High-thermal-conductivity conductive adhesive and preparation method thereof

A technology of conductive adhesive and high thermal conductivity, which is applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problem of short service life of electronic components, and achieve the effect of improving performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

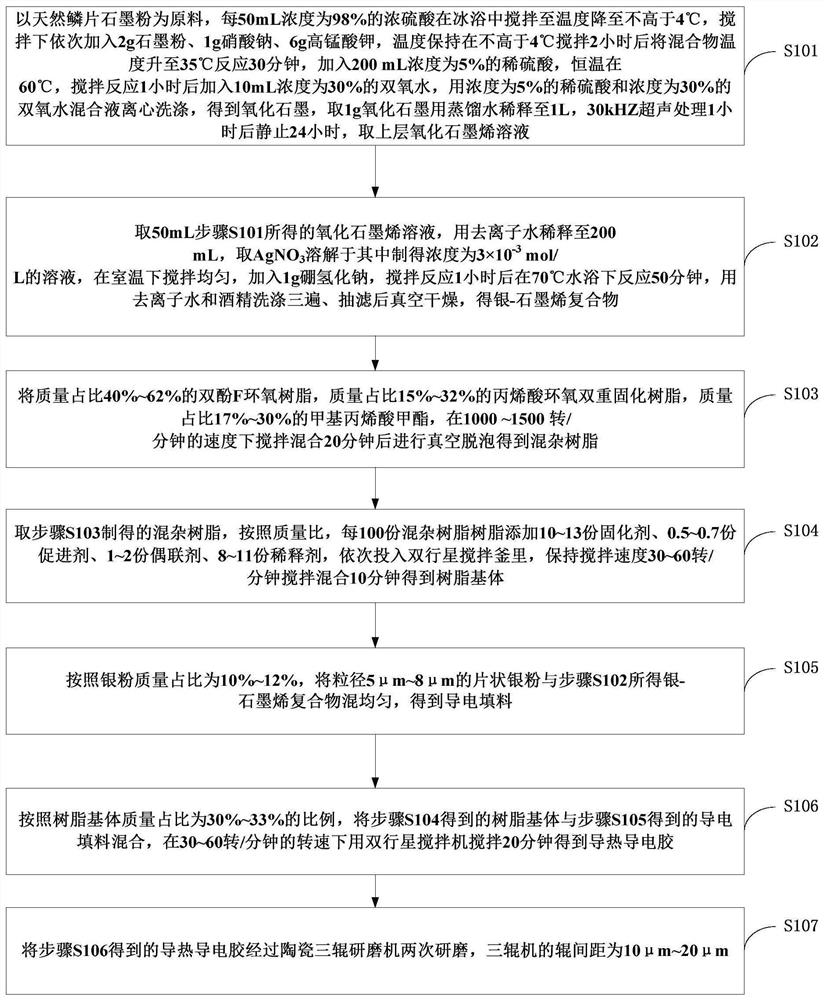

[0039] A preparation method of high thermal conductivity conductive adhesive comprises:

[0040] S101. Using natural flake graphite powder as raw material, stir every 50mL of concentrated sulfuric acid with a concentration of 98% in an ice bath until the temperature drops to no higher than 4°C. Add 2g of graphite powder, 1g of sodium nitrate, and 6g of permanganate in turn under stirring. Potassium, keep the temperature at no higher than 4°C and stir for 2 hours, then raise the temperature of the mixture to 35°C and react for 30 minutes, add 200mL of 5% dilute sulfuric acid, keep the temperature at 60°C, stir for 1 hour, then add 10mL of 30% sulfuric acid % hydrogen peroxide, centrifuged and washed with a mixture of 5% dilute sulfuric acid and 30% hydrogen peroxide to obtain graphite oxide, take 1g of graphite oxide and dilute it to 1L with distilled water, 30kHZ ultrasonic treatment for 1 hour and then stand still for 24 hours, take the upper layer Graphene oxide solution;

...

Embodiment 1

[0051] The mass ratio of the resin matrix is 30%;

[0052] The resin matrix includes hybrid resin, curing agent, accelerator, coupling agent, and diluent. According to the mass ratio, add 10 parts of curing agent, 0.5 parts of accelerator, 1 part of coupling agent, and 8 parts of diluent for every 100 parts of hybrid resin;

[0053] The hybrid resins include:

[0054] 40% bisphenol F epoxy resin DER354 by mass;

[0055] Acrylic epoxy dual curing resin with a mass ratio of 32%;

[0056] The mass accounts for 28% methyl methacrylate;

[0057] The conductive filler is a mixture of silver powder and a silver-graphene compound, the silver powder is flake silver powder with a particle size of 6 μm, and the mass ratio of the silver powder is 10%;

[0058] Under the above parameters, the measured resistivity of the thermally conductive adhesive is 1.1×10 -4 Ω·cm. At the same time, the thermal conductivity of the thermally conductive adhesive was tested, and the thermal conductiv...

Embodiment 2

[0060] The mass ratio of the resin matrix is 31%;

[0061] The resin matrix includes hybrid resin, curing agent, accelerator, coupling agent, and diluent. According to the mass ratio, 11.5 parts of curing agent, 0.55 parts of accelerator, 1.5 parts of coupling agent, and 10 parts of diluent are added for every 100 parts of hybrid resin;

[0062] The hybrid resins include:

[0063] Bisphenol F epoxy resin DER354 with a mass ratio of 55%;

[0064] Acrylic epoxy dual curing resin with a mass ratio of 25%;

[0065] 20% methyl methacrylate by mass;

[0066] The conductive filler is a mixture of silver powder and a silver-graphene compound, the silver powder is flake silver powder with a particle size of 6 μm, and the mass ratio of the silver powder is 11%;

[0067] Under the above parameters, the measured resistivity of the thermally conductive adhesive is 1.0×10 4 Ω·cm. At the same time, the thermal conductivity of the thermally conductive adhesive was tested, and the therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com