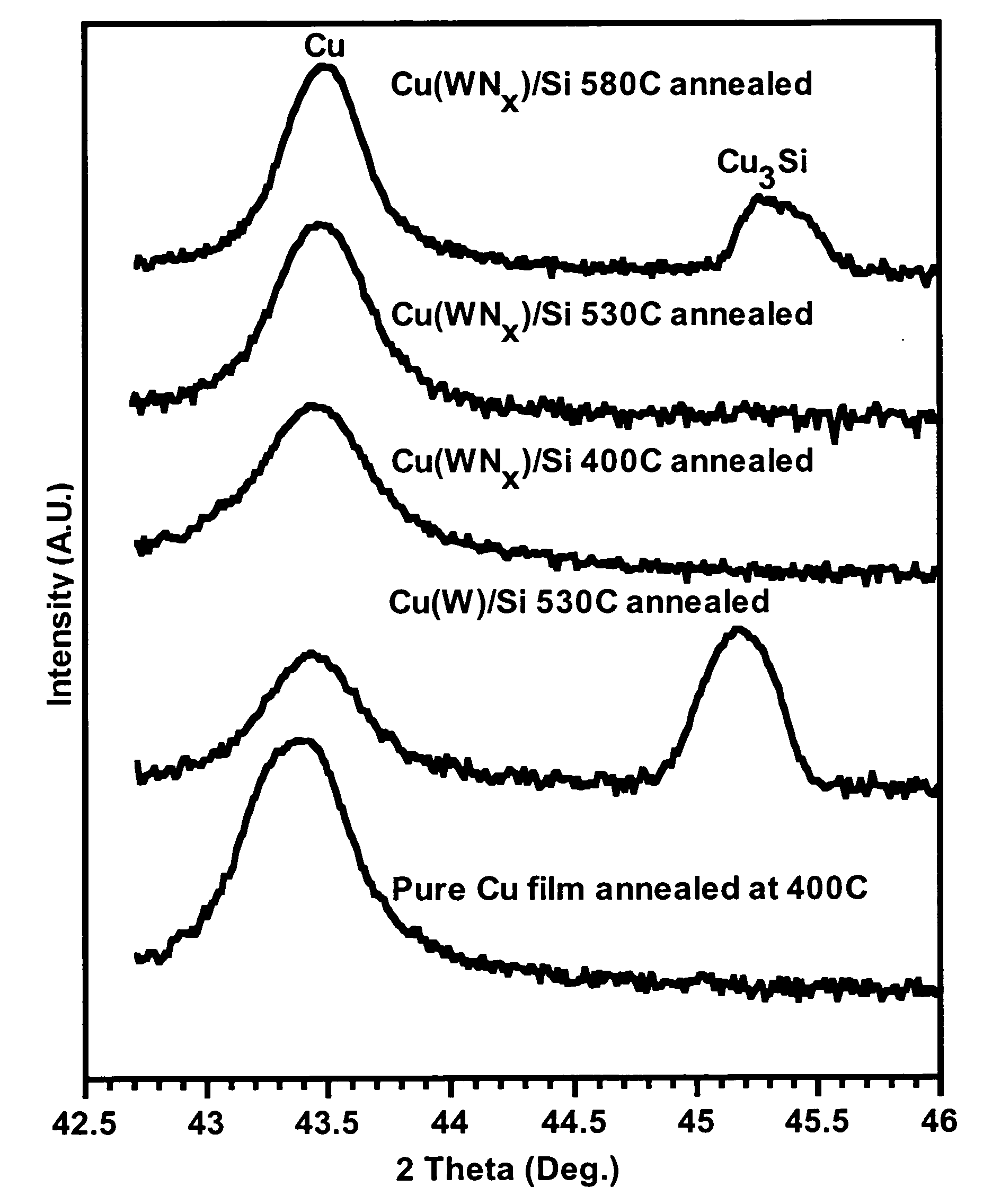

[0038] A copper film containing tungsten nitride in accordance with the present invention is adapted to be formed on a silicon substrate and comprises a copper layer in form of a supersaturated solid solution and tungsten nitride present inside the copper layer that is in structure of nano-crystallite. Composition of a copper film containing the tungsten nitride has atomic ratios of more than 97.5% in copper, 0.5 to 1.5% in tungsten, and less than 2.0% in nitrogen. All atomic ratios above are on a basis of total atoms in the copper film.

