High-magnification niobium-tungsten oxide fast-charging electrode materials as well as preparation method and application thereof

An oxide, high-rate technology, applied in battery electrodes, circuits, secondary batteries, etc., to achieve the effect of increasing volumetric energy density and overcoming poor electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] NbO 2 (purchased from Alfa Aesar, 99+%) and WO 2 (purchased from Alfa Aesar, 99+%) was mixed according to the mass ratio of 16:5 and manually ground in a mortar for 1 h, then pressed into a block with a pressure of 10 MPa, and then placed in a metal platinum crucible at 10 ° C / Min heating rate is heated from room temperature to 1200 °C, and finally cooled to room temperature in air for about 2 hours to obtain a high rate niobium tungsten oxide fast charging electrode material Nb 16 W 5 o 55 .

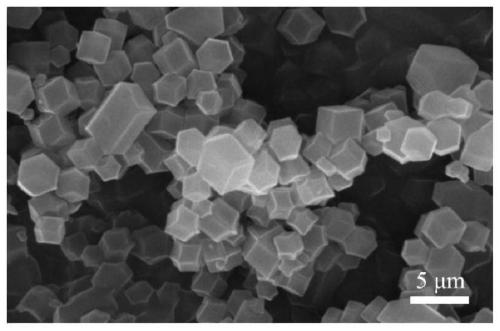

[0024] Such as figure 1 As shown, the electrode material Nb provided in the embodiments of the present invention 16 W 5 o 55 The shape is uniform and the size reaches the micron level.

