Composite carbon brush for massage chair motor and preparation method thereof

A massage chair and composite technology, which is applied in the field of composite carbon brushes for massage chair motors and its preparation, can solve the problems of failure to meet the needs of massage chair customers, general conductive commutation performance of carbon brushes, poor wear resistance, etc., and achieve suppression The effect of electric spark generation, excellent electrical conductivity, and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

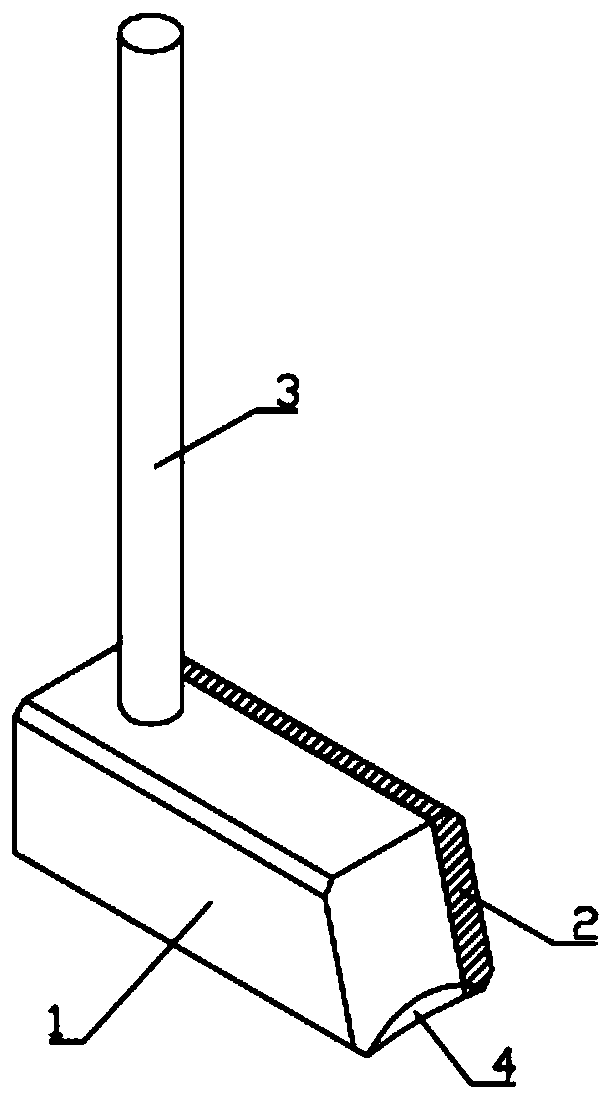

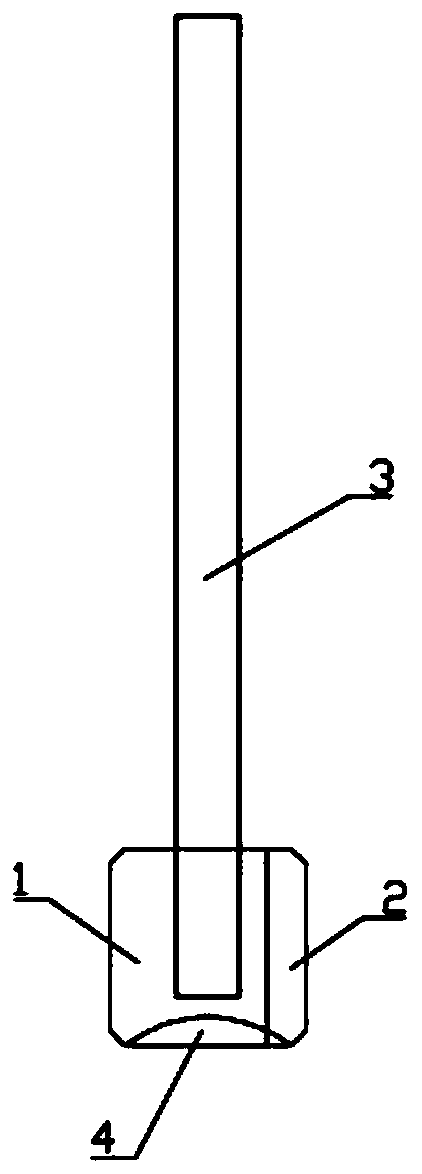

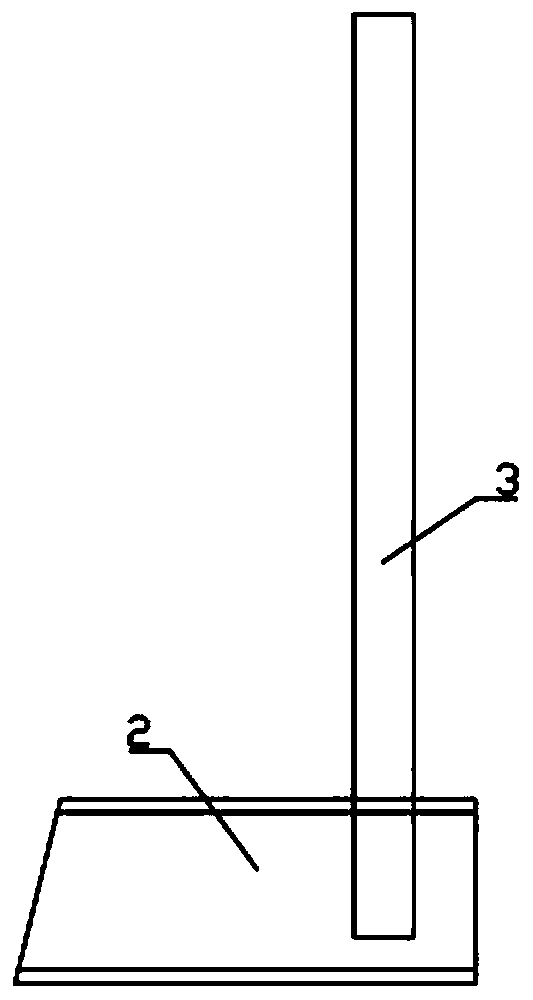

[0022] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] Such as Figure 1-Figure 5 As shown, the composite carbon brush for a massage chair motor of the present invention includes an upper low-resistance high-conductivity layer 1 and a lower high-resistance ultra-high lubricating layer 2, and also includes a carbon brush wire 3, and one end of the carbon brush wire 3 is inserted vertically Located in the low-resistance and high-conductivity layer 1 , the front ends of the low-resistance and high-conductivity layer 1 and the high-resistance ultra-high lubricating layer 2 are provided with a crescent-shaped circular arc gap 4 .

[0024] As a preferred solution, the carbon brush wire 3 is inserted at the rear end of the right side of the low-resistance high-conductivity layer 1, and the cresc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com