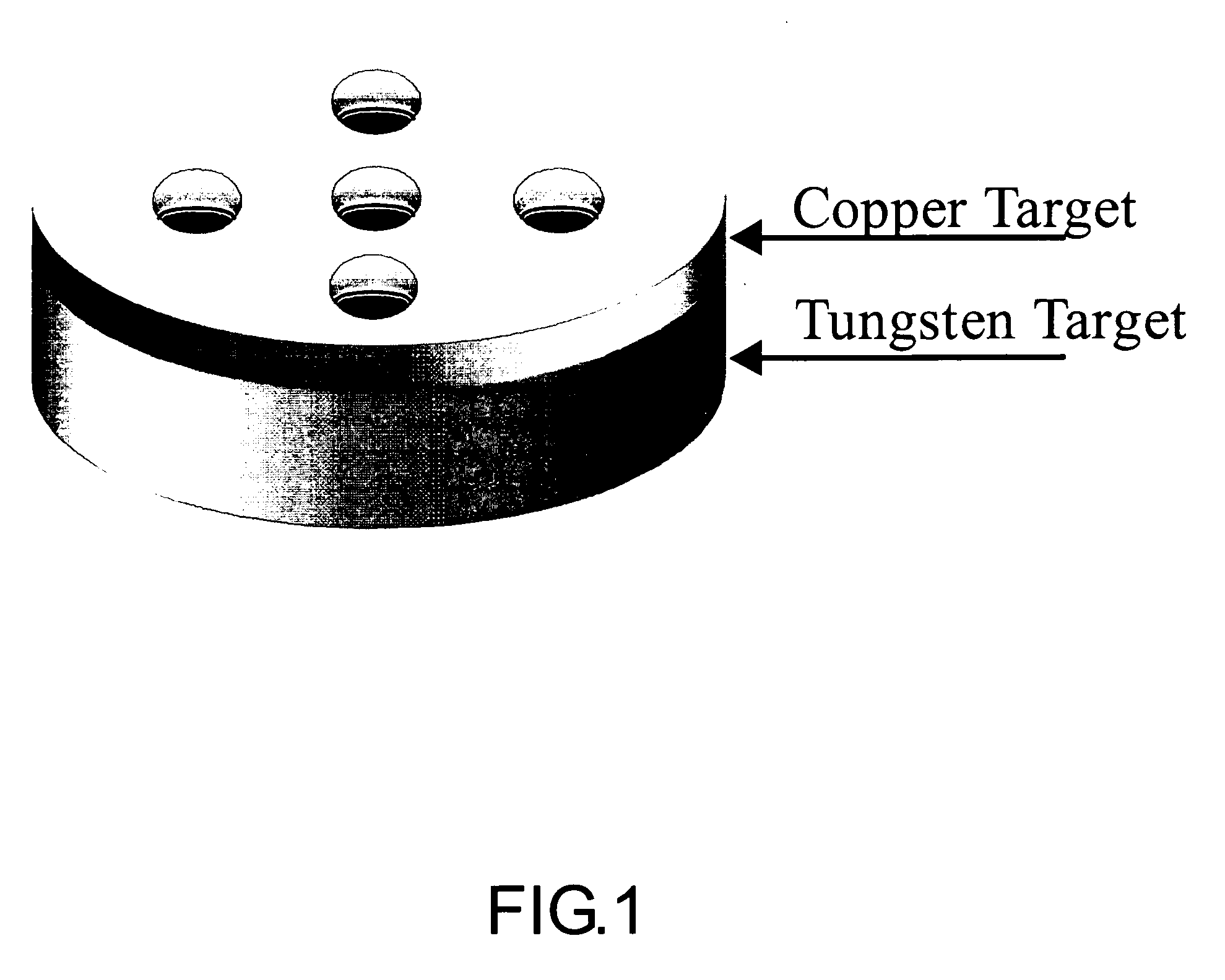

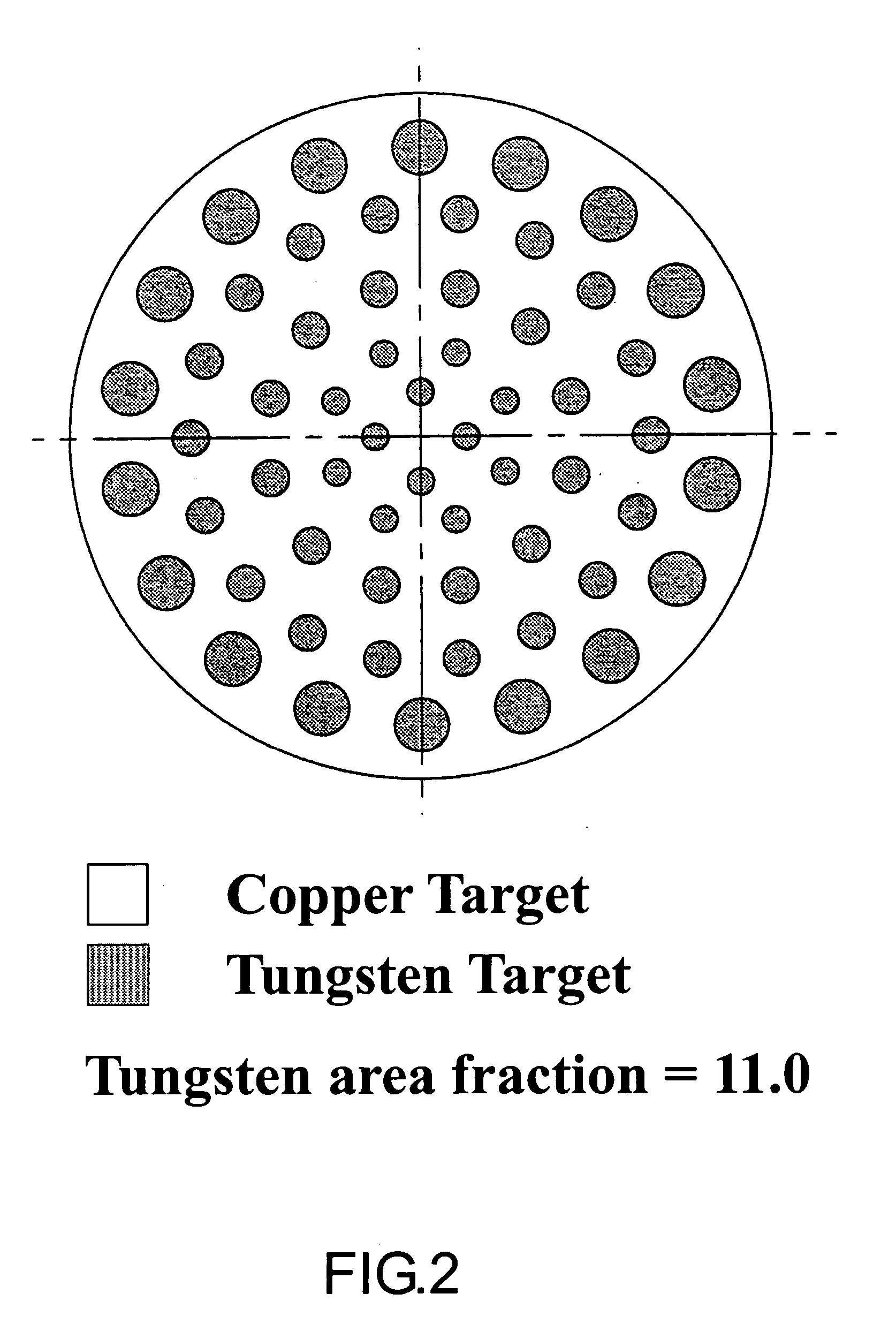

[0039] A method for manufacturing the copper film containing tungsten nitride on the silicon substrate in the present invention comprises acts of: [0040] preparing a vacuum sputtering system having a pressure within 1×102−1×10−3 torr and 1.4-3.7 W / m2W sputtering power; [0041] introducing argon and nitrogen into the vacuum sputtering system to create an Ar / N2 atmosphere; [0042] optionally, adjusting a non-overlapping area between a copper target and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com