Thermal conductive sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

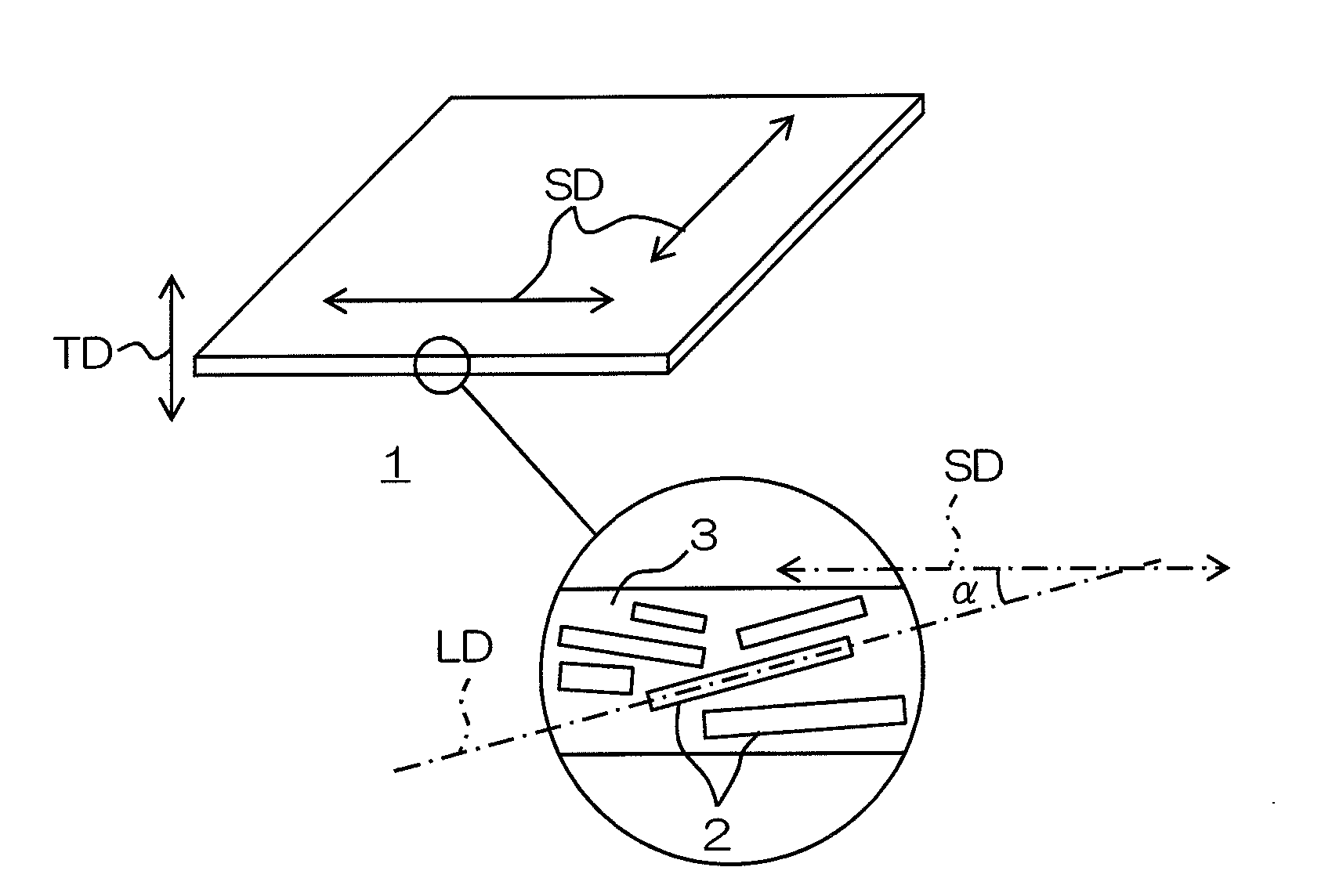

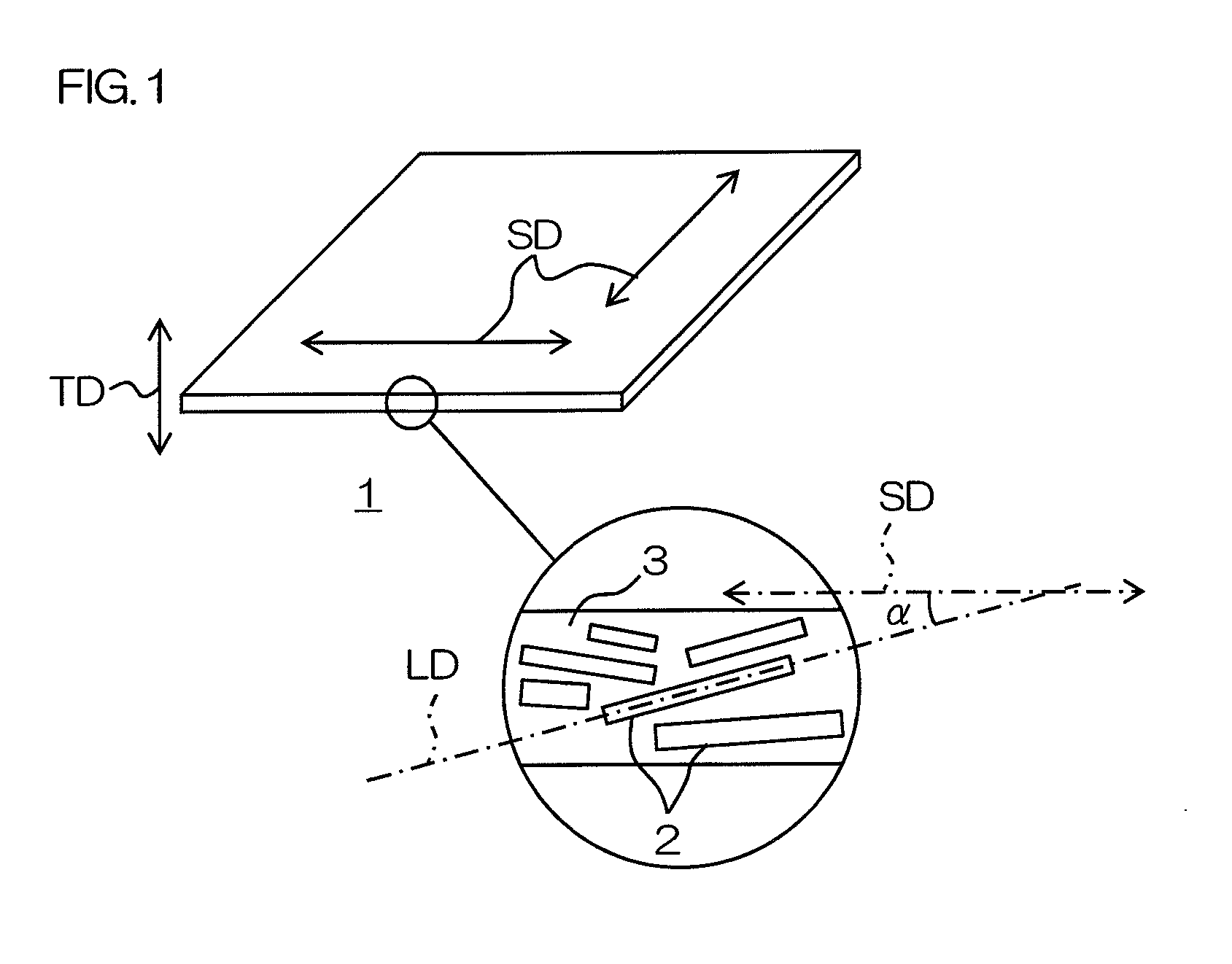

Image

Examples

example 1

[0166]The components described below were blended, stirred, and allowed to stand at room temperature (23° C.) for one night, thereby allowing methyl ethyl ketone (dispersion medium for the curing agent) to volatilize and preparing a semi-solid mixture. The details of the components are as follows: 13.42 g of PT-110 (trade name, plate-like boron nitride particles, average particle size (light scattering method) 45 μm, manufactured by Momentive Performance Materials Inc.), 1 g of jER®828 (trade name, bisphenol A epoxy resin, liquid, epoxy equivalent 184 to 194 g / eqiv., softening temperature (ring and ball method) below 25° C., melt viscosity (80° C.) 70 mPa·s, manufactured by Japan Epoxy Resins Co., Ltd.), 2 g of EPPN-501HY (trade name, triphenylmethane epoxy resin, solid, epoxy equivalent 163 to 175 g / eqiv., softening temperature (ring and ball method) 57 to 63° C., manufactured by NIPPON KAYAKU Co., Ltd), and 3 g (solid content 0.15 g) (5 mass % per total amount of epoxy resins of j...

examples 2 to 9 and 11 to 16

[0173]Thermal conductive sheets were obtained in the same manner as in Example 1 in conformity with the mixing formulation and production conditions shown in Table 1 to Table 3.

example 10

[0174]A mixture was prepared by blending and stirring components (boron nitride particles and polyethylene) in accordance with the mixing formulation of Table 2. That is, during the stirring of the components, the mixture was heated to 130° C., and polyethylene was melted.

