Substrate for holding at least one component and method for producing same

A technology for substrates and components, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as DCB substrate fracture, and achieve the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

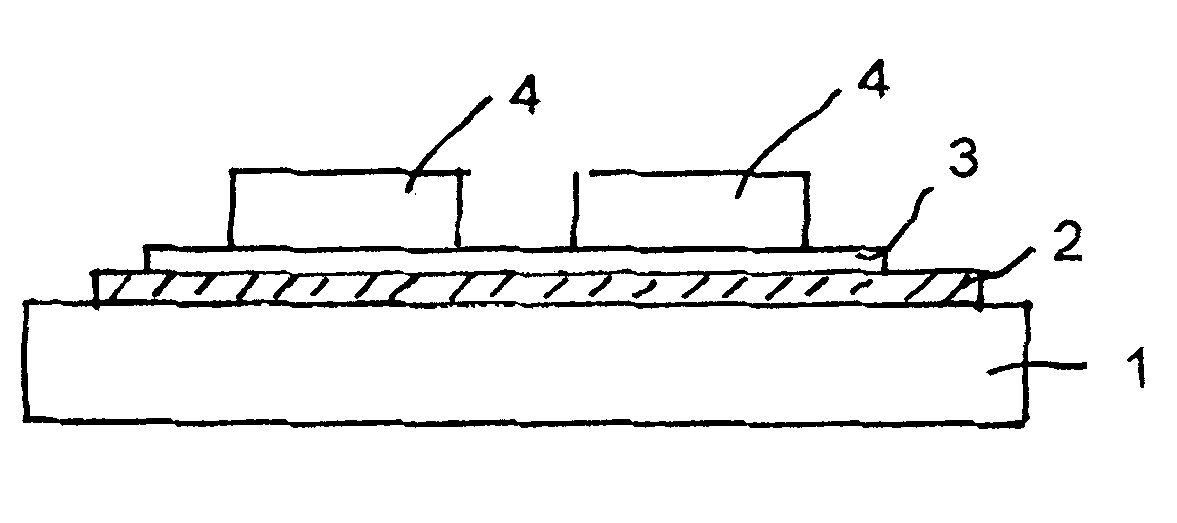

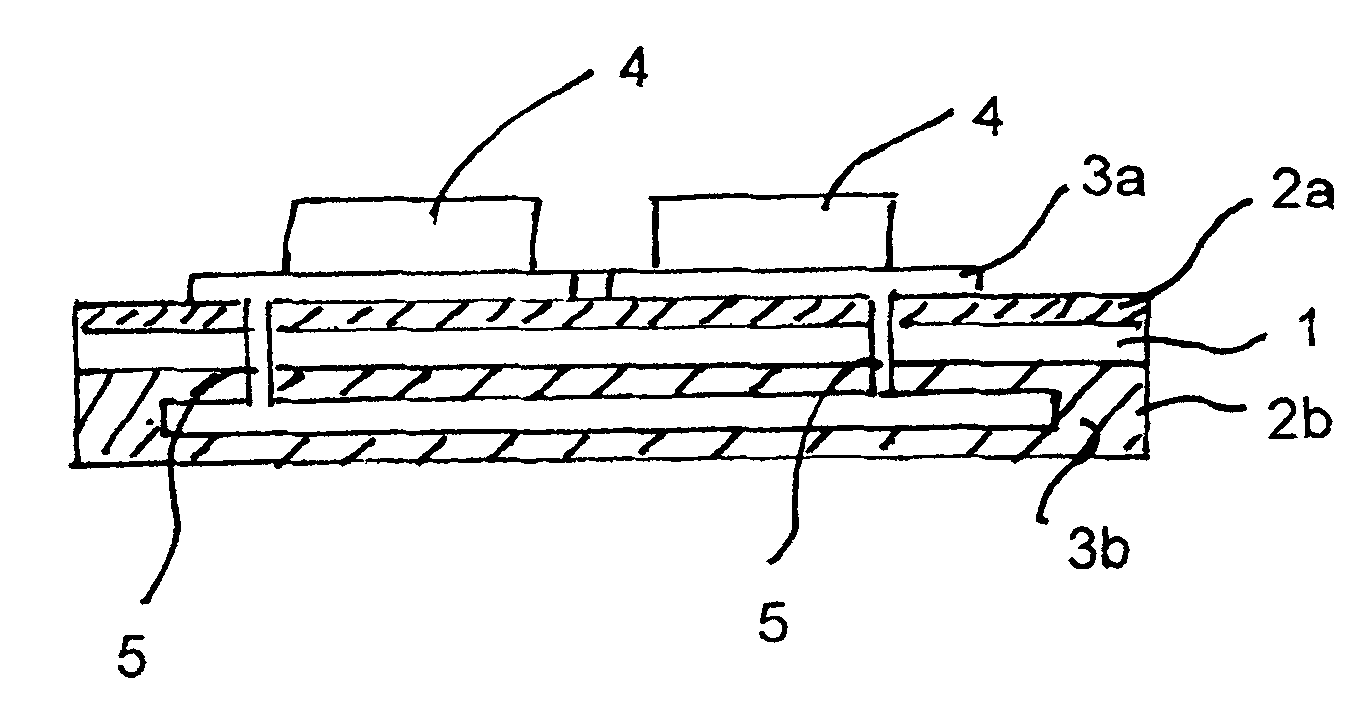

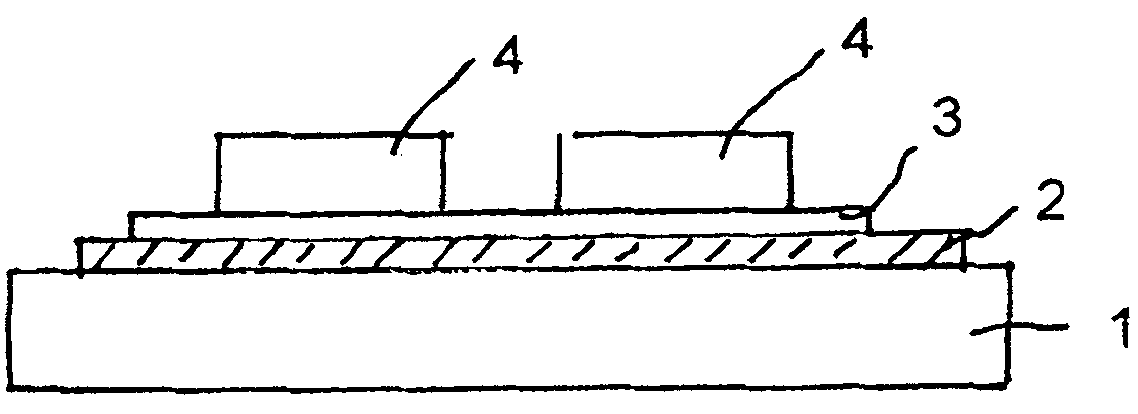

[0027] exist figure 1 In this case, a connection layer 2 is provided on the substrate body 1 . The connection layer 2 connects the conductive layer 3 with the substrate body 1 . The conductive layer 3 is connected to the element 4, and the conductive layer 3 may be a conductor line structure. The component 4 can be a semiconductor component, in particular a power semiconductor. The element 4 is connected to the conductive layer 3 , for example by means of a conventional solder connection.

[0028] The connection layer 2 is electrically insulating, preferably made of polysiloxane, which is filled with fillers up to a filling degree of 60% by volume to 80% by volume. The filler is suitably SiC having an average particle size in the range of 2 to 10 μm. Such a connection layer 2 has an excellent thermal conductivity λ of greater than 20 W / mK.

[0029] The substrate body 1 is made of metal, preferably a copper alloy or an aluminum alloy. The substrate body 1 can be produced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com