Crosslinkable polyethylene insulation material for high-voltage direct-current cable

A cross-linked polyethylene, high-voltage DC technology, used in insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of space charge accumulation and poor electrical conductivity, and achieve excellent electrical conductivity and suppress space charge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment 1: A kind of cross-linkable polyethylene insulating material for high-voltage DC cables in this embodiment consists of 100 parts by weight of low-density polyethylene, 1.5-2.2 parts of cross-linking agent, 0.2-0.5 parts of anti-corrosion It is made of oxygen agent and 0.5-1.2 parts of nano-carbon material.

[0015] This embodiment includes the following beneficial effects:

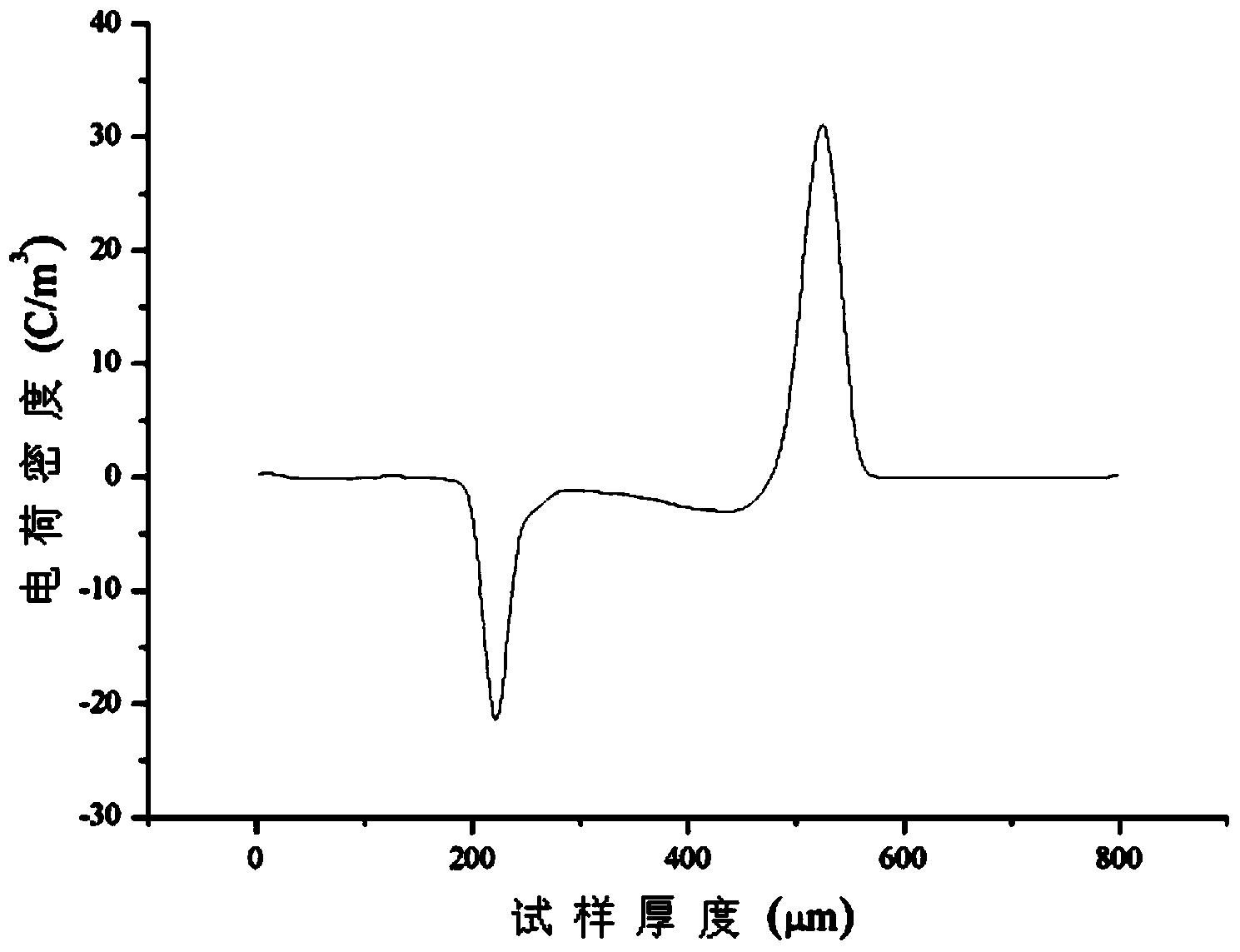

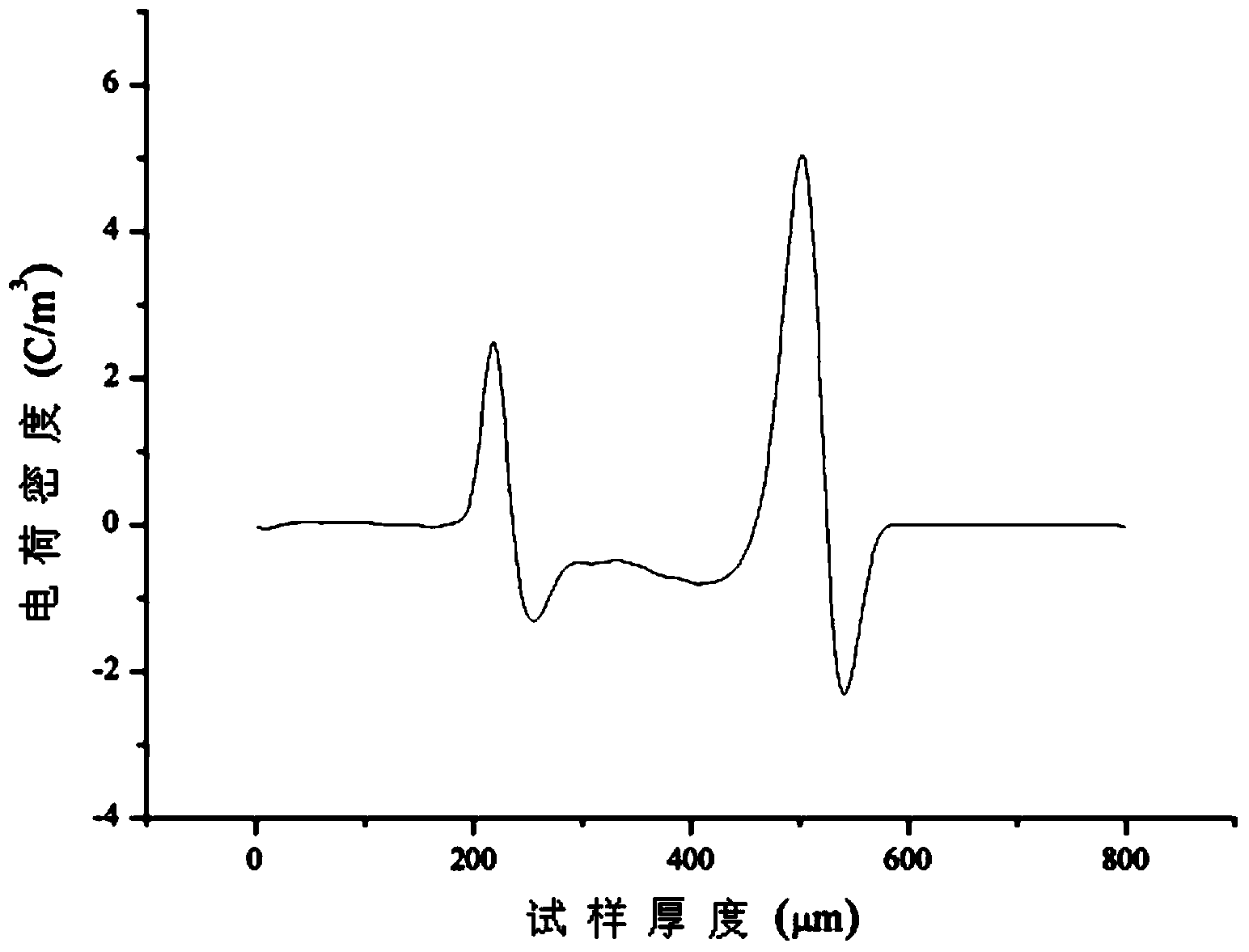

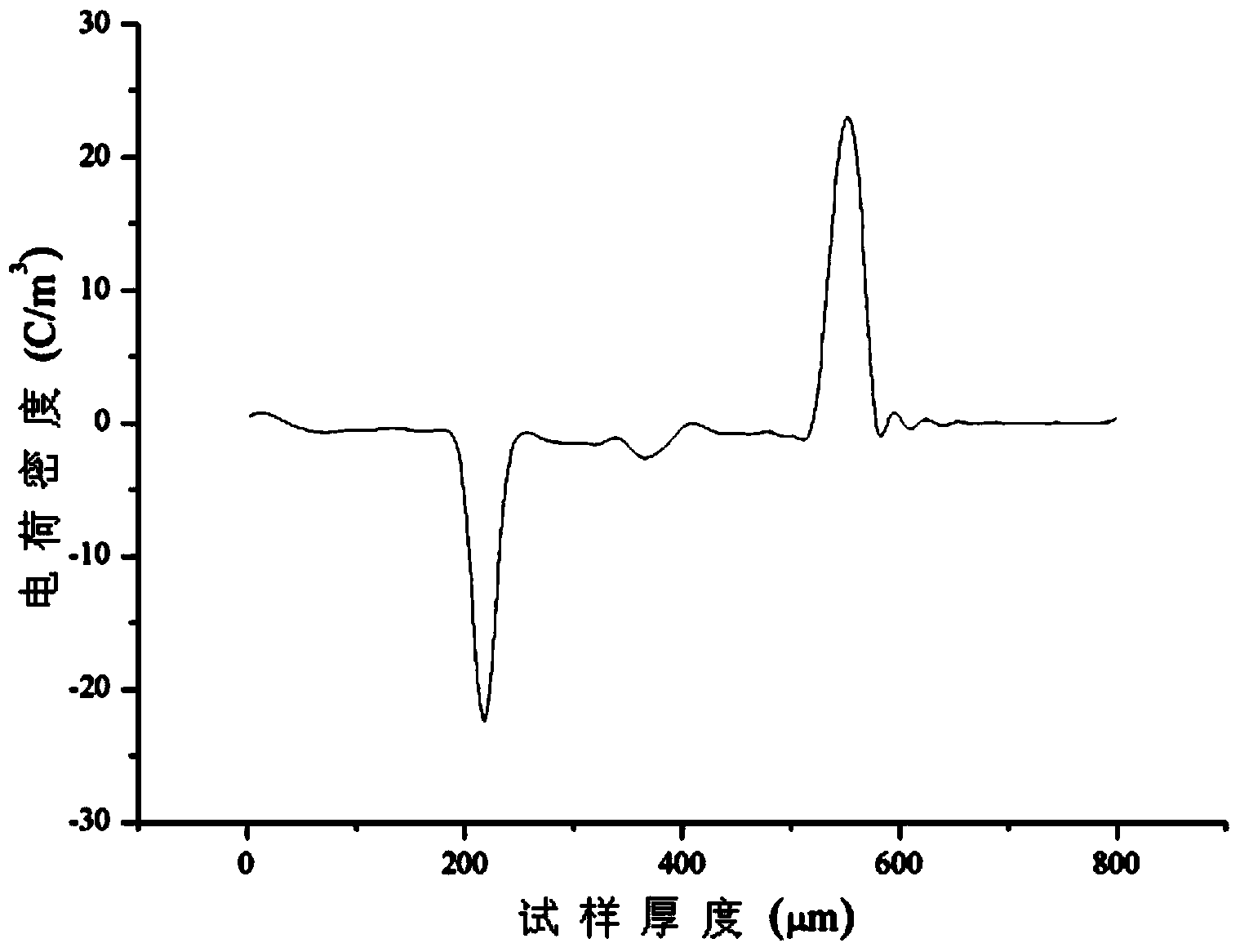

[0016] The electrical conductivity of XLPE filled with nano-carbon materials prepared by using the cross-linkable polyethylene insulating material of this embodiment does not change with the electric field intensity in an electric field below 20kV / mm, and changes by about 1 order of magnitude with temperature, and has excellent electrical conductivity; The cross-linked polyethylene produced by the cross-linkable polyethylene insulating material of the embodiment also has the ability to suppress space charges; the cross-linked polyethylene material prepared by using the cross-link...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the cross-linkable polyethylene insulating material for high-voltage DC cables consists of 100 parts of low-density polyethylene and 1.5 parts of cross-linking agent in parts by weight. , 0.2 parts of antioxidant and 0.5 parts of nano-carbon materials. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment three: The difference between this embodiment and specific embodiment one or two is that the cross-linkable polyethylene insulating material for high-voltage DC cables consists of 100 parts by weight of low-density polyethylene and 1.8 parts of cross-linked polyethylene. Joint agent, 0.3 part of antioxidant and 0.6 part of nano-carbon material. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com