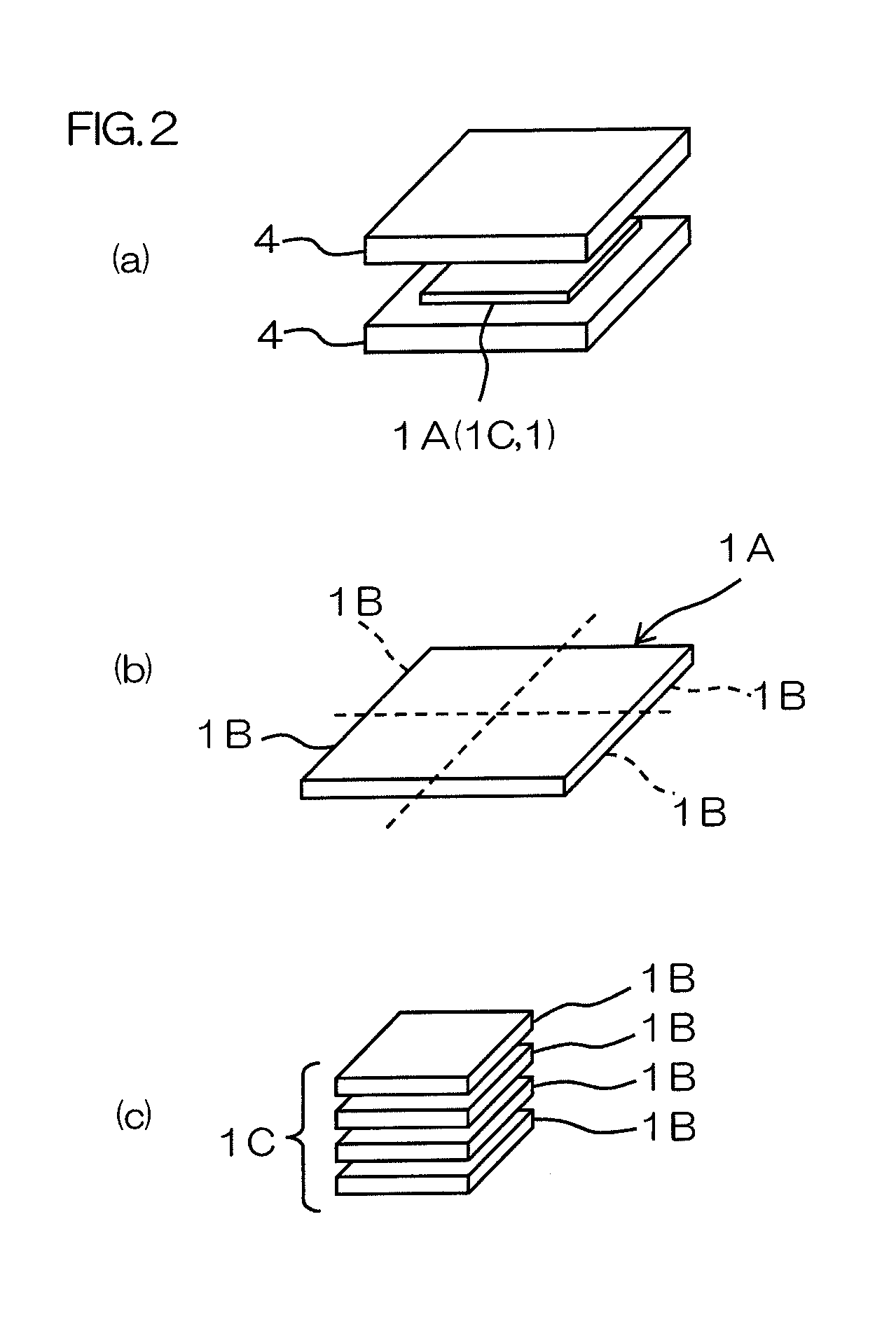

[0175]Then, the obtained mixture was sandwiched by two silicone-treated releasing films, and then these were hot-pressed with a vacuum hot-press at 120° C. under an atmosphere (vacuum atmosphere) of 10 Pa with a load of 1 ton (4 MPa) for 2 minutes. A pressed sheet having a thickness of 0.3 mm was thus obtained (ref: FIG. 2 (a)).

[0176]Thereafter, the obtained pressed sheet was cut so as to be divided into a plurality of pieces when projected in the thickness direction of the pressed sheet. Divided sheets were thus obtained (ref: FIG. 2 (b)). Next, the divided sheets were laminated in the thickness direction. A laminated sheet was thus obtained (ref: FIG. 2 (c)).

[0177]Then, the obtained laminated sheet was hot-presse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com