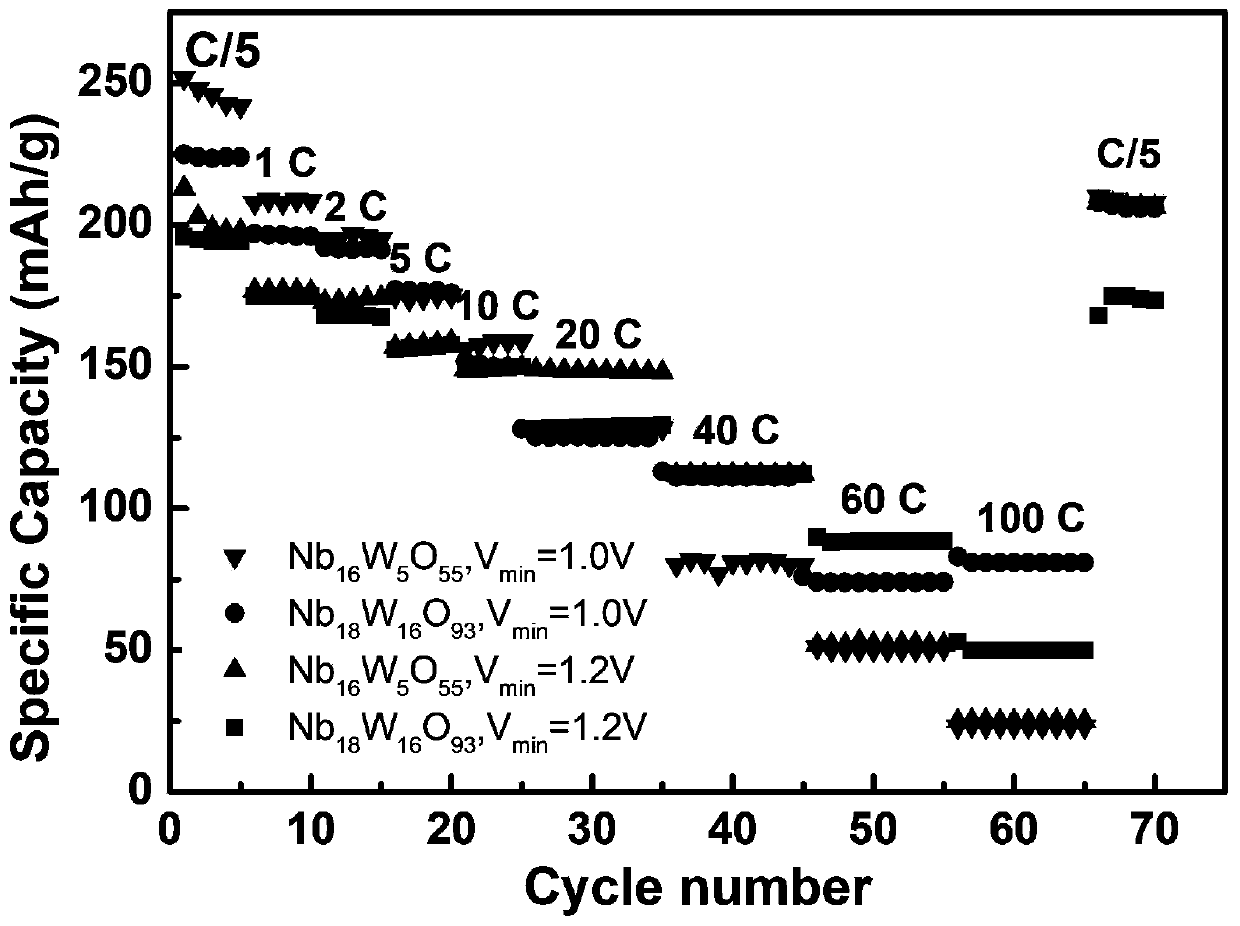

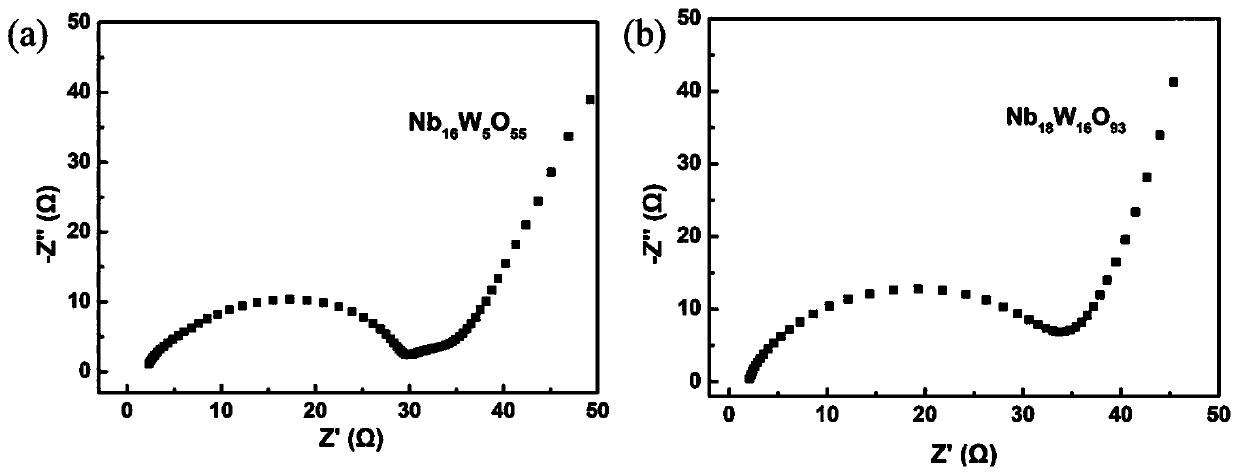

[0025] In the present invention, grind the above-mentioned electrode material with conductive agent acetylene black and binder PVDF (polyvinylidene fluoride) according to the mass ratio of 8:1:1, add solvent NMP (methylpyrrolidone) for half an hour, and stir at room temperature Prepare...

Embodiment 2

[0028] NbO 2 (purchased from Alfa Aesar, 99+%) and WO 2 (purchased from Alfa Aesar, 99+%) was mixed according to the mass ratio of 18:16 and manually ground in a mortar for 1 h, then pressed into a block with a pressure of 10 MPa, and then placed in a metal platinum crucible at 10 ° C / Min heating rate is heated from room temperature to 1200 °C, and finally cooled to room temperature in air for about 2 hours to obtain a high rate niobium tungsten oxide fast charging electrode material Nb 18 W 16 o 93 .

[0029] In the present invention, grind the above-mentioned electrode material with conductive agent acetylene black and binder PVDF (polyvinylidene fluoride) according to the mass ratio of 8:1:1, add solvent NMP (methylpyrrolidone) for half an hour, and stir at room temperature Prepare a slurry for 6 hours, and then evenly coat the prepared slurry on the copper foil with a scraper to prepare a pole piece. The pole piece is punched into a disc and used as a working electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com