Integrated package structure for super power vertical chip

An integrated packaging, ultra-high power technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of limiting packaging power density, uneven distribution of gold wires, etc., achieve high thermal conductivity, and realize the effect of stable power supply with large currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The described embodiments are only some of the embodiments of the invention. All other embodiments without creative achievements based on the embodiments of the present invention belong to the protection scope of the present invention.

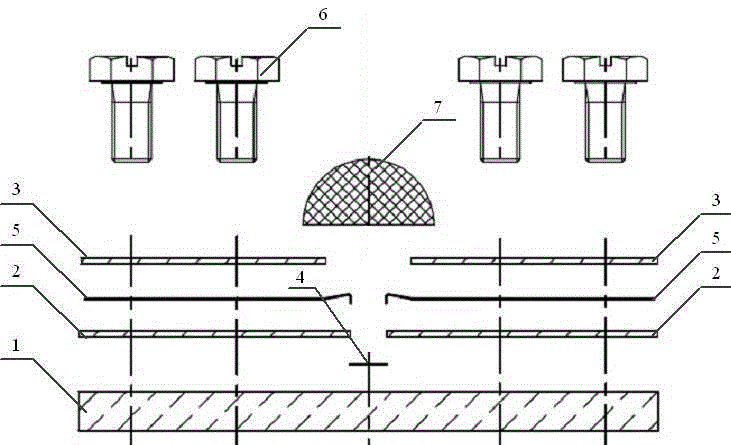

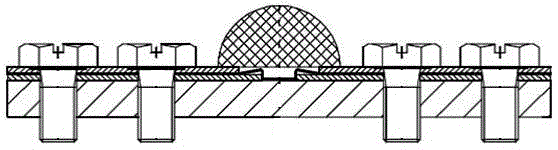

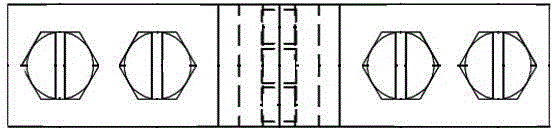

[0019] The integrated packaging structure of the ultra-high power vertical chip of the present invention, its assembly diagram is as follows figure 1 shown. The substrate of this packaging structure is composed of positive electrode conductive plate 1, insulating layer 2 and negative electrode conductive plate 3. The insulating layer 2 and the negative electrode conductive plate are slotted, and three UV LED vertical chips 4 rated at 35W are arranged in a straight line in the groove. The P-type electrode below the chip is eutectically welded to the positive conductive plate 1 , and the N-type electrode above the chip is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com